Advancing Flow Batteries: High Energy Density

Dec 17, 2024 · A high-capacity-density (635.1 mAh g − ¹) aqueous flow battery with ultrafast charging (<5 mins) is achieved through room-temperature liquid

All vanadium liquid flow energy storage enters the GWh era!

Jun 19, 2025 · On the afternoon of October 30th, the world''s largest and most powerful all vanadium flow battery energy storage and peak shaving power station (100MW/400MWh) was

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Technology Strategy Assessment

Jan 12, 2023 · Background Introduction Redox flow batteries (RFBs) or flow batteries (FBs)—the two names are interchangeable in most cases—are an innovative technology that offers a

Huawei Digital Energy visits Beijing Puneng to exchange ideas on all

Mr. Ge from Beijing Puneng focused on the company''s R&D technology, vanadium battery industry chain layout and project promotion and application. Al l-vanadium liquid flow battery is

Sri lanka electric all-vanadium liquid flow battery energy

It is discovered that the open-circuit voltage variation of an all-vanadium liquid flow battery is different from that of a nonliquid flow energy storage battery, which primarily consists of four

Technology Strategy Assessment

Jan 12, 2023 · Redox flow batteries (RFBs) or flow batteries (FBs)—the two names are interchangeable in most cases—are an innovative technology that offers a bidirectional energy

sri lanka electric all-vanadium liquid flow battery energy

A vanadium-chromium redox flow battery toward sustainable energy storage Huo et al. demonstrate a vanadium-chromium redox flow battery that combines the merits of all

What is all-vanadium liquid flow battery energy storage?

Feb 11, 2024 · What is all-vanadium liquid flow battery energy storage? 1. All-vanadium liquid flow batteries utilize a unique electrochemical process for energy storage, specifically leveraging

Towards a high efficiency and low-cost aqueous redox flow battery

May 1, 2024 · The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow batteries,

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Vanadium batteries are mainly composed of electrolyte, electrodes, selective proton exchange membranes, bipolar plates and fluid collectors. Among them, the electrolyte

Sichuan V-LiQuid Energy Co., Ltd.

V-Liquid is a developer and manufacturer specializing in all-vanadium flow battery technology. We focus on the research, development, production, and sales of core materials, electric stacks,

Long term performance evaluation of a commercial vanadium flow battery

Jun 15, 2024 · This demonstrates the advantage that the flow batteries employing vanadium chemistry have a very long cycle life. Furthermore, electrochemical impedance spectroscopy

Liquid flow batteries are rapidly penetrating into hybrid

Oct 12, 2024 · In addition to vanadium flow batteries, projects such as lithium batteries + iron-chromium flow batteries, and zinc-bromine flow batteries + lithium iron phosphate energy

Sri lanka electric all-vanadium liquid flow battery energy

The liquid electrolyte is the single most important materialfor making vanadium flow batteries,a leading contender for providing several hours of storage cost-effectively. Samantha McGahan

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Flow batteries have a storied history that dates back to the 1970s when researchers began experimenting with liquid-based energy storage solutions. The

All-vanadium Liquid Flow Battery

With all-vanadium liquid flow batteries, it can achieve the mutual conversion of electrical energy and chemical energy to meet the needs of electrical energy storage. The system operates at

Vanadium Redox Flow Batteries

Jul 30, 2023 · Vanadium Redox Flow Batteries: Technology Considerations Flow batteries are generally defined as batteries that transform the electron flow from activated electrolyte into

All-soluble all-iron aqueous redox flow batteries: Towards

Feb 1, 2025 · All-iron aqueous redox flow batteries (AI-ARFBs) are attractive for large-scale energy storage due to their low cost, abundant raw materials, and the safety and

5 FAQs about [Huawei Sri Lanka all-vanadium liquid flow battery]

When were vanadium flow batteries invented?

In the 1980s, the University of New South Wales in Australia started to develop vanadium flow batteries (VFBs). Soon after, Zn-based RFBs were widely reported to be in use due to the high adaptability of Zn-metal anodes to aqueous systems, with Zn/Br2 systems being among the first to be reported.

How long do flow batteries last?

Valuation of Long-Duration Storage: Flow batteries are ideally suited for longer duration (8+ hours) applications; however, existing wholesale electricity market rules assign minimal incremental value to longer durations.

What is a Technology Strategy assessment on flow batteries?

This technology strategy assessment on flow batteries, released as part of the Long-Duration Storage Shot, contains the findings from the Storage Innovations (SI) 2030 strategic initiative.

Why do flow battery developers need a longer duration system?

Flow battery developers must balance meeting current market needs while trying to develop longer duration systems because most of their income will come from the shorter discharge durations. Currently, adding additional energy capacity just adds to the cost of the system.

Who invented the flow battery system?

The principle of the flow battery system was first proposed by L. H. Thaller of the National Aeronautics and Space Administration in 1974, focusing on the Fe/Cr system until 1984.

Update Information

- Characteristics of all-vanadium liquid flow battery

- Marshall Islands UET All-Vanadium Liquid Flow Battery

- New all-vanadium liquid flow battery

- Liquid flow energy storage battery configuration

- Thailand liquid flow battery materialization

- Liquid Flow Battery Company

- All-vanadium redox flow battery components

- Lifespan of all-vanadium liquid flow batteries

- Vanadium Liquid Flow Battery Metal Research Institute

- 1000 degree vanadium liquid flow battery

- Small vanadium liquid flow battery

- What is vanadium liquid flow battery

- Iron-vanadium liquid flow battery cost

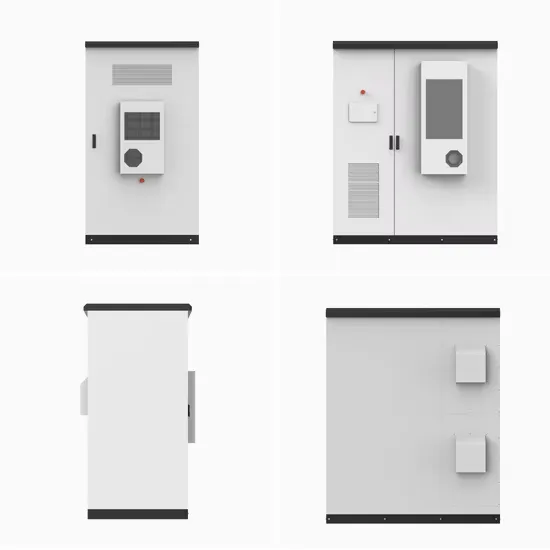

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.