Water Condensation in Traction Battery Systems

Mar 26, 2019 · Using a liquid or an evaporative cooling system can result in the condensation of water inside the battery system. Condensation occurs if the temperature of the cooling plate is

Battery pack condensation prevention

A battery control system for an electric vehicle including a battery pack includes a dew point calculation module that receives at least a first signal indicative of humidity within the battery

Condensation Failure Inside Battery Pack (BMS_F107 code)

Dec 6, 2013 · Regarding pack interior health, probably largely depends on how to pack is used in moisture settings. @mr_hyde 2015 pack had no seam leaks and simply died from moist air

Method of preventing condensation of battery pack

A method of preventing condensation of a battery pack in an eco-friendly vehicle including measuring a temperature of the battery pack provided in the eco-friendly vehicle and a

A closer look at humidity control methods for EV

Jul 29, 2021 · The latter approach has been used with success on a DC fast charger, according to Stego, though it would be a tough sell to put any kind of

Method Of Preventing Condensation Of Battery Pack

A method of preventing condensation of a battery pack in an eco-friendly vehicle includes measuring a temperature of the battery pack provided in the eco-friendly vehicle and a

Understanding Pack-Integrated Humidity Sensors:

Aug 6, 2025 · This blog post explores the crucial role of humidity sensors in battery technology, particularly in sealed battery assemblies. It highlights how these sensors monitor moisture

Battery pack water condensation mitigation

The present disclosure relates to battery packs and, more particularly, to a water-condensation mitigation system for a battery pack by reducing the relative humidity inside a battery pack and

Simulation of hybrid air-cooled and liquid-cooled systems

Dec 15, 2024 · Considering the challenges of condensation in battery thermal management systems, particularly in high-humidity conditions, this paper introduces a novel approach: a

Battery pack water cooling to prevent condensation

The BSM uses the humidity sensor to calculate the dew point of the coolant tubes inside the battery and help calculate cooling in the pack to prevent condensation and excessive moisture

Battery Pack Sealing and Protection

Apr 22, 2024 · The amount of diurnal breathing volume is dependent on the air volume inside the pack. The more volume, the greater potential for additional accumulation of condensation

Water Condensation in Traction Battery Systems

Apr 12, 2019 · To ensure the safe operation of lithium-ion cells, and to prolong their lifespan, hybrid and electric vehicle battery systems are equipped with cooling systems. Using a liquid

Temperature–Humidity Coupled Analysis in Battery Pack

Aug 13, 2021 · Finally, a practical case study on a battery pack is used to analyze dynamic characteristics of the temperature–humidity during idle and working. Using the coupling model

Theoretical and experimental investigations on liquid

Jun 15, 2024 · With the increasingly severe challenges of the thermal management of battery packs for electric vehicles, the liquid immersion cooling technology has

Pressure, absolute humidity and condensation

Download scientific diagram | Pressure, absolute humidity and condensation measurements for the sealed battery system (without a PCE) during normal operation: (a) Pressure in the

6 FAQs about [Condensation inside the battery pack]

Can a battery pack thermal management system reduce condensation?

This paper introduces an innovative battery pack thermal management system that combines air and liquid cooling with a return air feature to mitigate condensation in traditional models.

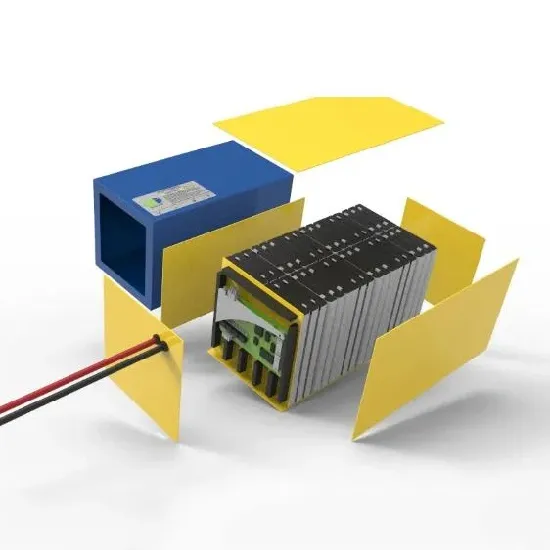

How do battery pack liquid absorbers work?

Battery Pack Liquid Absorbers from Freudenberg prevent this by reliably absorbing liquids inside battery packs. Liquids leaking inside a battery pack can have a variety of causes. The humidity of the air is one major issue. Air enters into the battery pack, and moisture condenses inside the cooled pack.

Why is condensation a problem in a liquid cooling system?

This leads to a significant increase in the heat exchange area required for liquid cooling systems and a continuous reduction in the supply water temperature, especially in high-humidity environments, potentially causing a serious issue: condensation.

What are the problems with a Freudenberg battery pack liquid absorber?

Another problem is coolant leaking out of the cooling system. In both cases, the absorbing fleece acts as a safety system to reliably capture and retain condensate and leaking coolant. Freudenberg developed its Battery Pack Liquid Absorbers as absorbent pads that can reliably take up and store large volumes of liquid.

Why is my car battery leaking?

Liquids leaking inside a battery pack can have a variety of causes. The humidity of the air is one major issue. Air enters into the battery pack, and moisture condenses inside the cooled pack. Another problem is coolant leaking out of the cooling system.

How does a battery cooling system work?

Upon completing the battery cooling process, the air passes through the piping system to the lower part of the liquid cooling plate to prevent condensation and then exits through the outlet. The entire process constitutes an anti-condensation cooling mechanism.

Update Information

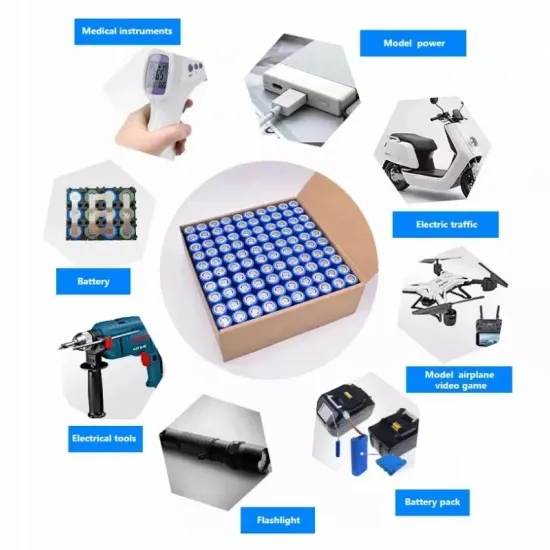

- Nassau st lithium battery pack

- Belarus Gomel ups power supply lithium battery pack

- Lithium battery pack safety design

- Plug-in device for lithium battery pack

- Oslo LiFePO4 Battery Pack

- Dxhc01 lithium battery pack

- Lithium battery pack base project

- Lithium battery pack traders

- Pack future lithium battery

- Peru new energy battery pack module design

- Lithium battery pack life

- Production of lithium battery pack types

- Juba lithium iron phosphate battery pack

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.