What 3000W inverter to pick.

Jan 16, 2025 · It may be "inverter prepped", but the odds of it being prepped to support the necessary current for a 3000w inverter is pretty slim. Going to need 4/0 cable (212 kcmils) or

Inverter Cable Size Calculator & Formula Online Calculator

Oct 2, 2024 · Understanding the appropriate cable size for your inverter is essential to ensure efficient power transmission and prevent potential hazards. This calculator aids in determining

What Can A 1000W Power Inverter Do For Your System? 5

Jun 25, 2025 · In an era of mobile operations, decentralized workspaces, and unpredictable power availability, having access to stable AC electricity—anytime, anywhere—is more

1000W Inverter: Ultimate Guide to Choosing the Best in 2024

Aug 19, 2024 · When selecting a 1000W inverter, it''s crucial to consider factors like: Keeping these factors in mind, we should delve further into the evaluation of power requirements. To

What Charge Controller Size Do I Need For 1000 Watt Solar

By dividing the solar power watts with the battery voltage and adding 25% for safety, you get the ideal charge controller size. Calculate Charge Controller Size For 1000W Solar Array In the

1000W Power Inverter Guide: Usage, Selection Tips, And

Jun 12, 2025 · A 1000W power inverter has emerged as a versatile tool that converts DC electricity—typically from a battery or solar panel—into usable AC power. Whether used in

What Size Fuse for 400, 750, 1000, 1500, 2000, 3000-watt Inverter

Quick Anwser The 400, 750, 1000, 1500, 2000, 3000 watt inverter would require 40A, 75A, 100A, 150A, 200A, 300A respectively. Remember that the size of the Fuse would also determine

1000W Power Inverter Guide: How to Choose

May 21, 2025 · Input voltage should match your existing DC power source. 12V inverters are suitable for smaller systems, like vans or single-battery solar kits.

How to size an inverter that can run your air

Feb 10, 2024 · In this article, I''ll explain in detail the main specifications to look at when shopping for an inverter that can run your air conditioner. I get

What Size Battery Do I Need for a 1000W Inverter?

Dec 13, 2023 · To power a 1000W inverter, you typically need a battery with a minimum capacity of 100Ah if you plan to run it for about one hour. However, the actual size may vary based on

Guide to 1000W Inverter: What Can a 1000W Inverter Run?

May 23, 2025 · From charging your laptop and preparing your morning coffee to operating small appliances or even life-support medical equipment, a 1000W inverter in a portable power

What size wire for a 1000 Watt inverter?

Jun 7, 2013 · The #4 wire will probably work OK for most stuff. But you may expect some voltage drop when you run close to the maximum 1000W of appliance load on it. This is because

1000W Power Inverter Guide: Usage, Selection Tips, And

Jun 12, 2025 · For a 1000W power inverter, using the correct cable gauge—typically 8 AWG or thicker for short distances—is essential to handle the current without overheating or causing

What Inverter Size Do I Need to Run a Coffee Maker?

Do not let your inverter run at its stated capacity limit. If after running your coffee maker and other appliances your inverter reaches its limit, it is time to upgrade. Whether it is sola panels,

Inverter Size Calculator | Find Your Perfect Power Match

Apr 25, 2025 · Quickly size your campervan inverter. Add appliances, see min & max loads, and compare value vs premium options. Efficient, reliable, & easy.

Can One 12 Volt Battery Run a 1000 Watt Inverter?

Apr 29, 2025 · Yes, a single 12-volt battery can run a 1000-watt inverter, but the runtime depends on several factors such as the battery''s capacity, the inverter''s efficiency, and the load

6 FAQs about [What voltage should I buy for a 1000w inverter]

How much power does a 1000 watt inverter draw?

Generally, a 1000 Watt inverter can draw up to 120 Amps if the battery bank is rated at 12 Volts, or up to 60 Amps if the battery bank is rated at 24 Volts. If the battery bank is rated at 48 Volts, the 1000 Watt inverter will not draw more than 30 Amps. This is assuming the 1000W inverter is about 85% efficient.

What size wire do I need for a 1000 watt inverter?

The required wire size for a 1000 Watt inverter will mainly depend on the Voltage of the battery bank. Generally, you’ll need a 1/0 AWG copper wire if the 1000 Watt inverter is running on a 12V battery bank, or a 3 AWG copper wire if the 1000W inverter is running on a 24V battery bank.

How do you calculate a 1000 watt inverter?

Inverter’s Maximum Amp Draw (in Amps) = (Inverter’s Continuous Power rating (in Watts) ÷ Inverter’s efficiency (%)) ÷ Lowest Battery Voltage (in Volts) For example, let’s say our 1000 Watt inverter is 85% efficient and is running on a 24 Volt battery bank.

What is the rated power of a 1000W inverter?

The rated power of a 1000W inverter is the maximum power it can provide (1000W), which means that the power it can consume at any given time is 1000W. For example, during a power outage, you can use a 1000W inverter to support the operation of some small appliances and lighting equipment, such as light bulbs, TVs, laptops, etc.

What is a 1000 watt inverter?

The "wattage" of an inverter directly correlates to how much power it can continuously supply to AC appliances. A 1000W inverter can provide a continuous output of up to 1000 watts of AC power. It typically also has a "surge" rating (e.g., 2000W for a few seconds) to handle the brief power spikes needed to start certain motor-driven appliances.

What breaker should a 1000 watt inverter use?

If your 1000 Watt inverter is running on a 12V battery, the circuit breaker (or fuse) should be rated at 150 Amps. If your 1000W inverter is running on a 24V battery, the circuit breaker should be rated at 80 Amps. If the battery bank is rated at 48V, the circuit breaker or fuse should be rated at 40 Amps.

Update Information

- What does dual voltage inverter mean

- What is the auxiliary power supply voltage of the inverter

- What is the normal inverter voltage in Greece

- What is the AC voltage of the inverter 220v

- What is the maximum voltage that a 48v inverter can connect to

- What inverter is used for high voltage grid connection

- What is the voltage of the inverter capacity

- Inverter for non-high voltage power users

- Ultra-high voltage transmission inverter

- How much voltage can the inverter carry

- 220v AC voltage inverter

- Inverter dual voltage conversion

- The voltage is low after inverter rectification

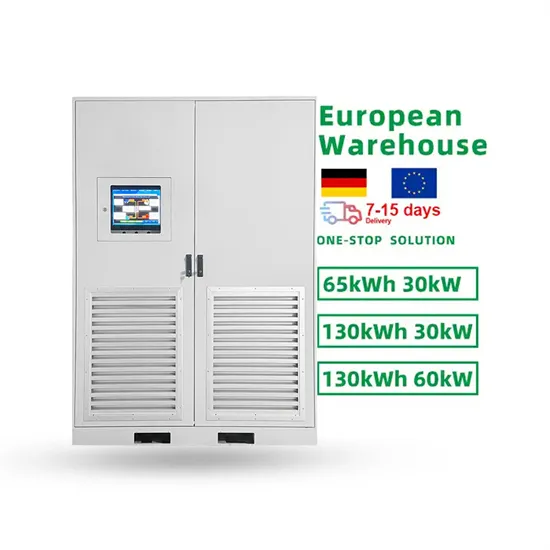

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.