Battery cabinets are process materials

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

Battery cabinets are process materials

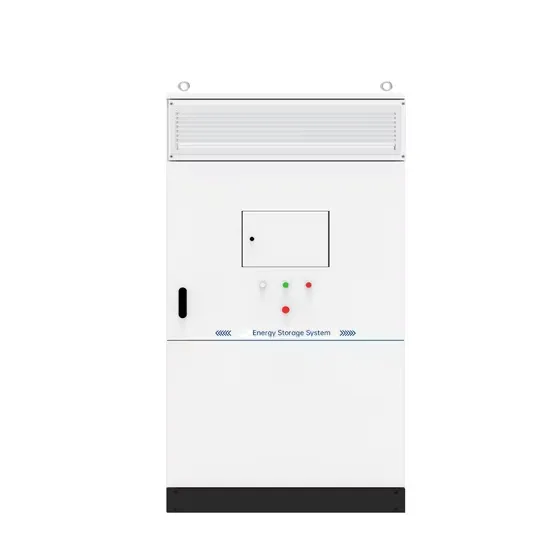

A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the batteryand all its accessories from the external environment. The enclosures come in different

Battery cabinet production process English

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Illustrated explanation of the battery cabinet production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from

Battery Cycle Performance Analysis and BTS Process Step

Sep 12, 2024 · The work step settings shown in the Figure below (Fig. 4) are one of the commonly used test methods for lithium battery cycle performance. The constant current-constant

Battery cabinets are process materials

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Illustrated explanation of the battery cabinet production

What is a battery formation process? s involves the battery''s initial charging and discharging cycles. This step helps form the solid electrolyte interphase (SEI) layer,which is crucial for

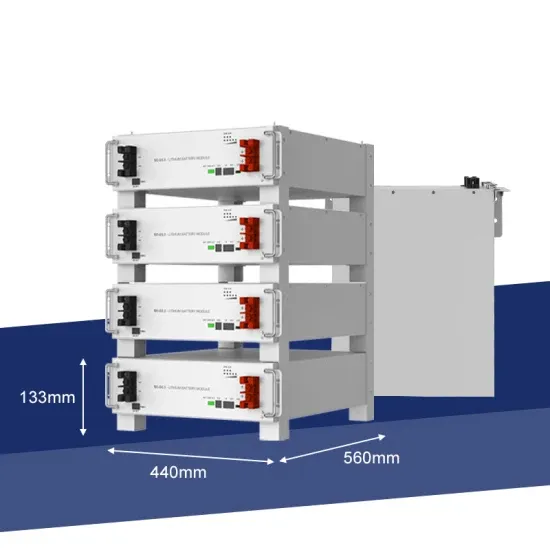

Lithium battery cabinet installation process

L Lithium-Ion Battery Energy Storage System. Designed by data center experts for data center users, the Vertiv(TM) HPL battery cabinet brings you cutting edge lithium-ion battery

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 本文档主要介绍电池柜安装和调试的操作方法。2 Tools / 安装工具 4 Installing a Battery Cabinet / 安装电池柜 PDU8000 Battery Cabinet-T Quick Guide 4.1 Checking Before

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

6 FAQs about [Battery cabinet process step settings]

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

How do you assemble a battery?

The next step is assembling the battery cells. There are two primary methods: Winding: The anode and cathode foils, separated by a porous film, are wound into a jelly-roll configuration. Stacking: Stack the anode, separator, and cathode layers in a flat, layered structure. 4.2 Cell Enclosure

What is a battery formation process?

The formation process involves the battery’s initial charging and discharging cycles. This step helps form the solid electrolyte interphase (SEI) layer, which is crucial for battery stability and longevity. During formation, carefully monitor the battery’s electrochemical properties to meet the required specifications. 6.2 Conditioning

How to test battery cycle life?

Constant current charging and discharging and constant current-constant voltage charging modes are generally used to test battery cycle life. Cycle performance testing can be conducted using charge and discharge equipment (Fig. 1). Fig. 1 CT-4008Q-5V100mA-124 Battery Testing System

Why do batteries need a constant temperature chamber?

To ensure that the battery is in a steady-state environment, constant temperature chambers are often used to create a stable environment to avoid temperature fluctuations that can cause errors, or high and low temperature chambers are used to explore the cycle life of the battery at different temperatures.

How do you prepare an electrolyte for a lithium battery?

The electrolyte facilitates ion movement between the cathode and anode, which is essential for the battery’s operation. Electrolyte preparation involves: Solvent Selection: Choosing a solvent that ensures good ionic conductivity and stability. Salt Dissolution: Dissolving lithium salts (e.g., LiPF6) in the solvent creates the electrolyte solution.

Update Information

- New Energy Battery Cabinet Production Process

- New Energy Battery Cabinet Process

- Lithium battery station cabinet base station energy and process

- The process of replacing lithium batteries in Nauru s outdoor communication battery cabinet

- Battery cabinet factory production process

- Production process site of energy storage battery cabinet

- What does a battery cabinet connected in series look like

- What is the charging temperature of the battery cabinet

- Maldives energy storage counter custom battery cabinet

- San Salvador outdoor communication battery cabinet battery replacement price

- How to calculate the storage time of battery cabinet

- Kathmandu outdoor communication battery cabinet quotation and base station

- Energy storage cabinet manufacturing industrial battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.