A review of bipolar plate materials and flow field designs in the all

Apr 1, 2022 · A bipolar plate (BP) is an essential and multifunctional component of the all-vanadium redox flow battery (VRFB). BP facilitates several functions in

All-vanadium redox flow batteries

Jan 1, 2025 · The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Flow battery production: Materials selection and

Oct 1, 2020 · For example, harmonization of the battery system boundary led to freshwater eutrophication and freshwater ecotoxicity values for vanadium redox flow batteries lower than

Constant-Power Characterization of a 5 kW Vanadium

Feb 27, 2022 · Almost all the studies are based on the constant current cycling of flow batteries. In the present work, we explore a different perspective of a flow battery and characterize the

Insights into all-vanadium redox flow battery: A case study

Mar 20, 2018 · This work reports a systematic assessment of operating conditions (charge/discharge current density and electrolyte flow rate) and battery components (electrode

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Abstract Battery storage systems become increasingly more important to fulfil large demands in peaks of energy consumption due to the increasing supply of intermittent

Review—Preparation and modification of all-vanadium redox flow battery

Nov 21, 2024 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Vanadium Redox Flow Batteries: Electrochemical

Apr 3, 2019 · This chapter covers the basic principles of vanadium redox flow batteries, component technologies, flow configurations, operation strategies,

An Open Model of All-Vanadium Redox Flow Battery Based

Oct 19, 2021 · Based on the component composition and working principle of the all-vanadium redox flow battery (VRB), this paper looks for the specific influence mechanism of the

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · Compared with the all-vanadium flow battery, since the vanadium/air single flow battery uses an air/oxygen diffusion electrode to replace the flow positive half-cell, the amount

Development of the all‐vanadium redox flow battery for

May 24, 2011 · The commercial development and current economic incentives associated with energy storage using redox flow batteries (RFBs) are summarised. The analysis is focused on

Vanadium Redox Flow Battery

3 days ago · Vanadium redox flow batteries also known simply as Vanadium Redox Batteries (VRB) are secondary (i.e. rechargeable) batteries. VRB are applicable at grid scale and local

Attributes and performance analysis of all-vanadium redox flow battery

May 17, 2023 · Vanadium redox flow batteries (VRFBs) are the best choice for large-scale stationary energy storage because of its unique energy storage advantages. However, low

Design and development of large-scale vanadium redox flow batteries

Jan 30, 2024 · Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power and capacity

A comprehensive modelling study of all vanadium redox flow battery

Aug 30, 2023 · To investigate the combined effects of electrode structural parameters and surface properties on the vanadium redox flow battery (VRFB) performance, a

Redox Flow Batteries: Materials, Design and

Sep 8, 2021 · When this is the case, the defining component of the battery is the electrolyte, e.g., a battery with vanadium electrolyte on both tanks is an all

Review—Bipolar Plates for the Vanadium Redox

Jun 2, 2021 · Bipolar plates are one of the key components of vanadium redox flow batteries. They electrically conduct and physically separate adjacent cells

6 FAQs about [All-vanadium redox flow battery components]

Are vanadium redox flow batteries viable?

Among these systems, vanadium redox flow batteries (VRFB) have garnered considerable attention due to their promising prospects for widespread utilization. The performance and economic viability of VRFB largely depend on their critical components, including membranes, electrodes, and electrolytes.

What are vanadium redox flow batteries (VRB)?

Vanadium redox flow batteries also known simply as Vanadium Redox Batteries (VRB) are secondary (i.e. rechargeable) batteries. VRB are applicable at grid scale and local user level. Focus is here on grid scale applications. VRB are the most common flow batteries.

Which chemistry is best for redox flow batteries?

The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it utilizes four stable redox states of vanadium. This chapter reviews the state of the art, challenges, and future outlook for all-vanadium redox flow batteries. 1.

What are the parts of a vanadium redox flow battery?

The vanadium redox flow battery is mainly composed of four parts: storage tank, pump, electrolyte and stack. The stack is composed of multiple single cells connected in series. The single cells are separated by bipolar plates.

Are redox flow batteries a viable alternative to lithium-ion batteries?

Redox flow batteries (RFBs) are emerging as promising alternatives to lithium-ion batteries to meet this growing demand. As end-users, RFB operators must characterise the batteries to learn more about the battery's behaviour and performance and better integrate such RFB technology into energy systems.

What is a redox flow battery (VRFB)?

As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial component utilized in VRFB, has been a research hotspot due to its low-cost preparation technology and performance optimization methods.

Update Information

- Estonian all-vanadium liquid flow battery electrolyte

- El Salvador s new all-vanadium flow battery electrolyte pump

- Vanadium Redox Flow Battery Purchase

- Marshall Islands UET All-Vanadium Liquid Flow Battery

- Togo All-vanadium Liquid Flow Battery

- All-vanadium liquid flow energy storage battery project

- Characteristics of all-vanadium liquid flow battery

- Battery cabinet current flow direction base station

- Liquid flow battery storage efficiency

- What does the flow battery for communication base stations do

- South Korea communication base station flow battery lightning protection

- Flow battery construction area

- Vanadium liquid flow battery effect

Solar Storage Container Market Growth

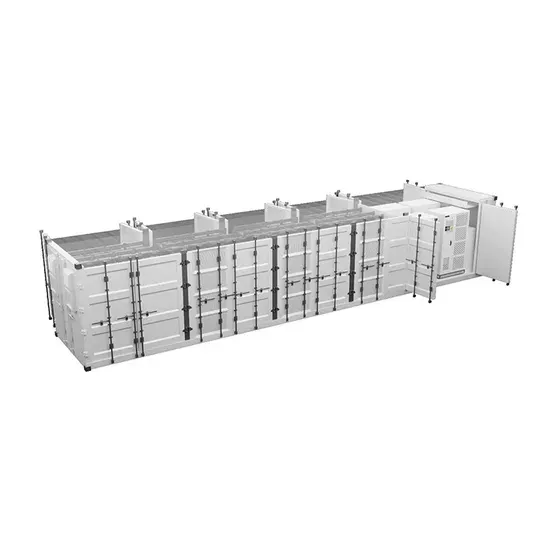

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.