Carbon emission assessment of lithium iron phosphate batteries

Nov 1, 2024 · In the past, CBS systems used lead-acid batteries as energy storage, which posed challenges related to space consumption and low energy density. With the ongoing

Comparative Lifecycle Analysis: Lithium Iron Phosphate and Lead-Acid

Aug 8, 2025 · The comparison between Lithium Iron Phosphate (LiFePO4) and Lead-Acid batteries represents a significant milestone in this evolution, showcasing the shift towards

Comparison of Lead-Acid and Lithium Ion Batteries for

Dec 26, 2023 · The various properties and characteristics are summarized specifically for the valve regulated lead-acid battery (VRLA) and lithium iron phosphate (LFP) lithium ion battery.

Comparative life cycle assessment of different lithium

Aug 25, 2021 · One of the technologies that are gaining interest for utility-scale energy storage is lithium-ion battery energy storage systems. However, their environmental impact is inevitably

Lead-Acid vs. Lithium Iron Phosphate (LFP)

May 7, 2025 · As of 2023, LFP captures 38% of the stationary storage market that lead-acid once ruled, while costing just 2.1x more per kWh upfront but lasting

Design and control of the hybrid lithium-ion/lead–acid battery

Oct 1, 2023 · This paper presents design and control of a hybrid energy storage consisting of lead–acid (LA) battery and lithium iron phosphate (LiFePO4, LFP) battery, with built-in

Lithium Iron Phosphate Battery vs Lead Acid –

Jul 8, 2024 · In the world of energy storage, choosing the right battery technology is crucial for ensuring efficiency, longevity, and safety. Two of the most

Comparison of Lead-Acid and Lithium Ion Batteries for

Dec 26, 2023 · Rechargeable batteries have widely varying efficiencies, charging characteristics, life cycles, and costs. This paper compares these aspects between the lead-acid and lithium

Differences between SLA and LiFEPO4 batteries

Apr 26, 2023 · For that reason, Nature''s Generator put together a quick primer on two of the most significant types of batteries currently in use in solar + storage

A comparison of lead-acid and lithium-based battery

Oct 1, 2013 · The effects of variable charging rates and incomplete charging in off-grid renewable energy applications are studied by comparing battery degradation rates and mechanisms in

Comparison of lead-acid and lithium ion batteries for

Jan 1, 2016 · The various properties and characteristics are summarized specifically for the valve regulated lead-acid battery (VRLA) and lithium iron phosphate (LFP) lithium ion battery. The

Home Solar Storage: Lead-Acid Batteries VS Lithium Iron Phosphate Batteries

Mar 3, 2025 · In the home solar energy storage space, two main contenders are vying for dominance: lead-acid batteries and lithium iron phosphate (LiFePO4) batteries. Each type of

Lead-Acid vs. Lithium Iron Phosphate (LFP)

May 7, 2025 · Since Gaston Planté invented the lead-acid battery in 1859, it has dominated global energy storage with its simplicity and low upfront cost. But

Implementing Lithium Iron Phosphate Battery Systems Simply

2 days ago · The transition to Lithium Iron Phosphate battery systems represents a clear path forward for businesses seeking reliable, sustainable energy storage solutions. With

Comparison of lead-acid and lithium ion batteries for

Nov 15, 2016 · This paper compares these aspects between the lead-acid and lithium ion battery, the two primary options for stationary energy storage. The various properties and

Lithium Iron Phosphate (LFP) vs. Lithium-Ion Batteries

Jul 10, 2024 · In the rapidly evolving landscape of energy storage, the choice between Lithium Iron Phosphate (LFP) and conventional Lithium-Ion batteries is a critical one. This article

Lead-Acid to Lithium Battery: The Best LiFePO4 Replacement

1 day ago · A lead-acid to lithium battery refers to replacing traditional lead-acid batteries with LiFePO4 (Lithium Iron Phosphate) batteries. This solution is widely used in UPS systems,

Best practice guidance for storage, handling and

Feb 16, 2025 · Australian Battery Industry Association Best practice guidance for storage, handling and disposal of lead acid and lithium phosphate batteries

Sealed Lead Acid (SLA) Batteries Compared to Lithium

Jun 26, 2020 · Sealed Lead Acid (SLA) batteries have ruled the market because of their low cost. Lithium Iron Phosphate (LFP) batteries had grown in popularity in the last decade and have

Lithium Iron Phosphate Battery Vs. Lead-Acid Battery: Which

Feb 19, 2025 · Lithium Iron Phosphate (LiFePO₄) and Lead-Acid batteries are two common types of batteries used in energy storage. While both are widely used, they have significant

Life cycle assessment of electric vehicles'' lithium-ion batteries

Nov 1, 2023 · Koh et al. [26] evaluated the energy storage systems of lithium titanate (LTO) batteries, lithium iron phosphate batteries, lead-acid batteries, and sodium-ion batteries with

Lithium Iron Phosphate Battery vs Lead Acid: Key

Oct 30, 2024 · Lithium iron phosphate batteries are seen as a better choice for the Earth when compared to acid batteries. These batteries last longer, and

Past and Present of LiFePO4: From Fundamental Research to

Jan 10, 2019 · In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The

6 FAQs about [Energy storage lead-acid batteries and lithium iron phosphate]

What is a lithium iron phosphate (LFP) battery?

Lithium Iron Phosphate (LFP) batteries had grown in popularity in the last decade and have made and lead-acid and lithium-iron are leading batteries used in residential and commercial energy storage applications. Besides using different chemistry, the SLA and LFP batteries vary in terms of the cost of ownership and performance.

Which battery type is best for energy storage?

In the realm of energy storage, LiFePO4 (Lithium Iron Phosphate) and lead-acid batteries stand out as two prominent options. Understanding their differences is crucial for selecting the most suitable battery type for various applications.

Can a lithium-ion battery be combined with a lead-acid battery?

The combination of these two types of batteries into a hybrid storage leads to a significant reduction of phenomena unfavorable for lead–acid battery and lower the cost of the storage compared to lithium-ion batteries.

Why are lead acid batteries so popular?

Sealed Lead Acid (SLA) batteries have ruled the market because of their low cost. Lithium Iron Phosphate (LFP) batteries had grown in popularity in the last decade and have made and lead-acid and lithium-iron are leading batteries used in residential and commercial energy storage applications.

Does lithium iron phosphate solution-based battery need to be replaced during Operation?

Lithium Iron phosphate solution-based is not replaced during operation (3000 cycles are expected from the battery at 100% DoD cycles) The cost per cycle, measured in € / kWh / Cycle, is the key figure to understand the business model.

Are lithium iron phosphate batteries better than SLA batteries?

Lithium Iron Phosphate (LFP) batteries provide lower long-term cost of ownership over SLA batteries. The average upfront cost of LFP battery today is about 3.5X of comparable SLA and it has 7X longer cycle life. Both SLA and LFP batteries are both designed to be safe to use and are safe for the environment.

Update Information

- Skopje energy storage battery lithium iron phosphate

- Energy storage cabinet lithium iron phosphate

- Solar Energy Storage Lithium Iron Phosphate

- Photovoltaic energy storage lithium battery lithium iron phosphate

- Energy storage lithium iron phosphate battery life

- Lithium iron phosphate single 12v energy storage battery

- Danish lithium iron phosphate energy storage battery cabinet

- Ghana lithium iron phosphate energy storage battery

- Bulgaria s energy storage choice is lithium iron phosphate battery

- Home Energy Storage Lithium Iron Phosphate

- Energy storage lithium iron phosphate and lead carbon battery

- Lomei lithium iron phosphate portable energy storage device

- Energy storage power station is lithium iron phosphate

Solar Storage Container Market Growth

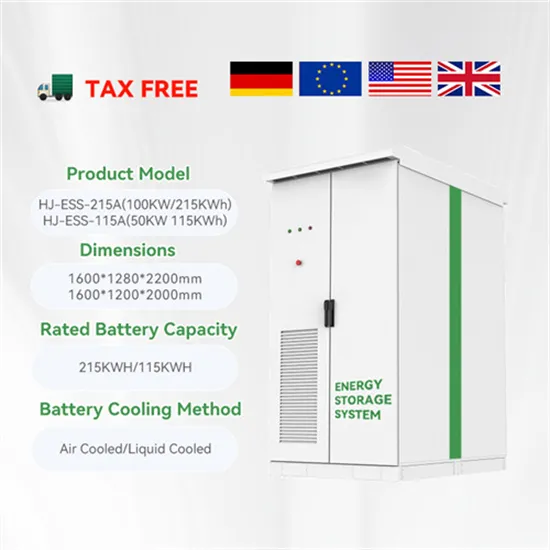

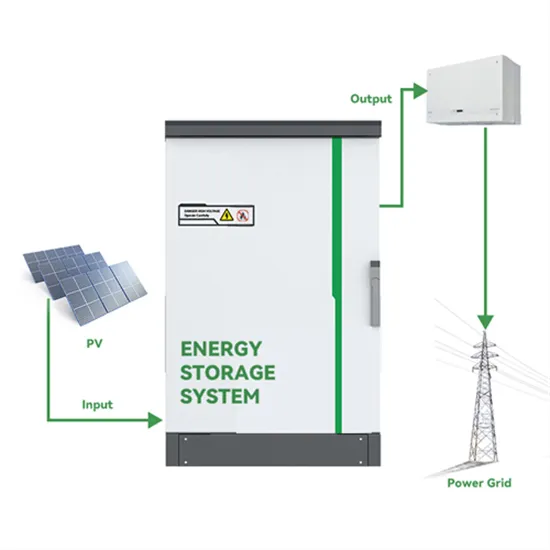

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.