Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Single-glass versus double-glass: a deep dive into module

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt

连云港神舟新能源有限公司 Dual-glass PV Module 双玻光伏

This manual contains the information of installation and safe operation of Shenzhou''s Dual-glass PV modules (hereafter referred to as"module"). All instructions should be read carefully before

Lamination process and encapsulation materials for

May 21, 2024 · Lamination process and encapsulation materials for glass–glass PV module design Gianluca Cattaneo1, Antonin Faes1, Heng-Yu Li1,2, Federico Galliano1,2, Maria

GLASS DISTILLATION (DOUBLE) – Optics Technology

The distillation apparatus consists of boiler with heating elements embedded in glass and fused in spiral type coil internally of the bottom and tapered round glass, suitable to work on 220 Volts

Latest Technology Production of N-Type Double Glass and Single Glass

Apr 10, 2025 · Latest Technology Production of N-Type Double Glass and Single Glass a-Class Black for Solar Panel Photovoltaic Modules, Find Details and Price about Solar Panel Solar

What is the difference between a double-sided double-glass

May 22, 2025 · This design enables the module to have double-sided power generation capabilities. The lower layer of glass can stimulate the back of the battery cell to generate

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

全球首发!干掉IPS屏漏光"顽疾",揭秘SANC盛色全

Apr 19, 2021 · 4月1日,国内显示器知名品牌SANC盛色,正式发布了全球首创的全玻璃模组(All-glass module™格拉斯模组)。 该技术成功攻克了IPS屏漏

深度学习模块介绍 —— Hourglass Module

Nov 6, 2019 · Hourglass Module Hourglass模块设计的初衷就是为了捕捉每个尺度下的信息,因为捕捉像脸,手这些部分的时候需要局部的特征,而最后对人体

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Assessment of long term reliability of photovoltaic glass–glass modules vs. glass-back sheet modules subjected to temperature cycles by FE-analysis

6 FAQs about [Module TypeDouble GlassSingle Glass]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

Are double-glass modules better than single-sided glass panels?

However, advancements in glass technology have mitigated this issue to some extent. Weight: Double-glass modules are generally heavier than single-sided glass panels due to the additional glass layer. Applications: Double-glass modules are well-suited for environments with harsh weather conditions, high humidity, or corrosive elements.

Are double glass modules better than traditional modules?

Compared to traditional modules with backsheet, modules with double glass are stronger and more durable, presenting less degradation due to thermal cycling stress. Results from the thermal cycling test up to 400 cycles show about 35% to 43% less degradation with double- glass modules than with traditional modules with backsheet (Fig. 3).

What is tempered glass solar module?

Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and solar cells against physical stress, snow, wind, dust and moisture etc, at the same time guaranteeing that the sunlight can go in. The backside is generally protected by an opaque sheet called the backsheet.

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is the difference between double-glass solar panels and single-sided solar panels?

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which can impact their durability, performance, and applications. Construction: Double-glass modules consist of two layers of glass sandwiching the solar cells and other components.

Update Information

- 9BB double glass module

- What is a single crystal double glass module

- N Djamena polycrystalline photovoltaic module glass

- Bloemfontein double glass photovoltaic module manufacturer

- Buenos Aires Glass PV Module Sales

- Double glass module standard

- All black single glass module

- Bulgarian thin film photovoltaic module glass

- There are several types of photovoltaic module glass

- Double glass module recommendation

- Kinshasa double glass photovoltaic module price

- Double glass module bvd

- Tuvalu double glass photovoltaic module manufacturer

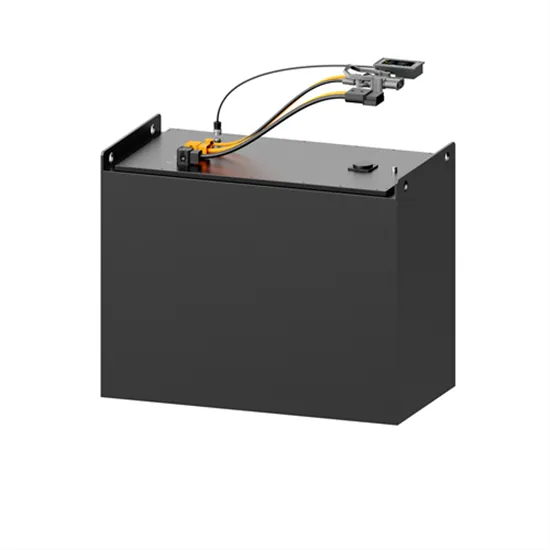

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.