Recycling of photovoltaic modules for recovery and

Apr 1, 2023 · Recycling of PV comprises repairing, direct reuse, and recycling of materials chemically and mechanically from different types of decommissioned photovoltaic modules.

Photovoltaic Panels Recycling Machines | SUNY GROUP

Jun 28, 2025 · The main process of PV panel recycling Currently, the recycling of photovoltaic panels consists of three main steps: dismantling → crushing and sorting → material reuse.

Photovoltaic panel solar panel glass removal machine

6 days ago · Introduction Photovoltaic panel de glassing machine is a device specifically designed for efficient and non-destructive separation of solar cells from glass backboards in photovoltaic

Development of eco-friendly pretreatment processes for

Oct 16, 2024 · This study examines the efficacy of photovoltaic (PV) recycling processes and technologies for the recovery of high-purity silicon powder from waste solar modules. In order

Full Automatic Solar Glass Separation Equipment Photovoltaic Module

Glass Separating & Collection Unit 1) Main functions: It can adapt to photovoltaic panels with a width of 800mm-1300mm, with flat surface and no curling edges. The adhesive strips above

Full Automatic Solar Glass Separation Equipment Photovoltaic Module

2. Remove the glass This equipment is specially designed for glassremoval equipment of photovoltaic modules, which can efficiently, quickly and safely remove glass from photovoltaic

Photovoltaic Solar Panel Recycling Machine Solar Panel Glass Separation

2. Remove the glass This equipment is specially designed for glass removal equipment of photovoltaic modules, which can efficiently, quickly and safely remove glass from photovoltaic

Photovoltaic Module Recycling-Jereh New Energy

Mar 1, 2025 · Photovoltaic module disassembly, dismantling, and thermal desorption equipment can meet the needs of different site operations, effectively reducing labor costs and enhancing

Solar Module Glass Separator Equipment for PV Recycling

This equipment adopts automation technology to achieve automatic feeding, discharging, and separation of finished glass and panels, improving production efficiency and reducing labor costs.

2025 New Design PV Module Frame Junction Box Glass Separation

Key attributes type Recycling Plant Power 160 Kw core components motor, Engine, Other machinery test report Provided video outgoing-inspection Provided warranty 1.5 years material

Glass removing device for recycling photovoltaic modules

The invention discloses a glass dismantling device for recovering a photovoltaic module, which comprises a crushing unit, a stripping unit and a material collecting unit. On one hand, the

Waste photovoltaic panel glass separation equipment

Can electrostatic separation be used in silicon-based photovoltaic modules? The objective of this study is to evaluate the use of electrostatic separation technique to segregate some of the

A promising method for the liberation and separation of

Oct 15, 2023 · The separation of cover glass and solar cells is a prerequisite for recovering waste PV modules. Special liberation and separation processes need to be proposed for damaged

Complete recycling process for single-glass PV panels

Jun 2, 2025 · The complete recycling process for Single-Glass PV Module combines the synergistic operation of key equipment such as framing, mixing and de-glassing, shredding

Material Recovery from End-of-Life Solar Photovoltaic Module

May 6, 2023 · The expected life of photovoltaic (PV) modules is 10–20 years as solar modules degrades over the course of time. This degradation is mainly due to the water ingress, ultra

Recent progress in silicon photovoltaic module recycling

Dec 1, 2022 · The rapid deployment of solar photovoltaic (PV) technology around the world brings the ineluctable problem of disposing of and recycling decommissioned solar photovoltaic

Flash separation and recovery of each component from waste photovoltaic

Jun 1, 2025 · Abstract The recycling of end-of-life (EoL) photovoltaic modules represents the final step in the photovoltaic industry chain. A critical prerequisite for component separation and

6 FAQs about [Photovoltaic module glass separation equipment]

Are solar photovoltaic & collector modules becoming more popular in Southeast Asia?

Installations of solar photovoltaic (PV) and collector modules have been increasing significantly in the past ten years and continued to do so in many countries, especially in Southeast Asia.

Does microwave heating affect the delamination of solar panels?

well as testing the effect of microwave heating on the delamination of the remaining pa nel. silicon PV panel. The findings revealed that the temperature had a significant impact on the separation of glass shards from the solar panel's EVA layer. Microwaves' dielectric heat property involved heating electrically

Is microwave a good option for delaminating PV panels?

After heating the PV panel with a microwave, the results showed that removing the glass pane could be conveniently conducted easier than a non-heated panel by about 50-60% of the force. In summary, the microwave frequency appeared to be an attractive option for delaminating expired or damaged PV panels.

Can electrothermal heating be used to recycle c-Si solar panels?

TABLE 1. Benchmarking advantages and disadvantages of the thermal recycling process Electrothermal heating technology for recycling c-Si solar panels is currently being developed. The electrothermal technique, according to the study, would be able to restore glass and Si cells without causing harm. radiofrequency RF) electrothermal heating process.

How long will a solar PV panel last in Southeast Asia?

The project will be the most significant floating PV source in southeast Asia, having more than 1 million PV modules assembled. The approximate lifetime of a PV panel is about 25-30 years. Therefore, these solar PV wastes will be enormous at the end of life and may cause a big problem.

How to delaminate solar panels?

Previous research showed many methods to delaminate solar panels. Still, some recommended that thermal practice such as radiofrequency heating is simple and has a low environmental impact and low operating costs. Unfortunately, it has a high installation cost and is hard to develop into commercialization.

Update Information

- Photovoltaic glass separation and sorting equipment

- Photovoltaic module double glass insulation

- Tunisia double glass photovoltaic module price

- How much does the Hargeisa smart photovoltaic module equipment cost

- There are several types of photovoltaic module glass

- Tuvalu double glass photovoltaic module manufacturer

- N Djamena polycrystalline photovoltaic module glass

- Niamey standard photovoltaic module glass

- Energy storage container solar photovoltaic module factory photothermal equipment

- Bloemfontein double glass photovoltaic module manufacturer

- Photovoltaic glass in Cordoba Argentina

- What kind of vehicle is used to transport photovoltaic glass

- Photovoltaic glass thickness specifications

Solar Storage Container Market Growth

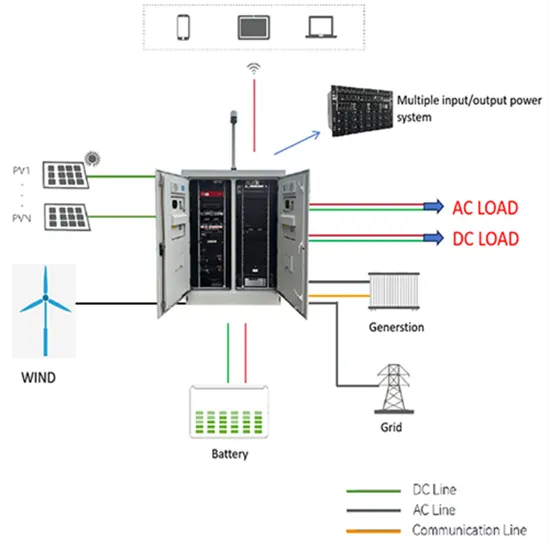

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.