How to solve the problem of inverter low voltage tripping?

Nov 17, 2024 · Under normal circumstances, the power supply voltage is 380V, with an allowable error of -15%~10%. After three-phase bridge full-wave rectification, the intermediate DC

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · Check the Battery: Ensure that the battery is fully charged. If the battery voltage is too low, the inverter may not turn on. Use a multimeter to measure the voltage. If it''s below the

What is inversion mode of rectifiers? – WisdomAnswer

Nov 16, 2020 · What is rectification mode of converters? Rectification converts an oscillating sinusoidal AC voltage source into a constant current DC voltage supply by means of diodes,

Summary of common causes and countermeasures of inverter

After the load is applied, the DC voltage after rectification is low, causing undervoltage failure. Countermeasure: Check whether the circuit breaker or contactor contacts of the inverter power

Input and Output Voltage of a Full bridge rectifier

Apr 11, 2021 · I know If we provide a sinusoidal AC Voltage across the Inputs of a full bridge rectifier we get a fluctuating DC Voltage (more or less) with the

Understanding Bridge Rectifiers: Principles,

Jul 9, 2024 · The design of the bridge rectifier not only improves the rectification efficiency but also provides a stable DC output voltage. This article will discuss

Why there is no output voltage after the inverter

Apr 9, 2024 · Cause Analysis: The DC voltage between the main circuit P and N is normal, indicating that the rectification, current limiting and energy storage

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Dec 17, 2023 · One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible

The reason and check method of inverter low voltage and

Jun 7, 2025 · 1. The low voltage of the inverter mainly refers to the low voltage of the intermediate DC circuit. Generally, the reason for the low voltage of the intermediate DC circuit comes from

What is rectification and its types?

May 16, 2023 · Using a rectifier in the power supply helps in converting AC to DC power supply. Bridge rectifiers are widely used for large appliances, which can convert high AC voltage to

Fault Detection and Troubleshooting in a PV

Jun 21, 2021 · As per fault severity it may completely shut down or partially operate the inverter with reduced load. After the fault rectification manually by

10 common inverter failure and the solutions –

Nov 15, 2023 · Common causes and solutions for low DC input voltage: The open circuit voltage of the string should be much greater than the minimum input

Full Wave Rectifier and Bridge Rectifier Theory

Aug 13, 2013 · The full wave rectifier converts both halves of each waveform cycle into pulsating DC signal using four rectification diodes. In the previous power

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · Inverters play a crucial role in many modern systems, converting DC power from sources like batteries or solar panels into AC power that can be used by household

Inverter undervoltage fault causes and treatment methods

Reason: When the inverter power supply is out of phase, the three-phase rectification becomes two-phase rectification. After the load is applied, the rectified DC voltage is low, resulting in an

Synchronous rectification in high–performance power

Apr 1, 2023 · Synchronous switching power converters give better performance than nonsynchronous converters in low output voltage, high output current systems applications.

voltage after rectification too low?

Jul 1, 2022 · The AC voltage output of the transformer is 18V, but after the rectification it drops to 12V DC, so obviously the regulators can''t do their job. What could be the problem?

Synchronous rectification boosts efficiency by reducing

Apr 30, 2013 · Typical application Two typical boost applications can be used to demonstrate the difference between synchronous and nonsynchronous rectification. The first is a lower-input

How to Address Inverter Low Voltage Issues for

Apr 3, 2025 · Inverter low voltage is a common issue that can disrupt industrial operations, affecting automation systems and energy management efficiency.

6 FAQs about [The voltage is low after inverter rectification]

Why is the DC voltage low after rectification?

After the load is applied, the DC voltage after rectification is low, causing undervoltage failure. Countermeasure: Check whether the circuit breaker or contactor contacts of the inverter power supply are in good contact, whether the contact resistance is too large, whether the input voltage is normal, etc.

What happens if a solar inverter is too low?

The open circuit voltage of the string should be much greater than the minimum input voltage of the inverter; if there are too few modules in series, the open circuit voltage of the string will be too low, resulting in no display on the inverter screen. Solution: Increase the number of solar panels in series.

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

What causes undervoltage failure in an inverter?

1. Power supply phase loss Cause: When the inverter power supply phase is lost, the three-phase rectification becomes two-phase rectification. After the load is applied, the DC voltage after rectification is low, causing undervoltage failure.

Update Information

- 12V inverter voltage is low

- Inverter rear bridge output voltage is too low

- Can the inverter convert high voltage into low voltage

- Nicaragua low voltage inverter manufacturer

- Low voltage inverter price

- Nouakchott professional low voltage inverter manufacturer

- The output voltage of the photovoltaic panel becomes low

- Abu Dhabi voltage stabilizer inverter price

- Voltage inverter voltage regulation

- Low Voltage Flow Batteries

- Inverter output voltage is slow

- Inverter voltage change

- 100kv ultra high voltage inverter price

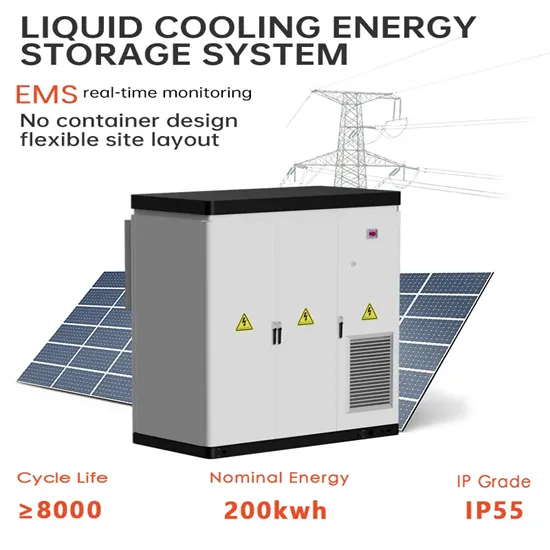

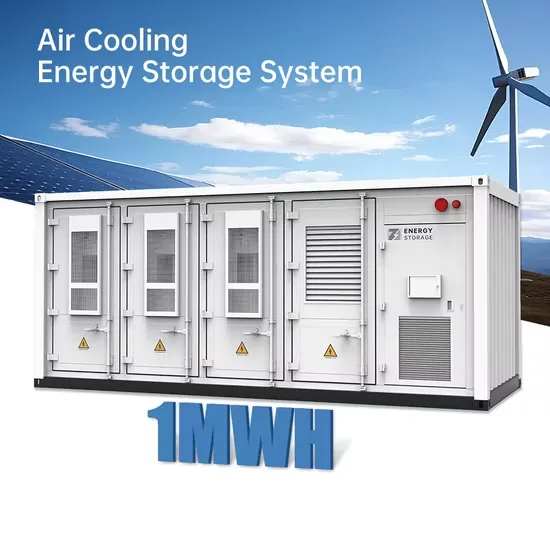

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.