A real case of thin film PV alternatives to cSi based on a-Si

Feb 15, 2025 · The measurement of photovoltaic panels of thin film technologies is not a totally obvious matter. For example, the output power of an a-Si panel depends on panel history of

Thin-Film Solar Panels

Feb 27, 2021 · Thin-Film solar cells are by far the easiest and fastest solar panel type to manufacture. Each thin-film solar panel is made of 3 main parts: Photovoltaic Material: This is

Thin-Film Solar Panels: Everything to Know

Apr 25, 2023 · Factors affecting the lifespan of thin-film solar panels include the quality of materials used in their manufacturing, the specific type of thin-film

Methodological approaches for resource recovery from end

Jan 1, 2025 · Generations of photovoltaic technologies, namely crystalline silicon, thin-film, and third-generation solar panels, share the goal of achieving waste reduction through useful

A comprehensive review on life cycle assessment of

Oct 1, 2023 · A critical assessment of the results of 58 LCA studies was conducted and compared with traditional silicon based solar cells. Results indicate that emerging thin film solar cells hold

What Are Thin Film Solar Cells? A Complete Guide

Feb 11, 2025 · Part 1. What is a thin film solar cell? A thin-film solar cell is a photovoltaic device that converts sunlight into electricity. Unlike traditional

Thin-Film Solar Panels: How They Work, Pros

Sep 18, 2023 · Thin-film solar panels are photovoltaic solar panels made from thin layers of semiconductor materials deposited on a low-cost substrate, like glass

Advancements in recycling technologies for waste CIGS photovoltaic modules

Sep 1, 2024 · To mitigate the potential environmental and human health impacts of waste Copper–indium–gallium–diselenide (CIGS) thin-film photovoltaic (PV) modules, effective

Exploring Thin Film Solar Panels: How Efficient

Nov 17, 2023 · When it comes to real-world efficiency, thin-film solar panels typically demonstrate rates between 7% to 13%. This range, while historically

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Thin-film solar cells: review of materials, technologies and

Apr 3, 2007 · The recent boom in the demand for photovoltaic modules has created a silicon supply shortage, providing an opportunity for thin-film photovoltaic modules to enter the market

Advantages and Disadvantages of Thin Film

Sep 1, 2023 · Thin-film solar cells are a type of photovoltaic technology that differs from traditional crystalline silicon solar cells. They are made by depositing one

Solar Photovoltaic Manufacturing Basics: A Beginner''s Guide

2 days ago · Final Conclusion Solar photovoltaic manufacturing is a blend of science, engineering, and cost optimization. From silicon PV and thin film PV to racking systems and power

Thin-Film Solar Photovoltaics: Trends and Future Directions

Dec 5, 2024 · Thin-film solar cell can be cost-effective because of minimal material usage, flexibility, and potential high efficiency. The traditional thin-film solar technologies include

Advancements in photovoltaic technology: A comprehensive

Apr 1, 2025 · This review provides a comprehensive analysis of recent advancements in PV technology and presents forward-looking insights into future trends. Beginning with a historical

What are thin-film solar cells? description, and types

Sep 26, 2019 · Accelerated life tests of thin-film junction solar cells under laboratory conditions measured somewhat faster degradation than conventional PV, while a lifespan of 20 years or

Flexible Photovoltaic Solar Design | SpringerLink

This chapter presents descriptions of flexible substrates and thin-film photovoltaic, deepening the two key choices for the flexible photovoltaic in buildings, the thin film, as well as the organic

Lifespan of thin-film solar panels

How long do thin film solar panels last? With proper care and maintenance, thin film solar panels can last for several decades, often coming with warranties for 20-25 years. Analysing this

What are thin-film solar cells? description, and types

Sep 26, 2019 · Silicon modules are divided into three categories: Amorphous silicon photovoltaic cells Multicrystalline tandem photovoltaic cells Multicrystalline silicon thin film on glass The

6 FAQs about [Thin-film photovoltaic module lifespan]

How long do thin-film solar panels last?

Thin-film solar panels typically have a shorter lifespan compared to monocrystalline solar panels. The average lifespan of a thin-film solar panel is around 10 to 15 years, while monocrystalline solar panels can last up to 25 years or more. However, the lifespan of a thin-film solar panel can vary depending on several factors.

What are the advantages and disadvantages of thin-film solar panels?

When compared with traditional, rigid solar panels, thin-film solar panels present several advantages and disadvantages. Thin-film solar panels’ subtle and sometimes incognito appearance often makes them more aesthetically pleasing than bulky rooftop panels.

What are thin-film solar panels?

Thin-film solar panels are the hope of the solar energy industry. Because of their cost, ease of manufacture, lightweight, flexibility, and variety of applications. And according to Solar Energy Hackers, Thin-Film technology is expected to surpass all the silicon-based solar panels in a few years.

Are thin film solar panels cheaper?

In most cases, though, thin-film solar panels require significantly less equipment to install than rigid solar panels, which can make them cheaper overall, especially if you do it yourself. Are thin-film solar panels worth it?

What is the life cycle of a thin film solar cell?

For commercial thin film solar cell technologies (a-Si, CIGS, CIS, CdTe, GaAs and tandem GaAs), the life cycle CED ranged from 684 to 8671 MJ/m 2 (median: 1248 MJ/m 2). This range was higher than emerging thin-film solar cell technologies (PSC, PSC tandem, DSSCs, OPV, CZTS, QD) that reported a CED range of 37–24007 MJ/m 2 (median: 721 MJ/m 2).

What are some examples of thin-film solar technology?

Today, two of the most common examples of thin-film solar technology include flexible solar panels (also known as amorphous solar panels) and solar shingles (also known as solar roof tiles).

Update Information

- Thin-film photovoltaic module quotation

- Thin-film photovoltaic module equipment

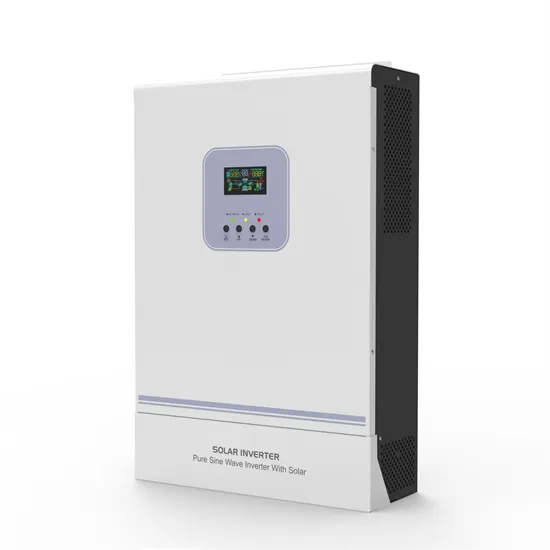

- Photovoltaic inverter communication module

- Double-glass photovoltaic module manufacturers

- Energy storage container solar photovoltaic module factory photothermal equipment

- Lifespan of photovoltaic panels

- Islamabad Photovoltaic Module Export

- Glass photovoltaic module installation angle

- Tuvalu double glass photovoltaic module manufacturer

- Number of photovoltaic module cells

- Solar photovoltaic module pressure equipment

- N Djamena polycrystalline photovoltaic module glass

- Latest photovoltaic module models and prices

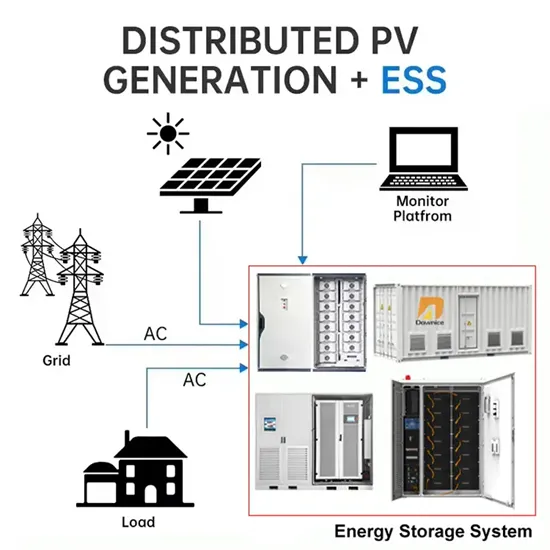

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

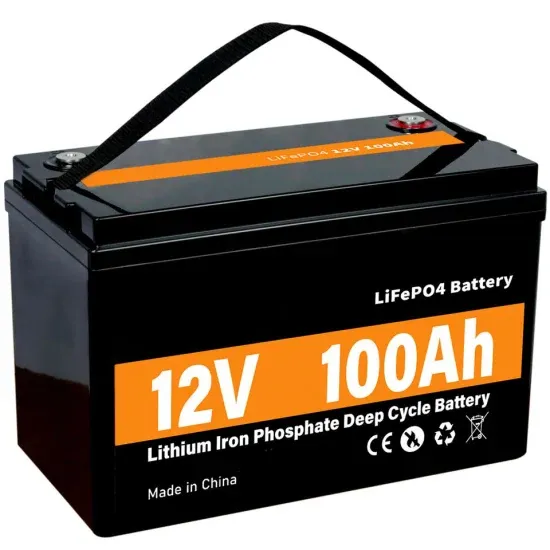

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.