PERC Cell Technology | Boviet Solar

By integrating the PERC (Passivated Emitter and Rear Cell) technology with the Shingled Emitter design, PERC SE cells achieve superior efficiency and reliability. PERC technology reduces

Comprehensive assessment of performance and reliability of PERC

Jul 15, 2025 · This study evaluates the performance and reliability of commercial PERC, TOPCon, and SHJ PV modules installed in Qatar''s desert climate for about three years. The modules

A complete guide on PERC solar panels | Just Solar

Jul 19, 2022 · PERC cells have an extra layer on the rear side of solar cells which enhances the internal reflectivity & electricity generation capabilities of the panel.

Life cycle assessment on PERC solar modules

Dec 1, 2018 · The PERC process has already been industrialized [5], and in 2016 the efficiency of a p-type monocrystalline cell using this technology achieved 20.6% [6]. However, efficiency

What you need to know about PERC solar cells

4 days ago · Conventional silicon photovoltaic (PV) cells have long been the standard in the solar industry. But as the technology matures and approaches hard efficiency limits, researchers

All About High Efficiency Solar Cells: PERC and

Aug 31, 2020 · Today, high efficiency solar cells that were once only seen in labs are installed on a global scale. PERC and Half Cut Cells are the most popular.

Solar Module Technology Comparison: N-type vs PERC vs

Feb 26, 2025 · Solar Module Technology Comparison: N-type vs PERC vs Thin-film I. Introduction Solar photovoltaic (PV) technology has evolved significantly over the years. Understanding the

Solar Module Technology Comparison: N-type vs PERC vs

Feb 26, 2025 · Understanding the differences between N-type, PERC, and Thin-film solar panels helps consumers, installers, and investors make informed decisions. Snippet paragraph: N

PERC solar cell technology guide: Benefits and drawbacks

Jun 2, 2025 · What is passivated emitter rear cell (PERC) solar technology? PERC is a high-efficiency solar technology. It adds a dielectric layer to silicon cells. This layer reflects light and

Technology selection for US cell manufacturers –

May 12, 2025 · CEA''s Martin Meyers considers the pros and cons of the different PV cell technology options for manufacturers starting production in the US.

Life cycle assessment on PERC solar modules

Aug 1, 2021 · With the pursuit of high photoelectric conversion efficiency in the photovoltaic market, passivated emitter and rear cell (PERC) modules has become the new market

6 FAQs about [PV Module Perc]

What is a PERC solar cell?

If you have any questions, please contact us. Conventional silicon photovoltaic (PV) cells have long been the standard in the solar industry. But as the technology matures and approaches hard efficiency limits, researchers and manufacturers have started to embrace a relative newcomer — the Passivated Emitter and Rear Contact (PERC) solar cell.

How do PERC solar panels work?

To understand how PERC solar panels work, it’s essential to understand the common issues you may encounter with a standard solar cell. First, traditional crystalline silicon solar cells generate power when light hits a silicon layer, loosening electrons and forcing them to flow through a wire.

What are PERC cells?

As an efficient solar cell, PERC cells are one of the important trends in the development of the solar cell industry. With the increasing demand for renewable energy, the market demand for solar cells is also constantly growing. The emergence of PERC cells has greatly improved the efficiency and performance of solar cells.

Why should a solar PV installer use perc?

As a result, solar PV installers are able to save time and reduce costs when using the newer PERC standard. This is because fewer panels are needed to achieve the same solar power output. Using fewer panels also helps to reduce the amount of racking, wiring, and MLPE devices needed to connect everything together.

What are Topcon and PERC solar cells?

At the forefront of this growth are two competing solar cell technologies: TOPCon and PERC. TOPCon (Tunnel Oxide Passivated Contact) and PERC (Passivated Emitter and Rear Cell) are the latest advancements in solar cell design, offering improved efficiency and performance.

How can PERC improve photovoltaic module conversion efficiency?

The PERC structure can break through the physical efficiency achieved by traditional photovoltaic cells and enable photovoltaic module manufacturers to improve module conversion efficiency.

Update Information

- EU export PV module prices

- Kosovo PV Flexible Module Project

- Kyrgyzstan downgrades PV module exports

- Indian PV module prices

- Global PV Module Prices in Pakistan

- Indian PV module selling prices

- The first heterojunction module with parity with PERC

- Castries PV module wholesale prices

- Huawei Somaliland PV Module Project

- Huawei Uruguay PV Module Project

- Outdoor power waterproof module

- Dili Solar Photovoltaic Module Factory

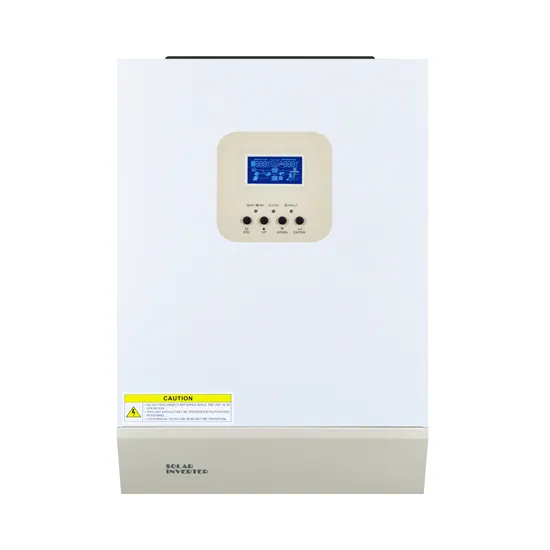

- Igbt module to 220v inverter

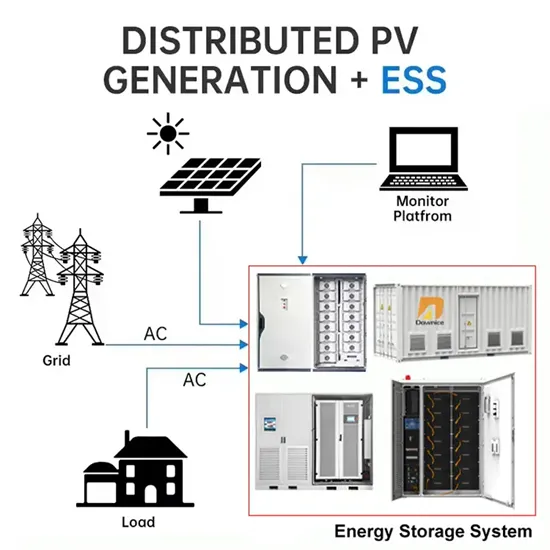

Solar Storage Container Market Growth

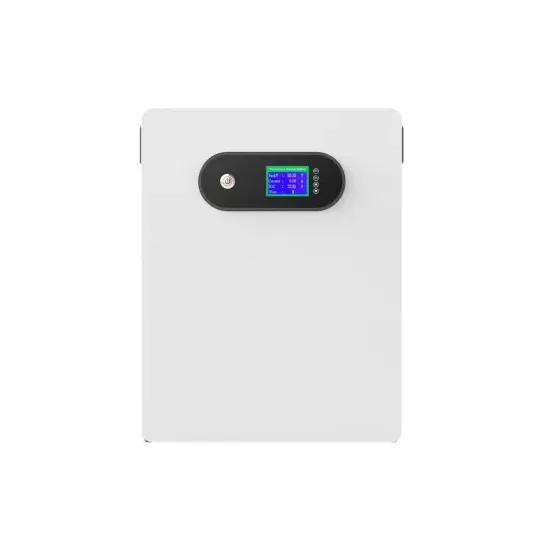

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.