The Rise of New Energy Storage Cabinet Manufacturers:

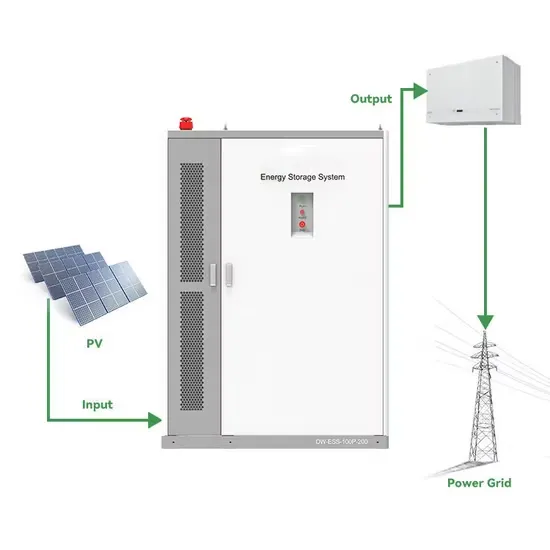

Nov 10, 2020 · Imagine your phone battery, but scaled up to power factories, hospitals, or even entire neighborhoods. That''s essentially what new energy storage cabinet manufacturers are

Energy storage cabinet production and processing

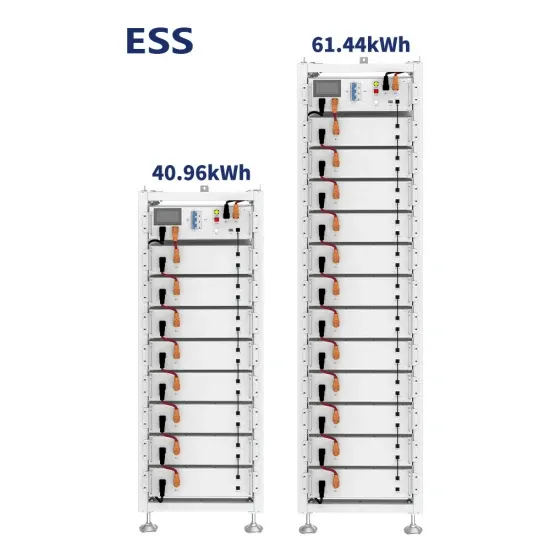

Nov 30, 2022 · Breakthroughs have been made in a variety of energy storage technologies. Lithium-ion batterydevelopment trends continued toward greater capacities and longer

Battery Cabinet Tech: Core Processes & Edge

Energy storage battery cabinet is an important part of the power system. By integrating multiple technical processes, it can provide stable and safe energy management solutions for industry

New energy storage cabinet production enterprise

Breakthroughs have been made in a variety of energy storage technologies. Lithium-ion batterydevelopment trends continued toward greater capacities and longer lifespans. CATL

Energy storage cabinet production process flow chart

tion. Identify new scalabl manufacturing proces nly use renewable energy to power process equipment. This includes generate The operation process chart & flow process chart is

From Raw Materials to Reliable Power: Inside the Energy

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Energy storage battery cabinet production process

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Smart energy storage cabinet production process

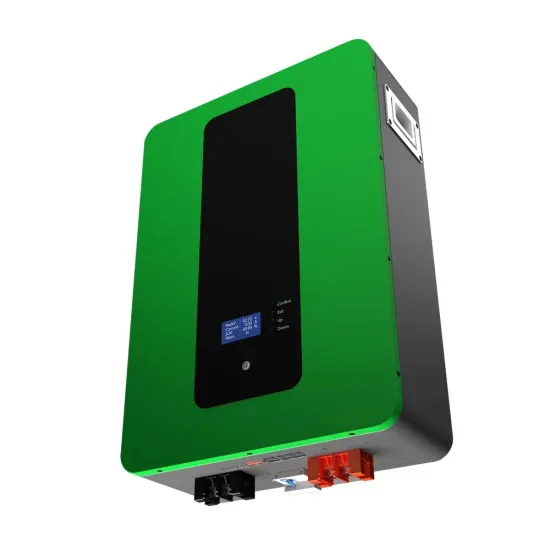

Key Features of Battery Cabinet Systems. High Efficiency and Modularity: Modern battery cabinet systems, such as those from CHAM Battery, offer intelligent liquid cooling to maintain optimal

Battery Cabinet Recycling Process | We Group E-Site

Rethinking the Value Chain As battery-as-a-service models dominate commercial energy storage, recycling isn''t just an endpoint—it''s becoming a revenue stream. ENGIE''s new contracts now

How about new energy storage cabinet | NenPower

Jun 1, 2024 · 1. INNOVATIVE TECHNOLOGY The landscape of energy storage has witnessed a profound transformation, thanks in large part to the advent of new energy storage cabinets.

Battery cabinet production process English

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Narada''s advanced recycling capabilities support a closed-loop battery

Narada''s advanced recycling capabilities support a closed-loop battery ecosystem by recovering valuable materials efficiently and minimizing environmental impact. ♻️🔋 Bipolar membrane

The rise of China''s new energy vehicle lithium-ion battery

Mar 1, 2023 · Empirically, we investigate the developmental process of the new energy vehicle battery (NEVB) industry in China. China has the highest production volume of NEVB

Illustrated explanation of the battery cabinet production

Battery formation (BF) - a critical step in the battery production process > Essential stage every battery needs to undergo in the manufacturing process to become a functional unit > Activation

Environmental life cycle assessment on the recycling processes of power

Jan 10, 2025 · Therefore, improving the power structure and using clean energy sources might effectively mitigate the environmental impact. Our comprehensive study of the power battery

The status quo and future trends of new energy vehicle power batteries

Nov 1, 2022 · At present, as the NEV industry makes the transition and the rapid development of the NEV battery industry, with the expansion of battery production capacity, the products of the

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids. But here''s the

Production planning and process optimization of a cell

Jan 1, 2022 · In the layout of battery cell manufacturing, the formation process is a cost and area intensive process step. Different process parameters significantly influence the machine

Update Information

- New Energy Battery Cabinet Process

- Production process site of energy storage battery cabinet

- Price of new energy battery cabinet

- New Energy Battery Energy Storage Production

- New Energy Battery Cabinet Communication Protocol

- New Energy Battery Cabinet Query

- Why is the battery cabinet not a new energy source

- Vienna New Energy Battery Cabinet

- Conakry New Energy Battery Cabinet Enterprise

- Namibia s new energy battery cabinet manufacturer

- New Energy New Energy Battery Cabinet Replacement

- New Energy Battery Cabinet Communication

- New energy battery cabinet quality issues

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.