Illustrated explanation of the battery cabinet production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

Battery cabinets are process materials

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Exploring the World of Cabinet Type Energy Storage Battery

Jun 15, 2024 · At the core of every cabinet type energy storage battery factory lies a commitment to cutting-edge technology and meticulous design. These facilities are designed to optimize

Production planning and process optimization of a cell

Jan 1, 2022 · In the layout of battery cell manufacturing, the formation process is a cost and area intensive process step. Different process parameters significantly influence the machine

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

With the official launch of the All-New Elementa battery cabinet

May 10, 2022 · Trina Storage is further ramping up battery manufacturing capacity to strengthen vertical integration, lower average cost through economies of scale as well as improve cell

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

Illustrated explanation of the battery cabinet production

What is a battery formation process? s involves the battery''s initial charging and discharging cycles. This step helps form the solid electrolyte interphase (SEI) layer,which is crucial for

Energy storage cabinet base production process

Lithium battery energy storage cabinets play a crucial role in this process by storing excess energy generated during peak production times and discharging it during The energy

Lithium Battery Manufacturing Process Step-by-Step

Aug 4, 2025 · Ufine Battery lithium battery manufacturing process: electrode prep, cell assembly an''d testing. Custom solutions for high-performance batteries.

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids. But here''s the

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · Production Process of an All-Solid-State Battery Cell The publication "Production Process of an All-Solid-State Battery Cell" presents manufacturing technologies and chains for

Clean/Dry Rooms for Lithium Ion Battery Manufacturing

Aug 10, 2021 · Manufacturing Process The exact reaction that generates the electrons varies, depending on the type of battery. In a lithium-ion battery, you''ll find pressurized containers that

From Raw Materials to Reliable Power: Inside the Energy

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Dry Rooms and Lithium-Ion Battery Manufacturing

Jul 31, 2024 · Angstrom Technology''s Dry Room Solutions for Lithium-Ion Battery Manufacturing At Angstrom Technology, we specialize in designing and delivering efficient dry rooms tailored

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · Segments of the production line The production line of a battery modules and packs has three main areas with major differences in terms of batch sizes, process speeds and

6 FAQs about [Battery cabinet factory production process]

How is automation used in battery manufacturing?

As a result, automation is used to integrate complex sub-processes into a unified manufacturing process. The process consists of three phases: electrode manufacturing, cell assembly, and forming, aging, and validation. The initial step in battery manufacturing is the production of two covered layers, the anode and the cathode, called electrodes.

What is a Gigafactory battery manufacturing process?

The battery manufacturing process within a gigafactory is complex. Due to the high production volumes and the colossal size of these factories, various challenges may arise. As a result, automation is used to integrate complex sub-processes into a unified manufacturing process.

What is the final stage in the battery manufacturing process?

The final stage in the battery manufacturing process is forming, aging, and validation. Conditioning is a critical stage in the process, where the cell is charged, discharged, and tested to evaluate its characteristics and performance.

How is a battery made?

The initial step in battery manufacturing is the production of two covered layers, the anode and the cathode, called electrodes. The process uses two identical and separate production lines, one for the anode and another for the cathode, to prevent cross-contamination. Typically, the anode consists of a copper foil coated with graphite.

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

Update Information

- Production process site of energy storage battery cabinet

- New Energy Battery Cabinet Production Process

- Energy storage battery cabinet for factory

- Battery cabinet production companies in Kuwait

- Battery cabinet cold plate production integrated system

- Mauritius Energy Storage Cabinet Battery Factory

- Energy storage cabinet production and processing process

- Fully automatic lithium battery station cabinet production line

- Battery cabinet process step settings

- New Energy Battery Cabinet Process

- Beirut Photovoltaic Energy Storage Cabinet Battery Factory

- Brunei lithium battery energy storage cabinet factory is running

- Conakry battery storage cabinet production

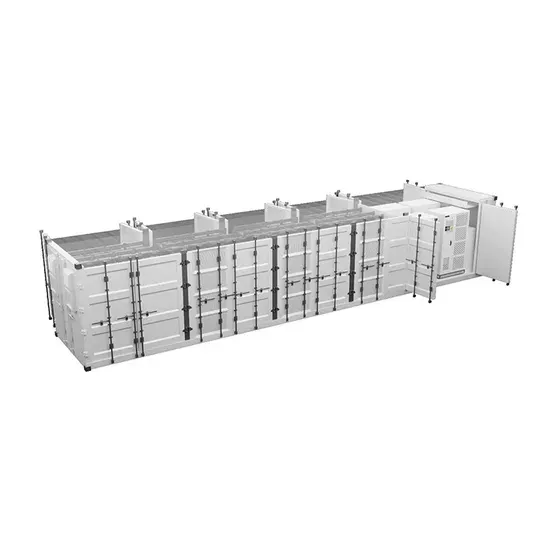

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.