Shanghai Zonzsin Intelligent Equipment Co., Ltd.-Power Battery

Shanghai Zonzsin Intelligent Equipment Co., Ltd. focuses on serving the power battery, energy storage system industry and photovoltaic industry, providing customers with professional

Battery Manufacturing Equipment Providers

Aug 3, 2025 · This overview introduces the key players and established companies in Battery Manufacturing Equipment, along with additional information on their technologies and market

Battery Pack Assembly Equipment Manufacturer, Battery Test Equipment

Founded in 2011, WinAck Battery has always focused on the R&D and production of battery pack assembly equipment and battery testing equipment. More professional, we can provide

Portable Battery Pack Charge/Discharge Maintenance Equipment

The PBM-MW series portable battery pack charge and discharge maintenance instrument is a small charge and discharge device that meets the functions of charging, discharging and

Intelligent Manufacturing

Oct 14, 2019 · In response to the production of new energy electric vehicle battery power system requirements, Shanghai Electric Anwha can provide intelligent module and battery pack

Battery guidance document

Feb 3, 2025 · These are portable units, commonly referred to as "battery packs" or "power packs," primarily designed to supply power to other devices or equipment. For the purposes of these

Battery Production | AVL

Aug 18, 2025 · To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Saic-gm plant_Cases_BESFIT (Shanghai) Intelligent Equipment

Aug 18, 2025 · Saic GM U557E PHEV Battery PACK assembly line: The whole line adopts 6-axis robot automatic gluing and tightening, uses high-precision 2D and 3D visual positioning and

Battery Lab Equipment for Lithium-ion Manufacturing | Targray

Aug 18, 2025 · Targray Battery Lab Equipment is supplied to lithium-ion battery developers for the production of various energy storage technologies. Our catalog offers customized high efficient

Module/Pack Testing | Arbin Instruments

2 days ago · Module and pack battery formats are critical for electrification in the transportation and energy industries. Arbin Instruments'' module and pack test equipment is engineered to

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · ng of Li-ion battery packs is a dynamic industry in India. Advanced equipment and machinery are available to assemble high quality packs with reliable and quality performance

Battery Packs Explained: How They Work, Usage, and a

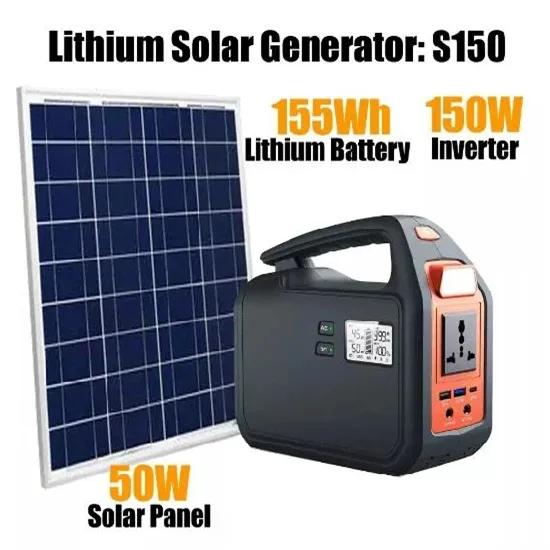

Feb 28, 2025 · What Are Battery Packs and How Do They Work? Battery packs are portable power sources that store electrical energy for later use. They typically consist of multiple

Automotive Battery Pack Standards and Design

Apr 7, 2025 · Fig. 1 shows the ideal battery pack and major constraints. The battery pack, as the main energy storage device for EVs, delivers the required energy and power with a reliable

What is a Battery Pack?

Jul 7, 2025 · The term "battery pack" is commonly used for devices like cordless tools, electric toys, and battery electric vehicles (BEVs). Each pack is a self-contained unit that houses

China Battery Pack Assembly Line, Battery Pasting Machine

Aug 13, 2025 · Xiamen Acey New Energy Technology Co.,Ltd: Expert of electric vehicle battery making solution, lithium ion battery pack assembly line, battery module assembly consultation,

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

6 FAQs about [Battery pack related equipment]

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What is the main business of a battery pack assembly company?

The main business is to provide solutions for the lithium battery pack assembly production line, include: battery insulation paper sticking machine, battery cell sorting machine, battery spot welding machine, battery test equipment, battery PCM tester, battery BSM tester

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

What are the components of a battery pack?

Busbars and Soft Connections: For electrical connections between cells. Protection Board: Includes the Battery Management System (BMS), responsible for battery protection and monitoring. Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices.

What makes a good battery pack?

Whether you’re a professional or a curious reader, this guide will provide a clear and detailed overview. The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack.

Update Information

- Egypt lithium battery pack assembly equipment

- What equipment will be used for lithium battery pack

- Pack automatic battery packing equipment

- Lithium battery single string pack equipment

- Battery pack and electrostatic protection

- Helsinki lithium battery pack series connection

- Bangkok LiFePO4 battery and lithium battery pack

- Condensation inside the battery pack

- Battery independent pack

- Nanya lithium battery pack

- How long does it take to customize a lithium battery pack

- New Zealand lithium battery pack

- Southern Europe lithium battery pack supplier

Solar Storage Container Market Growth

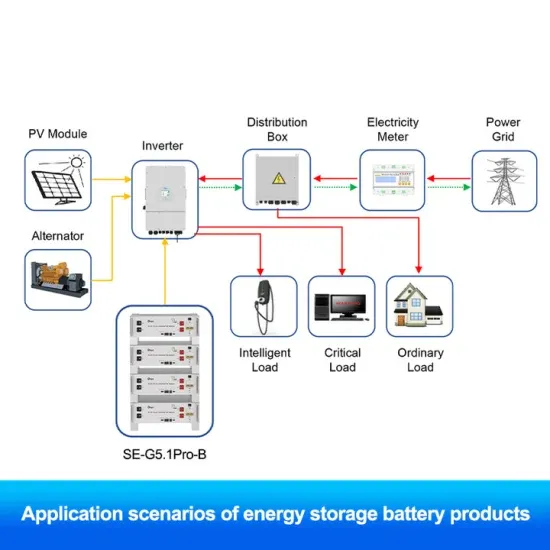

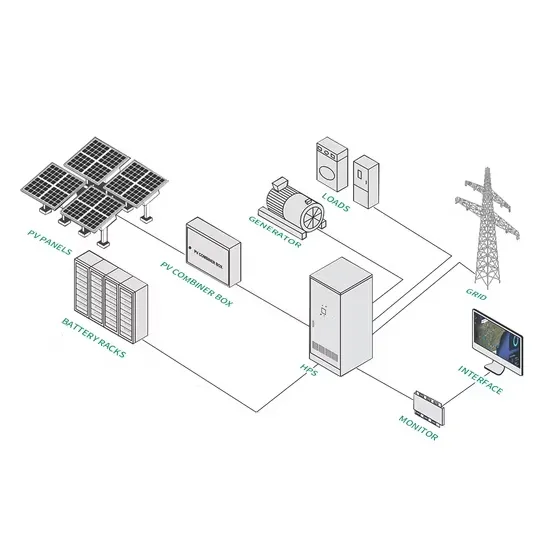

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.