Can An Inverter Charge A Battery? Understanding Its Role In Charging

Feb 2, 2025 · When connected to a battery, the inverter-charger will regulate the charging process, often featuring multiple charging stages. This ensures the battery is charged

A Multilevel Inverter With a Single Battery Source and a High-Frequency

Apr 18, 2025 · This study presents a novel multilevel inverter drive topology, which is powered by a single battery source and uses a small, affordable high-frequency link (HFL) to generate

Battery charging technology over view

Aug 22, 2022 · A typical high frequency battery charger incorporates a front-end AC-DC rectifier to generate anunregulated DC input voltage, a high frequency (HF) power converter that

How to Choose the Right Inverter for Lithium Batteries?

Apr 11, 2025 · Lithium batteries require inverters with precise voltage compatibility (e.g., 12V, 24V, or 48V systems) and stable charging profiles. Unlike lead-acid batteries, lithium variants

A high-power high-frequency self-balanced battery charger for lithium

Sep 1, 2021 · The charging and the balancing experimental results performed for 8 battery modules include 48 lithium-ion cells demonstrate simultaneous charging and balancing

Wireless power transfer pulse charging of lithium-ion battery

Nov 20, 2023 · The LCC-Series compensation topology was chosen because it can meet the requirement of minimizing output characteristics'' reliance on variations in Li-ion battery

An optimal self-heating strategy for lithium-ion batteries

Jan 15, 2024 · Therefore, a high-frequency battery self-heater is more suitable for lithium-ion batteries. It is of practical significance to develop high-frequency self-heaters for lithium-ion

The effects of high frequency current ripple on electric

Sep 15, 2016 · In addition, for a fully charged lead–acid battery, high-frequency ripple can be destructive through overcharge, especially due the large differences in electrochemical

10. Charger Settings

Sep 17, 2024 · This can, among others, be due to a low AC input current limit in combination with a high load; high environmental temperature; too high ripple voltage due to improper cabling.

Do I Need a Special Inverter for a Lithium Battery?

Oct 25, 2024 · Yes, using a lithium battery often requires a special inverter designed to handle the specific voltage and charging characteristics of lithium technology. Unlike traditional lead-acid

A high-power high-frequency self-balanced battery charger for lithium

Sep 1, 2021 · Here, a phase-shifted full-bridge (PSFB) converter with a current doubler rectifier and a voltage multiplier circuit for lithium-ion batteries is proposed. By combining both

Whc High Frequency Pure Sine Wave Power Inverter MPPT Charge

4 days ago · Whc High Frequency Pure Sine Wave Power Inverter MPPT Charge Controller off Grid Hybrid Solar Inverter for Lead-Acid Lithium Battery, Find Details and Price about Solar

High-Efficiency Volker Split Phase Inverter for Lithium Batteries

Aug 15, 2025 · Volker split phase hybrid inverter compatible with lithium battery 3000w. 4.Selectable input voltage range for home appliances and personal computers. This 3200W

Can a Lithium Battery Be Charged by an Inverter?

Oct 25, 2024 · Yes, a lithium battery can be charged by an inverter, provided the inverter is designed for this purpose. Typically, inverters convert DC power to AC power, but certain

Can be a high frequency inverter connected with lithium battery

Jun 4, 2021 · To say you were connected lead-acid battery to a high frequency inverter, is it possible to be replaced by gel or lithium battery? Since the voltage and current range of each

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

How Do High-Frequency Inverters Boost EV Charging?

In EV charging stations, inverters switch AC from the grid to DC for batteries, or the other way around, depending on the charger. For fast DC chargers, high-frequency inverters handle this

What Is A Lithium Ion Power Inverter?

Jun 3, 2025 · A lithium-ion power inverter is an integrated system combining high-capacity lithium-ion batteries with electronic circuitry to convert DC power to AC electricity (110V/220V). These

High Frequency Charge-Invert Integrated Machine-Dongguan Lithium

Dongguan Lithium Valley Energy Co., Ltd. is a subsidiary of Zongshen Group (stock code: 001696). Established in 2013, it is a national high-tech enterprise specializing in energy

5 FAQs about [High frequency inverter to charge lithium battery]

How to charge a lithium ion battery?

The simultaneous charging and balancing mechanisms There are different methods to charge lithium-ion batteries including constant-current constant-voltage (CCCV) and multistage constant current (MCC) methods. Each charging method has significant effects on the battery aging, battery degradation, and charging management.

What is a lithium ion battery?

Lithium-Ion traditional 1. Introduction Due to high energy storage, low self-discharge rate, long lifespan, and no memory effect, compared with traditional batteries , the lithium-ion batteries are widely used in different applications.

How Lithium ion cell charging process works?

According to the lithium-ion cell charging profile , , during the constant current (CC) charging process, battery string is charged with the constant current ( I c c) and the output voltage is monitored. During this process balancing circuit generates equalizing current which charges all the cells.

Why are lithium ion cells connected in series or parallel?

Since the voltage value of a single lithium-ion cell is low, approximately 4.2 V, these cells are connected in series or/and parallel for achieving higher voltages or/and capacities , , , . Generally, an energy storage system (ESS) consists of two parts; battery charger and battery management system (BMS).

Why is CCCV method selected to charge the batteries?

Therefore, the CCCV method is selected to charge the batteries due to its simplicity and low-cost implementation. According to the lithium-ion cell charging profile , , during the constant current (CC) charging process, battery string is charged with the constant current ( I c c) and the output voltage is monitored.

Update Information

- Lithium battery packs charge and discharge quickly

- High frequency inverter with water cooling

- Ulaanbaatar high frequency inverter installation

- Lead-acid lithium battery plus inverter

- Korean high frequency inverter installation

- 20v lithium battery inverter

- The best brand of high frequency inverter

- How long does it take to charge a 3 2v lithium battery with a 6v 35 watt solar photovoltaic panel

- High frequency inverter converted to water cooling

- Sea Island 2025 Type A High Frequency Inverter

- Inverter all-in-one machine accessories lithium battery

- Portable lithium battery sine wave inverter

- European lithium battery energy storage system inverter

Solar Storage Container Market Growth

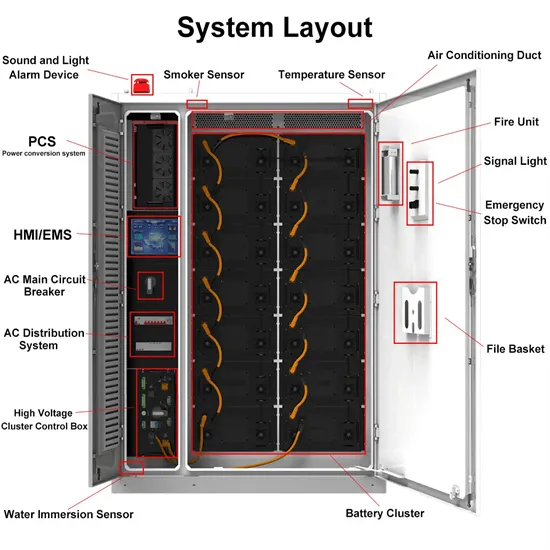

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.