Voltage Control Methods of Inverter – PWM

Feb 12, 2022 · The voltage control is primarily achieved by varying the firing angle of the ac voltage controller that feeds the ac load. In this method, there is a

Which inverter is the best to work in low DC voltage?

Dec 22, 2022 · The maximum voltage allowed by the DC input of the inverter refers to the highest of strings of DC input, not the sum of all string voltage. For example, if you have 20 panels,

Inverter input voltage: what it means, choosing the right one

Jun 27, 2025 · Learn about inverter input voltage and how to choose the right hybrid or voltronic solar inverter in Pakistan. Discover top tips and why ANICSUN leads the market.

Inverter Basics: Classification and Applications

Jan 3, 2021 · However, their voltage does vary according to the load applied. In this type, a current link (inductor) is provided in between the dc source and the

Introduction to inverters: structure, operating

May 24, 2024 · Discover the basics of inverters - their structure, operating principles, and functions. Explore Junchipower''s expertise in this informative

Inverter Specifications and Data Sheet

Jul 3, 2025 · One of the most significant ways input voltage affects a power inverter is efficiency. Every inverter has an optimal input voltage range where it operates most efficiently. If the input

CHAPTER 2

Dec 22, 2023 · generator. The filter capacitor across the input terminals of the inverter provides a constant dc link voltage. The inverter therefore is an adjustable-frequency voltage source. The

Interpreting inverter datasheet and main parameters | AE 868

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array. PV

Inverter input voltage: what it means, choosing the right one

Jun 27, 2025 · Solar inverter input voltage is the voltage that the solar inverter receives from any source; either energy generating source or energy storing source. That means that inverter

The starting voltage of the inverter is higher than the minimum voltage

In photovoltaic inverters, there is a rather strange parameter, that is, the inverter input starting voltage. This voltage is approximately 30V higher than the minimum operating voltage. For

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

What is an inverter? | inverter

Aug 11, 2019 · The inverter is made of inverting circuit, logic control circuit and filtering circuit, mainly including input interface, voltage start circuit, MOS switch, PWM controller, DC

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · The output voltage of an inverter is determined by the DC input voltage and the modulation index. The modulation index represents the ratio of the inverter''s AC output

Understanding inverter voltage

Jan 10, 2024 · Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function

Exceeding Inverter Limits

Feb 2, 2020 · The general rule of thumb is that your inverter Max Input voltage must be greater than Voc x 1.2, otherwise the inverter will shut down (if you are very lucky) or fry (more likely).

Sub: Fundamentals of CMOS VLSI Sub code: 10EC56

Feb 4, 2019 · Graphical Derivation of Inverter DC Characteristics: The actual characteristics are drawn by plotting the values of output voltage for different values of the input voltage. We can

6 FAQs about [Which is the input voltage of the inverter]

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

What determines the output voltage of an inverter?

The output voltage of an inverter is determined by the DC input voltage and the modulation index. The modulation index represents the ratio of the inverter’s AC output voltage to its maximum possible AC output voltage.

How much power does an inverter need?

It’s important to note what this means: In order for an inverter to put out the rated amount of power, it will need to have a power input that exceeds the output. For example, an inverter with a rated output power of 5,000 W and a peak efficiency of 95% requires an input power of 5,263 W to operate at full power.

Update Information

- High frequency inverter input voltage

- Inverter input voltage fine-tuning

- Sanaa PV inverter input voltage

- Car inverter adjusts input voltage

- The voltage is low after inverter rectification

- What voltage should I buy for a 1000w inverter

- High voltage inverter outdoor large capacitor

- How much voltage does a 3000w inverter have

- Inverter power AC voltage

- What is the maximum voltage that a 48v inverter can connect to

- Inverter voltage universal

- How much voltage can the inverter carry

- Ultra-high voltage transmission inverter

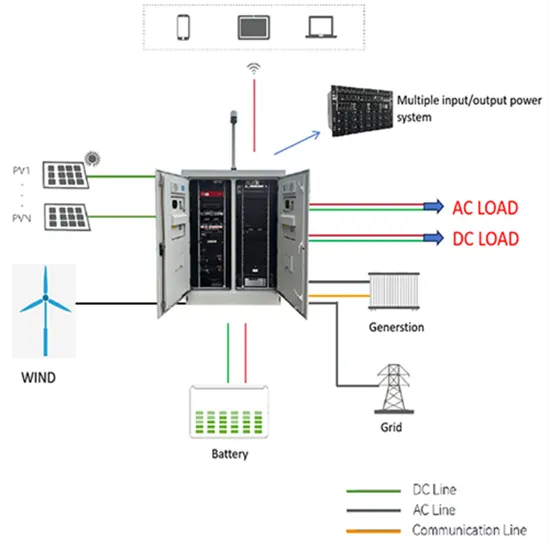

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.