Battery Circuit Architecture

Aug 6, 2011 · I. TYPICAL BATTERY CIRCUITRY FOR A LI-ION BATTERY PACK Fig. 1 is a block diagram of circuitry in a typical Li-ion battery pack. It shows an example of a safety protection

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

Battery voltage transfer method for multi-cells Li-ion

Aug 11, 2022 · In order to suppress leakage current caused in the traditional multi-cells series Li-ion battery pack protection system, a new battery voltage transfer method is presented in this

PROTECTING RECHARGEABLE LI-ION AND LI-POLYMER

overtemperature protection and overcurrent protection. ICs and MOSFETs are often used as the primary pack protection in conjunction with a fuel gauge device to track the battery cell

ESD – Electrostatic Discharge: Phenomenon, Effects, and Protection

May 25, 2025 · ESD – Electrostatic Discharge: Phenomenon, Effects, and Protection Discover what ESD is, how it happens, and how to protect electronics from its damaging effects.

System-Level ESD Protection Guide (Rev

Aug 5, 2025 · ABSTRACT Electrostatic discharge (ESD) poses a risk to many electronic devices and can cause unexpected and catastrophic damage. While many ICs have device level ESD

BQ76942 IEC ESD 61000-4-2 Test Report

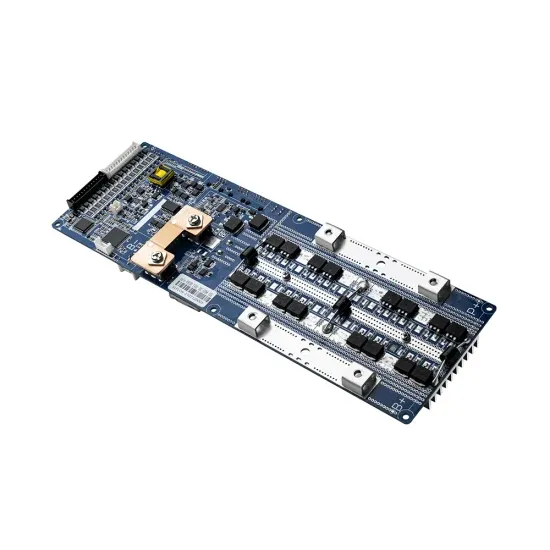

1.2 BQ76942 Overview The Texas Instruments BQ76942 is a highly integrated, high accuracy battery monitor and protector for 3-series to 10-series Li-Ion, Li-Polymer, and LiFePO4 battery

Functional modules and electrostatic surge protection of battery

Fault Diagnosis and Safety Protection Unit: responsible for detecting battery pack faults and taking corresponding safety protection measures. It can monitor abnormal situations such as

Efficient and lightweight battery protection film with a bionic

Feb 15, 2025 · Under the problematic global climate change situation, electric vehicles are rapidly developing due to the advantages of environmental protection, low noise, and simple

Presentation Title Here

5 days ago · More advanced battery packs may need additional features such as cell balancing, high side FET drive to allow communication with protections triggered, battery monitoring for

Battery protection selection guide

May 24, 2025 · Battery protection unit The battery protection circuit disconnects the battery from the load when a critical condition is observed, such as short circuit, undercharge, overcharge

Battery Protection Circuit of Different Battery Chemistries

Apr 16, 2025 · Battery protection circuits play a crucial role in maintaining the safety, performance, and lifespan of your battery. These circuits shield batteries from overcharging, over

Experimental Study on External Short Circuit and

Mar 9, 2020 · In this study, three contributions are made: (1) Battery cells with ten different SOCs (10%, 20% 100%) are short-circuited at three ambient temperatures of, and to investigate the

Battery Coatings Enhancing EV Performance and Safety

Bending the laws of physics Peter Donaldson finds complex challenges within the development of coatings for battery applications Coatings play a crucial role in battery cells, modules and

A protection chip for three lithium cells

Nov 26, 2021 · This paper designs a 3-cell lithium battery charge and discharge protection chip based on the 0.18 µm Bipolar-CMOS-DMOS (BCD) process. The measurements indicate that

Protection Circuit Design of Lithium-Ion Battery Pack Based

This paper describes a protection circuit based on the STM32F103 processor used for a power lithium battery pack. The protection circuits from overcharge voltage and current and short

Space-efficient protection for cylindrical batteries embedded

Apr 1, 2024 · In the present study, we proposed a space-efficient protecting approach of filling the gaps in cylindrical battery pack with protective materials. The mechanical and electrical

Lithium-Ion Battery Fire Suppression in EVs

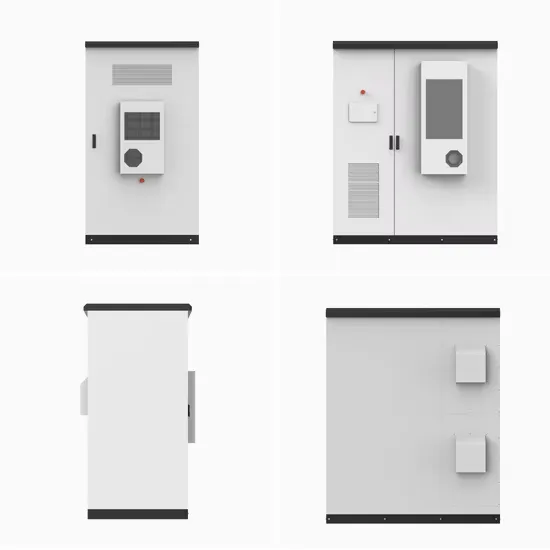

Jul 31, 2025 · These systems house battery packs in fire protection cabinets spatially separated from occupied areas and connected to overhead dielectric fluid tanks. During normal

R16AN0049EU: Importance of Grounding in Battery

Jul 2, 2024 · Importance of Grounding in Battery Management Systems This application note explores the crucial role of grounding in battery management systems (BMS). It starts with

Lithium battery protection board EK

Jul 29, 2025 · 2.This series of lithium battery protection boards uses automotive-grade MOS, 2oz thickened copper foil and copper strips for current sharing, making the protection board highly

Electrostatics and ESD Testing: How We Protect

Mar 25, 2025 · Electrostatic discharges (ESD) are an invisible but serious threat to electronic systems. Especially in safety-critical applications such as medical

电池管理系统bms的功能模块及静电浪涌防护

电池管理系统(Battery Management System,BMS)是用于监测、控制和保护锂离子电池(Li-ion Battery)的关键组成部分。 下面是电池管理系统功能的具

Mitigation strategies for Li-ion battery thermal runaway: A

Oct 1, 2021 · IEEE 1725–2011 lists "protection circuitry" as additional risk mitigation approaches against overvoltage, under-voltage, electrostatic discharge, and overcurrent for both single

Electrochemical and Electrostatic Energy Storage and

Sep 19, 2017 · look ahead toward promising advanced battery chemistries and next generation ESS. Energy management systems and various battery balancing configurations are

6 FAQs about [Battery pack and electrostatic protection]

What type of batteries does this protection circuit apply to?

This protection circuit is generally used for rechargeable lithium batteries and where there will be multiple cells within the battery pack. Protection circuits embedded into battery packs provide full-time protection that is active throughout the lifecycle of the battery.

Can this protection circuit module be used with non-lithium batteries?

This protection circuit module can also function using non-lithium battery chemistries that do not require a protection circuit when in use or when discharging. Some advantages with having the protection circuit module in the battery charger is that only one protection circuit module will be required, and it can reduce costs when using multiple batteries.

What is a safety circuit in a Li-ion battery pack?

Fig. 1 is a block diagram of circuitry in a typical Li-ion battery pack. It shows an example of a safety protection circuit for the Li-ion cells and a gas gauge (capacity measuring device). The safety circuitry includes a Li-ion protector that controls back-to-back FET switches. These switches can be

When does a protection circuit embedded in the battery charger work?

A protection circuit embedded into the battery charger will only provide protection to the battery cells when the charger is connected. The reason for this design method is to decrease the overall weight for the battery pack.

What is a protection circuit module?

A protection circuit module is designed to safeguard lithium-based battery chemistries from overcharging and over-discharging. These modules may also include additional features like short circuit protection, temperature protection, electrostatic discharge protection, and power management.

What is a protection circuit?

A protection circuit is a component embedded into battery packs that provides full-time protection throughout the lifecycle of the battery.

Update Information

- Lithium battery pack low voltage protection

- Türkiye pack lithium battery

- Greek battery pack manufacturer

- Caracas home battery pack

- Lightning protection for battery energy storage stations

- 4 strings of 12v lithium battery pack

- Energy storage protection battery

- 8 7 4v lithium battery pack

- Plug-in device for lithium battery pack

- Pack battery factory construction feasibility

- 6v200a lithium battery pack price

- Oslo LiFePO4 Battery Pack

- Energy storage cabinet battery cluster and pack

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.