Performance enhancement of a multilevel inverter in

Jun 1, 2025 · Cost-effective and efficient solution for enhancing inverter performance in RES. This paper introduces the Equilibrium Optimizer (EO) to enhance the performance of a single

Optimize Your Solar Inverter Settings Today!

Jan 9, 2024 · Parameter optimization: Fine-tuning various parameters, such as power output limits and voltage regulation, to optimize the operation of your inverter. Load optimization:

Deep Reinforcement Learning for Optimizing Inverter

Nov 5, 2024 · This paper presents novel methods for tuning inverter controller gains using deep reinforcement learning (DRL). A Simulink-developed inverter model is converted into a

Optimal designing and parameter selection of voltage

Sep 19, 2024 · Two techniques are used to improve inverter stability: (A) altering the grid-side inductance, and (B) changing the VSI''s output impedance. The goal is to optimize the VSI

Investigation of the modulation index tuning advantages

6 days ago · This paper demonstrates that the possibility to regulate the modulation index of the Pulse-Width Modulation (PWM) scheme by adjusting the DC bus voltage could improve the

9. Inverter Settings

Sep 17, 2024 · To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be

Grid-connected PV inverter system control optimization

Aug 7, 2025 · In this study, a 3-phase voltage source inverter (VSI) is used in the grid-tied photovoltaic system depicted in Fig. 1 and its corresponding simulation in Fig. 2. The PV array,

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

Hitachi series inverter 22, B Group: Fine-tuning Functions

1 24 34 34 Download 34 pages, 352.7 Kb 22"B" Group: Fine-tuning Functions A146 ADD direction select • 00 Plus (adds A145 value to output frequency) • 01 Minus (subtracts A145 value from

General Inverter Troubleshooting | Magnum Dimensions

4 days ago · General Inverter Troubleshooting The following is a quick reference for Magnum Energy inverter/charger to diagnose typical symptoms. Always refer to your full user manual.

Voltage Control Methods of Inverter – PWM

Feb 12, 2022 · The voltage control is primarily achieved by varying the firing angle of the ac voltage controller that feeds the ac load. In this method, there is a

LETTER IEICE Electronics Express, Vol.13, No.17, 1 9 A

Abstract: This paper proposes a process, voltage, temperature (PVT) independent Schmitt trigger with fully adjustable hysteresis threshold vol- tages. These characteristics are attributed to the

Low power, high resolution CMOS variable-delay element

Jun 1, 2012 · This letter proposes a novel CMOS variable-delay element (VDE). It employs a RC-based differentiator to control the pMOS transistor of a CMOS inverter, whose delay time

Optimal Structures for Voltage Controllers in Inverters

Aug 17, 2018 · In this paper, we study the optimal structure of voltage controllers for ac inverter systems. In deriving the controller, we present a system-atic design framework for designing

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · Inverter Voltage Formula: Inverter voltage (VI) is an essential concept in electrical engineering, particularly in the design and operation of power electronics systems. It describes

Inverter input dc voltage control by the MPPT algorithm;

Inverter input dc voltage control by the MPPT algorithm; when the PV voltage is lower than the minimum voltage of the single-stage PV inverter, the boost stage is engaged and the MPPT

Pairing voltage-source converters with PI tuning controller

Sep 1, 2024 · This paper introduces a novel method to improve the efficiency of grid-connected wind-solar cogeneration systems. It involves the integration of Voltage-Source Converters

6 FAQs about [Inverter input voltage fine-tuning]

What are inverter settings?

Inverter Settings 1. To set output voltage of inverter - This is normally 230 Vac. Possible values 210V ~ 245V. 2. Used to enable/disable the internal ground relay functionality. Connection between N and PE during inverter operation. - The ground relay is useful when an earth-leakage circuit-breaker is part of the installation.

Why are inverter drives important for industrial automation?

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic parameters like voltage, frequency, and acceleration are well-known, advanced parameter settings allow for greater performance optimization, system protection, and intelligent automation.

How to tune inverter control gains?

Two approaches are developed for tuning inverter control gains: a fixed gain method, where controller gains are embedded as weights of actor network, and an adaptive gain method, where gains are generated dynamically as actor network outputs.

What are inverter parameters?

Inverter parameters include motor power, current, voltage, speed, and maximum frequency, all of which can be directly obtained from the motor nameplate. Resonance might occur at certain frequency points, particularly with taller structures. When controlling compressors, it's crucial to avoid frequencies that could cause surge.

What are inverter output frequency limits?

This sets the upper and lower limits for inverter output frequency to protect equipment from damage due to setting errors or external signal failures. These settings should be based on practical needs and can serve as speed limits for applications like conveyor belts, where setting a lower maximum frequency reduces mechanical wear.

How to debug a frequency inverter?

Therefore, debugging a frequency inverter begins with correctly setting its parameters. Here are 16 basic methods for setting inverter parameters for reference: This refers to speed control, torque control, PID control, or other methods.

Update Information

- High frequency inverter input voltage

- Sanaa PV inverter input voltage

- Car inverter adjusts input voltage

- Inverter output voltage is slow

- Inverter voltage universal

- Inverter voltage amplification price

- What inverter is used for high voltage grid connection

- Voltage generated by a 5 kW inverter

- Photovoltaic inverter capacitor withstand voltage value

- Inverter voltage suppression

- New Zealand low voltage inverter wholesale price

- The waveform of the voltage source inverter output

- Inverter selection voltage

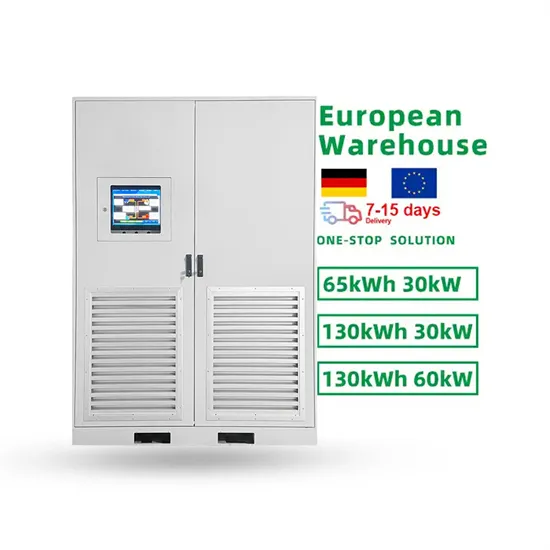

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.