DS 1-15 Roof Mounted Solar Photovoltaic Panels (Data

Feb 4, 2021 · 1.0 SCOPE This data sheet provides property loss prevention guidance related to fire and natural hazards for the design, installation, and maintenance of all roof-mounted

Structural Requirements for Solar Panels —

Feb 22, 2024 · Rooftop Solar Configurations Rooftop solar installations are an efficient way to harness solar energy for residential or commercial buildings.

PV Moduel Equipment

Oct 9, 2024 · SC Solar has advanced technology in TOPCon, HJT and perovskite cell and module equipment fields, and ranks first in the market share of solar module production line segment.

Severe Weather Considerations for Siting Solar PV Systems

Aug 23, 2024 · • PV modules and electrical equipment such as inverters, batteries, and transformers may need to be installed at a higher elevation and/or on concrete pads above the

iSolar – clean solar modules effectively and increase

Kärcher iSolar. The system solution for solar module cleaning. Debris from dust, soot and pollen can reduce the output of photovoltaic systems and solar thermal energy modules by up to

Can You Use A Pressure Washer To Clean Solar Panels

Jun 8, 2025 · But how does high-pressure cleaning work? High-pressure washing involves the use of specialized equipment that delivers a concentrated stream of water at an enhanced

Master Solar Panel Cleaning with a Pressure Washer

Apr 16, 2025 · Clean Solar Panels with a Pressure Washer To effectively clean your solar panels using a pressure washer, we understand that following the right steps is essential for

Solar Panel Lamination Process Explained

Dec 30, 2024 · Learn about the solar panel lamination process, its benefits, and the unique value that Bent River provides with their photovoltaic (PV) module laminator.

Shanghai yanzhi testing equipment Co.

Yanzhi 3d microscope is a 3D optical interferometric profiler based on phase-shift interferometry (PSI) Yanzhi solar cell quantum efficiency test system is a specialized system for testing the

An overview of solar photovoltaic panels'' end-of-life material

Jan 1, 2020 · End-of-life (EOL) solar panels may become a source of hazardous waste although there are enormous benefits globally from the growth in solar power gen

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · Turnkey Solutions for PV Modules Manufacturing We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their

Floating PV systems – an overview of design

May 21, 2024 · Representation of a floating solar plant Floating solar installations consist of floats/pontoons, module mounting structures, mooring system, PV modules, inverters, and

Effects of wind on cooling and performance of photovoltaic

Apr 15, 2024 · As photovoltaic (PV) power plants become more popular, it is important to understand how wind affects the temperature distribution and consequently performance of

Solar Production Equipment

Mar 5, 2025 · Manufacturers of solar module production equipment are an enduring link in the European solar PV industrial ecosystem. This report shines a light on these key actors of the

Solar photovoltaic module side pressure block

The solar PV module connected with irradiance, temperature, and panel voltage measurements is shown in Figure 3, where temperature (T) and solar irradiation (G) are the inputs of solar PV

Precautions for using solar photovoltaic module laminator.

Solar photovoltaic module laminator is a kind of equipment specially used in the production of solar photovoltaic modules. Its function is to heat-press and laminate modules of different

Solar panel production equipment and machinery

Oct 28, 2016 · Nowadays the solar panels'' production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and

光伏术语 | 光动百科PVMeng ,能源政策解读,光

Dec 17, 2018 · 1.1.1 光伏发电 1.1.1.1 光伏组件 PV module 又称太阳电池组件(Solar Cell module)。是将多个电气连接的太阳电池经封装形成在光照下具

Photovoltaic Meteorological Station: Functions, Advantages,

Mar 20, 2025 · photovoltaic meteorological station is a customized meteorological monitoring device for photovoltaic power generation systems, designed to provide real-time, high

光伏模块_百度百科

光伏模块是将太阳能转化为电能的装置,核心原理为光生伏特效应,即光照使半导体材料产生电位差实现光电转换,属于太阳能光发电技术范畴。其结构包含硅

6 FAQs about [Solar photovoltaic module pressure equipment]

What equipment do you need to make solar panels?

Main machinery: Solar simulator. Accessories: Laboratory accessories for quality control. Setting a production line of solar panels is a task that requires know-how and experience.

What is a solar laminator photovoltaic module?

Solar Laminator photovoltaic module. Lamination is one of the most critical processes in solar panel manufacturing; it ensures the quality and durability of the photovoltaic module. We can offer customised laminators to suit all production needs. Laminates the module components applying the right pressure and temperature.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

Who is Supo solar panel manufacturer?

Powered by dyyseo.com SUPO is a top brand solar panel manufacturing equipment manufacturer from China,export fully automatic solar panel production line,solar panel making machine,solar cell ter stringer,laminator,testing machine and tunrkey line solution,best factory layout plan.

How do solar thermal energy modules work?

Photovoltaic and solar thermal energy modules harness solar radiation and convert it to energy. But debris from dust, soot and pollen can reduce their output by up to 20%, reducing their efficiency. The natural power of rain, condensation and wind are nowhere near strong enough to clean the modules effectively.

Update Information

- Energy storage container solar photovoltaic module factory photothermal equipment

- How much does the Hargeisa smart photovoltaic module equipment cost

- Panama Colon Solar Photovoltaic Module Company

- Dili Solar Photovoltaic Module Factory

- Solar photovoltaic module production stopped

- Solar Photovoltaic Power Generation and Energy Storage Equipment

- Andorra solar photovoltaic module customization

- Home energy storage equipment brand new solar photovoltaic

- Black Mountain photovoltaic module equipment price

- Ukrainian solar photovoltaic module manufacturers

- Do Brazzaville solar photovoltaic panels make money

- Photovoltaic solar panels in Bangladesh

- Branded Small Base Station Equipment Solar Panel Factory

Solar Storage Container Market Growth

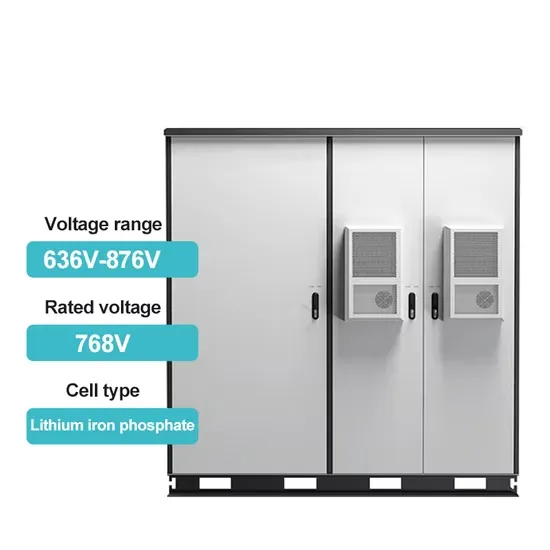

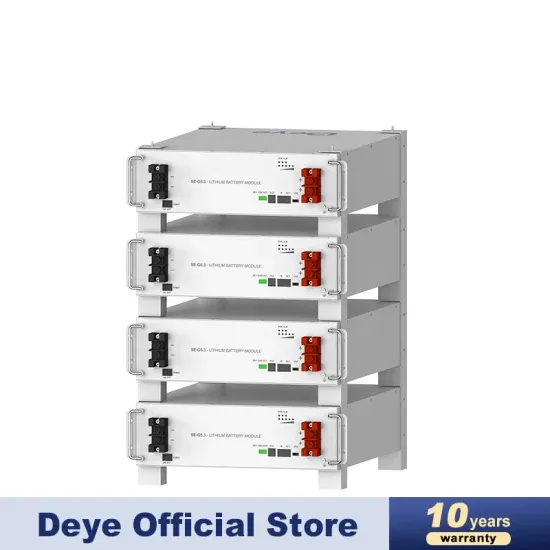

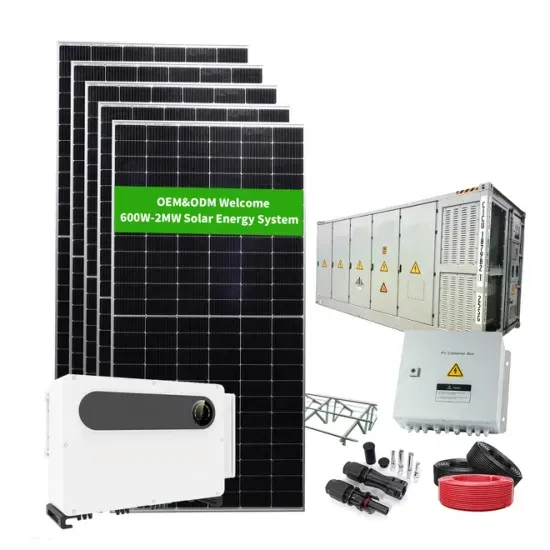

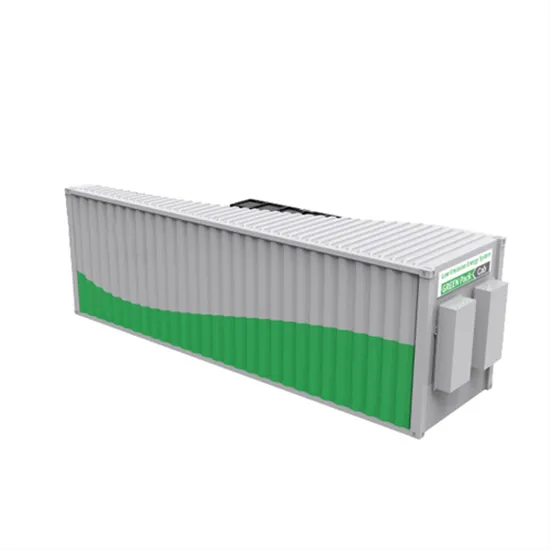

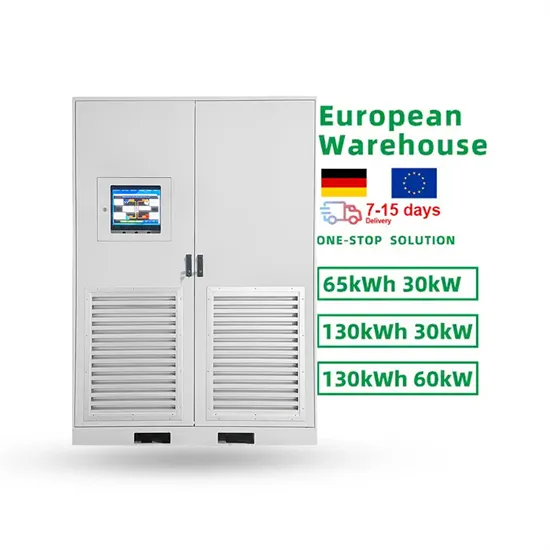

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.