Optimization of the Heat Dissipation Structure for Lithium-Ion Battery

Apr 22, 2022 · The battery thermal management system plays an important role in electric vehicles, and determines the performance and the lifespan of electric vehicles. In this paper,

Thermal management for the prismatic lithium-ion battery pack

Dec 15, 2024 · As a result, the disturbance in the upper portion of the battery pack was more intense, i.e., it corresponds to a stronger heat dissipation flux, which further reduces the heat

Thermal characteristics and reliability analysis of liquid-cooled heat

Jun 15, 2025 · For a long time, many scholars have been devoted to the research of the most advanced battery thermal management system (BTMS), and the current main heat dissipation

of Heat Dissipation of Lithium Battery Pack on Eddy

Dec 3, 2023 · Analysis of Heat Dissipation of Lithium Battery Pack Based on Eddy Current Tube Shuangliang Li, Tao Jing*, Changpeng Li, Xue Han, Ye Hua, Zhang Teng

Effects analysis on heat dissipation characteristics of lithium-ion

Jan 1, 2022 · Effects analysis on heat dissipation characteristics of lithium-ion battery thermal management system under the synergism of phase change material and liquid cooling method

Optimization of liquid cooling and heat dissipation system of lithium

Aug 1, 2021 · A stable and efficient cooling and heat dissipation system of lithium battery pack is very important for electric vehicles. The temperature uniformity design of the battery packs has

Review on Lithium-Ion Battery Heat Dissipation

Jan 29, 2025 · Lithium-ion battery heat dissipation difficulties seriously affect the efficient and stable operation of electronic devices and electric vehicles. Faced

Comprehensive Analysis of Thermal Dissipation in Lithium-

Feb 12, 2025 · ABSTRACT e compact designs and varying airflow conditions present unique challenges. This study investigates the thermal performance of a 16-cell lithium-ion battery

Development and optimization of hybrid heat dissipation

Oct 1, 2024 · Experiments investigated thermal properties, phase change phenomena, and optimal concentrations of nanocarbon inclusions. This study presents the development and

Research on liquid cooling and heat dissipation of lithium-ion battery

Abstract: Based on the heat production characteristics of square lithium-ion batteries, a sort of bionic wing vein channel cool plate was developed. Based on numerical heat transfer theory, a

Effect analysis on heat dissipation performance

Jul 1, 2021 · A heat pipe (HP) heat dissipation model of a lithium-ion-battery pack is established for the climate in the central and southern regions in China, and the heat transfer effects of

Design and research of heat dissipation system of electric

Jun 27, 2024 · The heat dissipation system plays a crucial role in the lithium-ion battery pack of electric vehicles, and its working principle is mainly to effectively dissipate the heat generated

Calculation methods of heat produced by a

Dec 1, 2018 · Lithium‐ion batteries generate considerable amounts of heat under the condition of charging‐discharging cycles. This paper presents quantitative

Analysis of Heat Dissipation of Lithium Battery

Oct 29, 2023 · Abstract and Figures In this study, numerical heat dissipation simulation is carried out using vortex tube heat dissipation technique for the

Study on liquid cooling heat dissipation of Li-ion battery pack

Sep 15, 2023 · According to the heat generation characteristics of lithium-ion battery, the bionic spider web channel is innovatively designed and a liquid-cooled he

Comprehensive Analysis of Thermal Dissipation in Lithium-Ion Battery

Feb 11, 2025 · This study investigates the thermal performance of a 16-cell lithium-ion battery pack by optimizing cooling airflow configurations and integrating phase change materials

Heat dissipation analysis and optimization of lithium-ion

Jun 15, 2022 · However, the cooling capacity is limited by low heat transfer coefficient of air [8]. Park et al [12]. employed forced-air cooling in a rectangular battery pack. The result indicated

Numerical study on heat dissipation performance of a lithium

Aug 30, 2023 · The simulation model is validated by the experimental data of a single adiabatic bare battery in the literature, and the current battery thermal management system based on

Analysis and optimization control of finned heat

Jan 1, 2020 · Then, the orthogonal experiment determines the optimal heat dissipation scheme of the lithium battery pack the air inlet speed is 8 m/s, the

Heat dissipation analysis and multi-objective optimization of

An efficient battery pack-level thermal management system was crucial to ensuring the safe driving of electric vehicles. To address the challenges posed by insufficient heat dissipation in

Thermal management of lithium-ion battery packs in electric

A 3-D model of a 36-cell lithium-ion battery pack was developed and simulated in COMSOL Multiphysics, and the system''s thermal performance was evaluated under various conditions,

Design and research of heat dissipation system

Jun 27, 2024 · This research focuses on the design of heat dissipation system for lithium-ion battery packs of electric vehicles, and adopts artificial intelligence

A review on thermal management of battery packs for

Feb 1, 2024 · This loop is used when the heat exchange between the cells and the environment satisfies the heat dissipation of the battery pack. This happens when the thermostat measures

Study on the thermal interaction and heat dissipation of

Dec 1, 2017 · Because the distance among battery cells is only a few millimeters, the thermal status of battery would directly influent the current efficiency and battery life. In order to

Review on the heat dissipation performance of battery pack

Jan 1, 2014 · This paper reviews the heat dissipation performance of battery pack with different structures (including: longitudinal battery pack, horizontal battery pack, and changing the

Research on the heat dissipation performances of

Feb 15, 2025 · To optimize lithium-ion battery pack performance, it is imperative to maintain temperatures within an appropriate range, achievable through an efective cooling system. This

LFP Battery Pack Combined Heat Dissipation Strategy

Apr 28, 2024 · During the high-power charging and discharging process, the heat generated by the energy storage battery increases significantly, causing the battery temperature to rise

Heat dissipation analysis and multi-objective

Dec 5, 2024 · This study proposes three distinct channel liquid cooling systems for square battery modules, and compares and analyzes their heat dissipation

Modeling and Optimization of Air Cooling Heat Dissipation of Lithium

May 10, 2022 · In this chapter, battery packs are taken as the research objects. Based on the theory of fluid mechanics and heat transfer, the coupling model of thermal field and flow field of

STUDY OF THERMAL CHARACTERISTICS OF LITHIUM

May 17, 2024 · When assessing lithium-ion battery systems'' capacity for heat dissipation, key evaluation indicators include maximum and average temperature of battery pack and

Simulation study on the heat dissipation system of lithium-ion battery

Nov 10, 2024 · With the promotion of "green mobility" and "carbon peak" policies, electric vehicles and their core components, lithium-ion batteries, have attracted much atten

6 FAQs about [Lithium battery pack heat dissipation]

How to optimize the cooling and heat dissipation system of lithium battery pack?

For the optimization of the cooling and heat dissipation system of the lithium battery pack, an improved optimization framework based on adaptive ensemble of surrogate models and swarm optimization algorithm (AESMPSO) is proposed. PSO algorithm can effectively avoid the optimization process from falling into local optimality and premature.

What factors affect the cooling and heat dissipation system of lithium battery?

Based on the previous screening of the factors affecting the cooling and heat dissipation system of the lithium battery pack, four factors are selected: cooling plate thickness m1 (mm), cooling wall thickness m2 (mm), inlet coolant temperature T (K) and velocity of inlet coolant v (m/s).

What is the corresponding design variable for lithium battery cooling & heat dissipation?

The research of X.H. Hao et al. shows that the coolant temperature within a certain temperature range has a certain influence on the cooling effect of the lithium battery cooling and heat dissipation system, so the inlet coolant temperature T (K) is set as the corresponding design variable.

What are the different types of heat dissipation methods for battery packs?

Currently, the heat dissipation methods for battery packs include air cooling , liquid cooling , phase change material cooling , heat pipe cooling , and popular coupling cooling . Among these methods, due to its high efficiency and low cost, liquid cooling was widely used by most enterprises.

Can nano-carbon-based phase change materials improve heat dissipation in a 16-cell lithium-ion battery pack?

This study presents a comprehensive thermal analysis of a 16-cell lithium-ion battery pack by exploring seven geometric configurations under airflow speeds ranging from 0 to 15 m/s and integrating nano-carbon-based phase change materials (PCMs) to enhance heat dissipation.

Does a liquid cooling system improve battery heat dissipation efficiency?

The maximum difference in Tmax between different batteries is less than 1°C, and the maximum difference in Tmin is less than 1.5°C. Therefore, the liquid cooling system’s overall battery heat dissipation efficiency has somewhat increased. Fig 21. Initial structure and optimized structure Battery Tmax and Tmin.

Update Information

- Which lithium battery pack has the best price

- Italian 21700 lithium battery pack

- Zero cycle battery secondary lithium battery pack

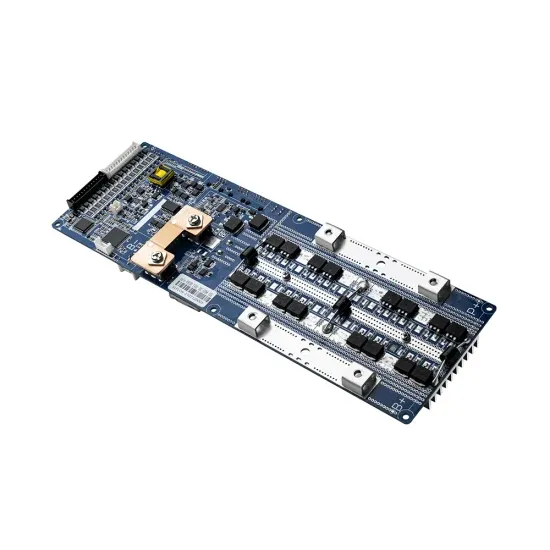

- Lithium battery pack active balancing BMS passive balancing

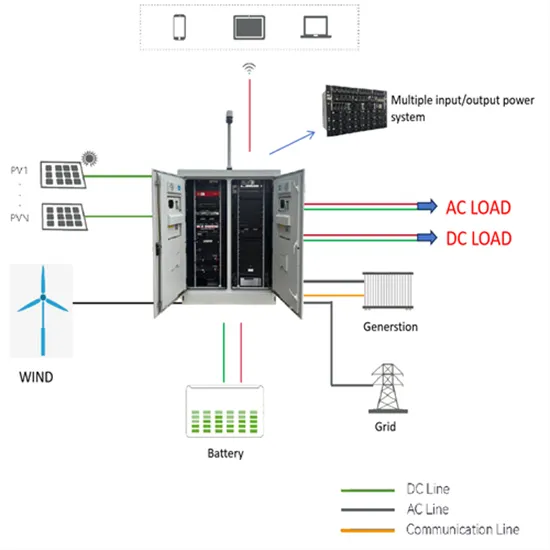

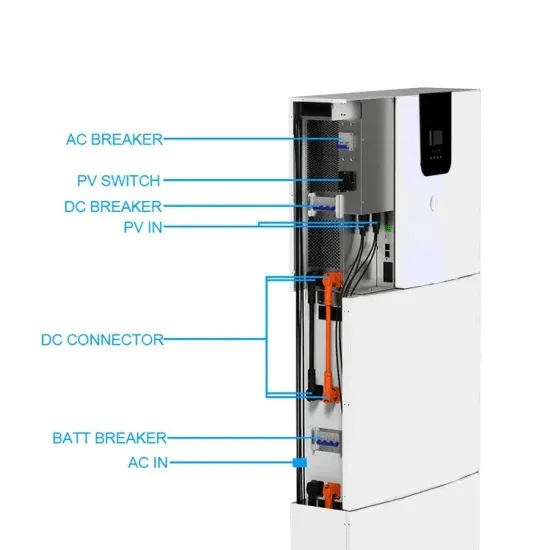

- The role of lithium battery pack with inverter

- Lithium iron phosphate battery pack press assembly

- What is MOS for lithium battery pack

- Which battery cell is better for Roman lithium battery pack

- Manila lithium battery pack company

- Lithium iron phosphate battery pack 25 6v71 5ah

- Timbu lithium battery pack customization

- Telecom site lithium battery pack 12v battery cabinet

- Assembly 24V lithium iron phosphate battery pack

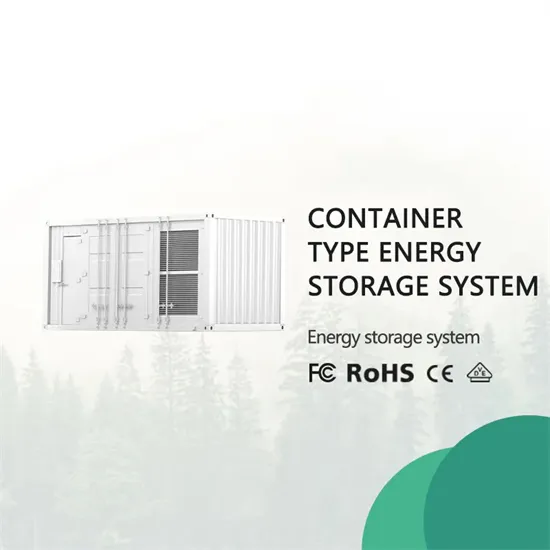

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.