Graphite | Critical Materials Monitor – Columbia University

Graphite is used as the anode material in a lithium-ion battery. The graphite found in the anode can be either natural graphite or synthetic graphite. The United States Geological Survey

Natural graphite anode for advanced lithium-ion Batteries:

Jan 1, 2025 · Natural graphite (NG) is widely used as an anode material for lithium-ion batteries (LIBs) owing to its high theoretical capacity (∼372 mAh/g), low li

Lithium-ion Battery Grade Graphite Market

Feb 9, 2025 · Recent export controls on graphite products—implemented in December 2023—directly disrupted anode material supplies for lithium-ion batteries. This compels

Practical application of graphite in lithium-ion batteries

Sep 20, 2024 · Environmentally-friendly oxygen-free roasting/wet magnetic separation technology for in situ recycling cobalt, lithium carbonate and graphite from spent LiCoO2/graphite lithium

Top 10 Companies in the Natural Graphite for Lithium

Jun 9, 2025 · 10. Ashbury Graphite Mills Headquarters: Columbia Station, Ohio, USA Key Offering: Purified natural graphite, coated spherical graphite Ashbury Graphite Mills

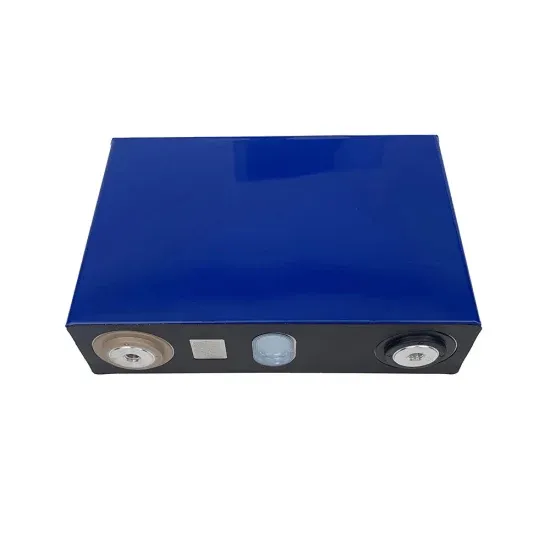

LITHIUM-ION BATTERY

Oct 9, 2024 · The ternary lithium battery adopts NCM (523) coating series, and the negative electrode adopts secondary particle artificial graphite, which has excellent cycle performance

Manufacturing energy analysis of lithium ion battery pack

Jan 1, 2017 · Lithium ion batteries (LIB) are widely used to power electric vehicles. Here we report a comprehensive manufacturing energy analysis of the popular LMO-graphite LIB pack used

Why EV battery makers are grappling with graphite

Jul 28, 2022 · EV Battery Makers Are Grappling with Graphite Graphite is used for the negative end of a lithium-ion battery, known as the anode. Currently, 85% of graphite comes from

Colombia energy density lithium ion battery

Separator‐Supported Electrode Configuration for Ultra‐High Energy The fact that the initial lithium-ion battery with an energy density under 100 Wh kg −1 had been developed to one with

Progress, challenge and perspective of graphite-based

Mar 15, 2024 · The anode material is not the bottleneck of battery energy density, because the specific capacity of lithium manganate, lithium iron phosphate, lithium cobaltate and other

Fast-charging capability of graphite-based lithium-ion

Oct 30, 2023 · Li + desolvation in electrolytes and diffusion at the solid–electrolyte interphase (SEI) are two determining steps that restrict the fast charging of graphite-based lithium-ion

The state of understanding of the lithium-ion-battery graphite

Aug 1, 2016 · An in-depth historical and current review is presented on the science of lithium-ion battery (LIB) solid electrolyte interphase (SEI) formation on the

Colombia energy density lithium ion battery

Which lithium ion battery has the highest energy density? At present,the publicly reported highest energy density of lithium-ion batteries (lithium-ion batteries in the traditional sense) based on

Lithium Battery Pack for Low Speed Electric Vehicles Market

Feb 6, 2025 · What factors are driving the adoption of lithium battery packs over traditional lead-acid batteries in low-speed electric vehicles? The shift toward lithium battery packs in low

Perspective on fast-charging lithium-ion batteries:

The report begins with a discussion of lithium battery transport bottlenecks in fast charging, which induces lithium plating on graphite anodes. Next, the review summarizes state-of-the-art

Battery Cells and Future Battery Cell Chemistries | HORIBA Battery

1. Introduction Lithium-ion (Li-ion) battery cells are widely used in various industries such as automotive, consumer electronics, and stationary storage, leading to the development of

Thermal management of Lithium-ion battery pack through the application

Jan 25, 2021 · Thermal management of Lithium-ion battery pack through the application of flexible form-stable composite phase change materials

Lithium‐based batteries, history, current status,

Oct 7, 2023 · The operational principle of the rechargeable battery is centered on a reversible redox reaction taking place between the cathode (positive

Enhancing lithium-ion battery pack safety: Mitigating

Jul 1, 2024 · Enhancing lithium-ion battery pack safety: Mitigating thermal runaway with high-energy storage inorganic hydrated salt/expanded graphite composite

Enhancing lithium-ion battery pack safety: Mitigating

Jul 1, 2024 · In this study, we propose an inorganic hydrated salt/expanded graphite composite (TCM40/EG) that integrates phase change and thermochemical heat storage for thermal

TOP LITHIUM ION BATTERY SUPPLIERS IN COLOMBIA

A battery is a modified lithium-ion battery that uses lithium-titanate nanocrystals, instead of, on the surface of its . This gives the anode a surface area of about 100 square meters per gram,

LITHIUM-ION BATTERY

Apr 14, 2025 · The ternary lithium battery adopts NCM (523) coating series, and the negative electrode adopts secondary particle artificial graphite, which has excellent cycle performance

Lithium Batteries in Colombia: Energy Revolution Ahead?

Colombia must act decisively to avoid becoming a lithium spectator in the global energy transition. With strategic partnerships and ecological safeguards, lithium batteries could truly electrify its

Battery pack price increases at different battery-grade graphite

Aug 14, 2025 · Battery pack price increases at different battery-grade graphite price levels - Chart and data by the International Energy Agency.

Update Information

- Production of lithium battery pack types

- Sucre 40a lithium battery pack

- Lithium battery pack safety design

- Tirana 21700 lithium battery pack manufacturer

- Which battery cell is better for Roman lithium battery pack

- Lithium battery pack large company

- N Djamena lithium iron phosphate battery pack

- Which lithium battery pack has the best price

- Türkiye pack lithium battery

- Lithium battery pack error

- Masai 220V lithium battery pack

- What do the lithium battery pack labels mean

- Allowable range of capacity difference of Honiara lithium battery pack

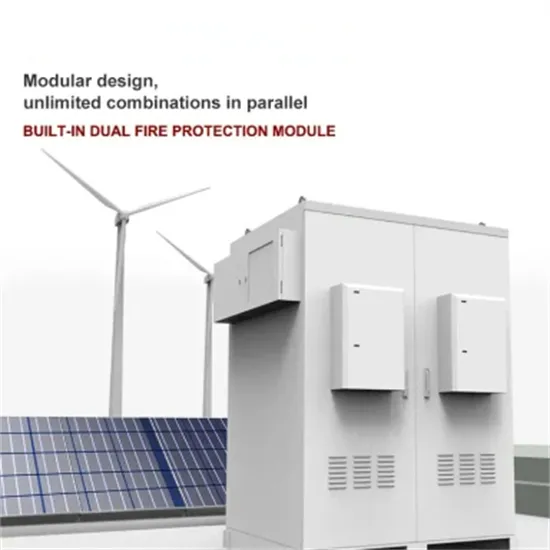

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.