Liquid flow energy storage, targeted by Huawei, has

Zhang Feng said that Huawei has been paying close attention to the development of the liquid flow battery industry. In October 2022, the world''s largest power and capacity 100-megawatt

The Effect of Electrolyte Composition on the Performance of

Dec 24, 2023 · Flow batteries are promising for large-scale energy storage in intermittent renewable energy technologies. While the iron–chromium redox flow battery (ICRFB) is a low

What Type of Battery Does My Huawei Phone Use?

Apr 11, 2025 · Huawei phones primarily use lithium-ion (Li-ion) or lithium-polymer (Li-Po) batteries, depending on the model. These batteries are chosen for their high energy density,

Study on the Influence of the Flow Factor on the

Mar 24, 2025 · There are many types of energy storage systems. Among them, one of the most interesting in the last decades has been vanadium redox flow batteries (VRFBs) because of

Liquid flow energy storage, targeted by Huawei, has

In October 2022, the world''s largest power and capacity 100-megawatt liquid flow battery energy storage peak-shaving power station was officially connected to the grid in Liaoning.

Huawei files patent for a new solid-state battery

Nov 6, 2024 · Huawei''s new patent on sulfide solid-state batteries addresses liquid battery degradation, promising high energy density, safety, long life, and

Battery Module Storage Requirements

Jun 23, 2025 · The warehouse keeper shall collect battery storage information every month and periodically report the battery inventory information. The batteries in long-term storage shall be

How Do Huawei Batteries Compare to Those from Other

Apr 11, 2025 · When it comes to smartphones, the battery is one of the most critical components that can significantly affect performance and user experience. Huawei, a leading player in the

Adjustment of Electrolyte Composition for All-Vanadium

Oct 16, 2023 · Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and

New Flow Battery Chemistries for Long Duration Energy

Sep 27, 2024 · Abstract: Flow batteries, with their low environmental impact, inherent scalability and extended cycle life, are a key technology toward long duration energy storage, but their

Understanding Battery Energy Storage System

Jan 16, 2023 · Flow battery technology has lower round-trip efficiency compared to Lithium-ion batteries. It means that higher energy is wasted (during charge

SECTION 5: FLOW BATTERIES

Jun 14, 2022 · Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions . external to the battery cell. Electrolytes are pumped. through

Practical flow battery diagnostics enabled by chemically

Jul 10, 2025 · Currently, all methods for monitoring flow battery performance are based on simple sensors that take bulk electrical, flow, and liquid-level readouts, allowing them to function

Huawei iron liquid flow battery composition

In this study, a green Eu-Ce acidic aqueous liquid flow battery with high voltage and non-toxic characteristics is reported. The Eu-Ce RFB has an ultrahigh single cell voltage of 1.96 V.

6 FAQs about [Huawei flow battery composition]

What are the components of a flow battery?

Flow batteries comprise two components: Electrochemical cell Conversion between chemical and electrical energy External electrolyte storage tanks Energy storage Source: EPRI K. Webb ESE 471 5 Flow Battery Electrochemical Cell Electrochemical cell Two half-cellsseparated by a proton-exchange membrane(PEM)

How do flow batteries work?

K. Webb ESE 471 3 Flow Batteries Flow batteries are electrochemical cells, in which the reacting substances are stored in electrolyte solutions external to the battery cell Electrolytes are pumped through the cells Electrolytes flow across the electrodes Reactions occur atthe electrodes Electrodes do not undergo a physical change Source: EPRI

What are the different types of flow batteries?

There are different types of flow batteries and they are the following: redox flow batteries, hybrid flow batteries, and fewer batteries for membrane. The costlier one is the membrane flow battery and their battery parts are very brittle and can be easily corroded by the reactants of the operation.

Can flow batteries be used as a fuel cell?

Flow batteries can be employed both as a rechargeable secondary battery and a fuel cell. The earlier loaded electrolyte will be the alternative for the discharged electrolyte and thus it has the synergic significance.

Do flow batteries need a fluid model?

Flow batteries require electrolyte to be pumped through the cell stack Pumps require power Pump power affects efficiency Need a fluid model for the battery in order to understand how mechanical losses affect efficiency K. Webb ESE 471 29 RFB Fluid Model Power required to pump electrolyte through cell stack Pumping power is proportional to

What determines the energy storage capacity of a flow battery?

Volume of electrolyte in external tanks determines energy storage capacity Flow batteries can be tailored for an particular application Very fast response times- < 1 msec Time to switch between full-power charge and full-power discharge Typically limited by controls and power electronics Potentially very long discharge times

Update Information

- Huawei Bangji Flow Battery

- Huawei Sri Lanka all-vanadium liquid flow battery

- Rocking Chair Battery Flow Battery

- Vientiane Electric Power Construction Zinc-Iron Liquid Flow Battery

- The first application of flow battery

- Huawei energy storage battery trade in Guatemala

- Leading enterprise of vanadium liquid flow energy storage battery

- All-vanadium redox flow battery components

- Advantages and disadvantages of Huawei s energy storage battery

- Power Battery Iron and Chromium Flow Batteries

- Huawei Energy Storage Battery

- Middle East zinc-bromine flow energy storage battery

- Huawei cylindrical lithium battery model

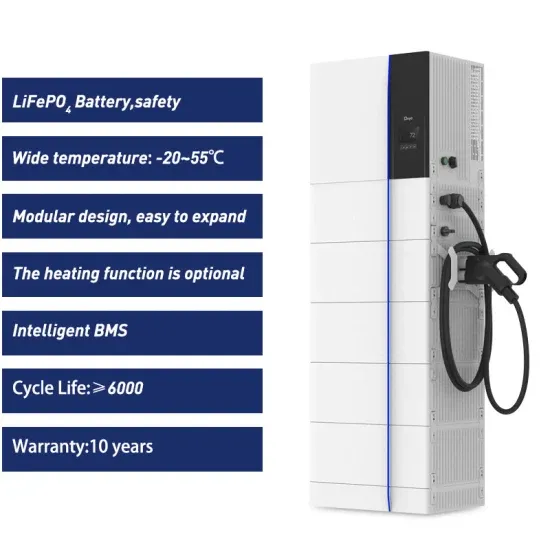

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.