Programme Agreement Signed with Reliance New Energy Battery

Feb 18, 2025 · This agreement awards Reliance New Energy Battery Limited a 10 GWh ACC capacity, following a competitive global tender process and makes it eligible to receive

New Energy Batteries to Solar Energy Storage: Powering the

Jan 5, 2025 · If you''re a homeowner with solar panels, an eco-entrepreneur, or just someone tired of sky-high electricity bills, this article''s your backstage pass to understanding how new energy

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Battery Cabinet Recycling Process | We Group E-Site

Rethinking the Value Chain As battery-as-a-service models dominate commercial energy storage, recycling isn''t just an endpoint—it''s becoming a revenue stream. ENGIE''s new contracts now

Liquid Cooling: Efficiency in Battery Storage

The solution to this challenge is the advanced Liquid Cooling Battery Cabinet, a technology designed to provide precise and uniform temperature control, ensuring optimal performance

How did the new energy battery cabinet come from

Will battery energy storage save a lot of carbon? In 2023, battery energy storage systems in Great Britain saved 950,000 tonnes of carbon emissions. This year they are on track to increase this

Accuracy requirements for battery aging cabinets in battery

Jun 30, 2025 · The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

What are the energy storage cabinet processing technologies?

Sep 20, 2024 · Energy storage cabinet processing technologies involve several advanced methods for efficiently storing and managing electrical energy, including 1. lithium-ion battery

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Understanding Battery Storage Cabinet Components and Benefits Key Components of a Battery Storage System A battery storage system is a sophisticated unit

Why Energy Storage New Energy Batteries Are the Game

Jul 12, 2023 · Imagine this: A Texas heatwave hits, but your solar-powered home keeps humming along smoothly thanks to a sleek battery system that laughs in the face of power outages. This

The Rise of New Energy Storage Cabinet Manufacturers:

Nov 10, 2020 · Imagine your phone battery, but scaled up to power factories, hospitals, or even entire neighborhoods. That''s essentially what new energy storage cabinet manufacturers are

New energy battery cabinet assembly process diagram

Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services and industrial and commercial

The Rise of New Energy Storage Cabinet Manufacturers:

Nov 10, 2020 · Who''s Searching for Energy Storage Cabinets and Why? Imagine your phone battery, but scaled up to power factories, hospitals, or even entire neighborhoods. That''s

Xiaoyi New Energy Battery Energy Storage Cabinet

Aug 21, 2021 · Good conductivity, made of high-quality pure copper, nickel-plated process, conductive, wear-resistant. Scope of application: new energy lithium battery energy storage

Battery cabinets are process materials

The battery cabinet for base station is a special cabinet to provide uninterrupted power supply for communication base stations and related equipment, which can be placed with various types

How to design an energy storage cabinet: integration and

Jan 3, 2025 · The design of an energy storage cabinet usually follows the following steps: Demand analysis: Determine basic parameters such as energy storage capacity, load

Battery cabinets are process materials

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids. But here''s the

Energy storage cabinet production and processing

Nov 30, 2022 · Energy storage cabinet processing technologies involve several advanced methods for efficiently storing and managing electrical energy, including 1. lithium-ion battery

shared power exchange cabinet

Mar 22, 2020 · What is a smart switchboard? Smart switchboard is also called shared switchboard, shared battery cabinet, takeaway switchboard, etc. As the name suggests, it is a

Battery Cabinet Tech: Core Processes & Edge

With the transformation of energy structure and the increasing demand for intelligent power system, Energy Storage Battery cabinets have become important infrastructure in industrial

3 FAQs about [New Energy Battery Cabinet Process]

What is energy storage cabinet?

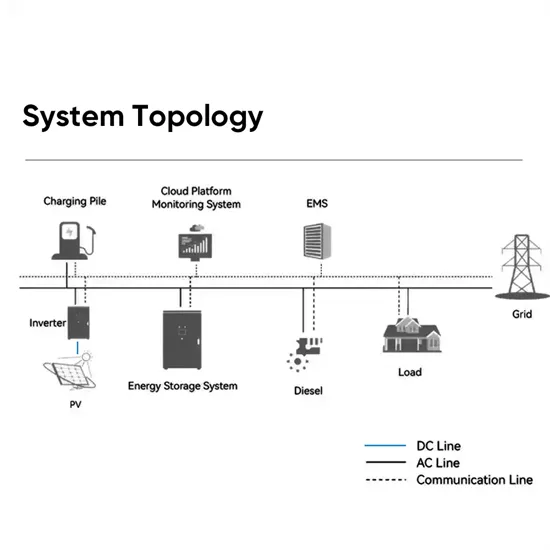

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

Why do energy storage cabinets use STS?

STS can complete power switching within milliseconds to ensure the continuity and reliability of power supply. In the design of energy storage cabinets, STS is usually used in the following scenarios: Power switching: When the power grid loses power or fails, quickly switch to the energy storage system to provide power.

Update Information

- New Energy Battery Cabinet Process

- New energy battery cabinet base station power generation equipment

- Belgrade Customized New Energy Battery Cabinet

- New energy single battery cabinet price

- Recommendation of lithium battery energy storage cabinet for charging pile in New Delhi

- New Energy Battery Cabinet Cooling Method

- Lithium battery station cabinet base station energy and process

- Multi-connector for Accra new energy battery cabinet

- New Energy Battery Cabinet Heat Conductivity

- New Energy Battery Cabinet Base Station Power Structure

- How to measure the electricity of new energy battery cabinet

- Is there a problem with the new energy original battery cabinet

- New energy battery cabinet quality issues

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.