LCOE analysis of PERC, TOPCon and HJT

Oct 20, 2022 · In this paper, we compare the LCOE of TOPCon and HJT with PERC in difer-ent scenarios as follows. We chose five project locations with typical climate. PV module

Cost‐efficiency potential of solar energy on a global scale:

Jul 9, 2024 · In this study, we present the first global LCOE estimates for a PERC module (20% cell efficiency) and a SHJ module (23% cell efficiency), which have been derived by (i)

WHAT ARE MONO PERC SOLAR PANELS?

Jun 20, 2024 · Lower degradation: TOPCon modules have a lower power degradation during the first year and over the 25 years of use, compared to PERC solar PV modules. Hence, they will

Photovoltaic PERC, HJT, TopCon Battery Market

May 4, 2025 · Manufacturers counter cost barriers through innovation – Jinko Solar reduced TopCon''s silver consumption to 13.8mg/W in 2023, narrowing the cost gap with PERC to

THE TECHNOLOGY RESOURCE FOR PV PROFESSIONALS

May 9, 2023 · First Solar secures module supply deals with Intersect Power, National Grid Renewables itional 4.9GWdc of its thin-film PV modules. The transaction means that Intersect

Cost-efficiency potential of solar energy on a global scale

Jul 9, 2024 · Levelized cost of electricity (LCOE) is a crucial metric for assessing the socio-economic cost-efficiency potential of various energy sources including solar photovoltaics.

Solving all bottlenecks for silicon heterojunction

May 21, 2024 · Silicon heterojunction (SHJ) solar cells are the archetypes of ''full-surface passivating contact'' solar cells; such contacts are required in order to achieve typical open

What are heterojunction technology (HJT) solar

Nov 4, 2019 · The c-Si component brought increased efficiency stability while the a-Si side included the increased light absorption. Heterojunction technology

Solving all bottlenecks for silicon heterojunction

Mar 5, 2019 · With a recent spate of new solar cell records announced for PERC-based architectures pushing conversion efficiencies past 24%, it is a good

Early degradation of silicon heterojunction PV modules

We present our latest findings on the early degradation of photovoltaic (PV) silicon heterojunction (HJT) modules installed in harsh desert climates for about two and half years. The results are

All About HJT – The Secret of Heterojunction Solar Cell

Jan 2, 2025 · Heterojunction (HJT) technology is transforming the solar industry with its high-efficiency and superior long-term performance. But what makes it stand out from technologies

Heterojunction Solar Technology

Jun 18, 2024 · PERC, in general, is no longer able to support module eficiencies above 21.6%. Almost all of the leading cell/module makers'' commercial modules with eficiencies above

Cost‐efficiency potential of solar energy on a global scale

Jul 9, 2024 · Abstract Levelized cost of electricity (LCOE) is a crucial metric for assessing the socio‐economic cost‐efficiency potential of various energy sources including solar

Long‐term performance and reliability of silicon heterojunction

Mar 2, 2023 · The high-efficiency silicon heterojunction (SHJ) technology is now perceived mature enough to enter the Giga-Watt manufacturing scale with several players around the globe. The

Industrial implementation of bifacial PERC+ solar cells

May 21, 2024 · The first small-scale outdoor installations have confirmed an increase in energy yield relative to monofacial PERC modules of between 13 and 22%.

Early degradation of silicon heterojunction PV modules

In contrast to the PERC PV modules with thermoplastic polyolefin (TPO) and polyolefin elastomer (POE) encapsulants, HJT modules with TPO encapsulants showed distinct UVF patterns

Cost‐efficiency potential of solar energy on a global

Jul 9, 2024 · As high-efficiency Si solar cell modules, on the other hands, two types of solar cells have been produced widely: i.e., a passivated emit-ter and rear cell (PERC)17–19and silicon

"New Green Engine" Jinergy in the Energy Expo 2018 with

As the No. 1 PV module manufacturer in Shanxi, Jinergy showcased its three high-end technology products — high efficiency polycrystalline module, high efficiency monocrystalline PERC

6 FAQs about [The first heterojunction module with parity with PERC]

What is the difference between PERC and HJT cells?

The HJT cells are processed at < 250 °C which saves a lot of energy during manufacturing cells. The number of steps required to manufacture these cells are halved compared to the industry standard PERC.

What is silicon heterojunction (SHJ) technology?

This perspective focuses on the latter PC technology, more commonly known as silicon heterojunction (SHJ) technology, which achieved the highest power conversion efficiency to date for a single-junction c-Si solar cell. Moreover, the SHJ technology has been utilized in realizing world record perovskite/c-Si tandem solar cells.

What is a tunnel oxide passivated contact (Topcon) & heterojunction (HJT)?

New technologies including tunnel oxide passivated contact (TOPCon) and heterojunction (HJT) provide chances Solar resources and annual average temperatures of Golmud, Berlin, Jinan, Dallas and Dubai. of lowering the levelised cost of energy (LCOE), even based on the fact that the price of n-type modules is currently higher than PERC.

Is HJT better than PERC?

The PR of HJT based plant is 4.7%abs greater than the PERC based plant which clearly shows the advantages of utilizing HJT technology. With such advantages, HJT stands out tall when compared to its competitors in almost all the fields. Figure 7: Comparison between HJT & PERC. Where is the world going ahead with HJT?

Which is better perc or HJT based power plant?

Next, with HJT having better surface passivation & low light performance along with lowest initial degradation, we find that the specific energy output of HJT based power plant stands at 1922 kWh/kWp/year which is around 6% higher than PERC based power plants.

What is the cost difference between SHJ and PERC?

Overall, the cost difference between SHJ and PERC for typical production efficiencies (∼22.5% for SHJ and ∼21.5% for mono-PERC) currently stands at ∼4.67¢/Wp. This gap reduces to ∼3.6¢/Wp when considering practical PCE limits for both device technologies (26% for SHJ and 24% for mono-PERC).

Update Information

- Heterojunction modules are on par with PERC modules

- PV Module Perc

- Photovoltaic module export specifications

- Photovoltaic module cost price

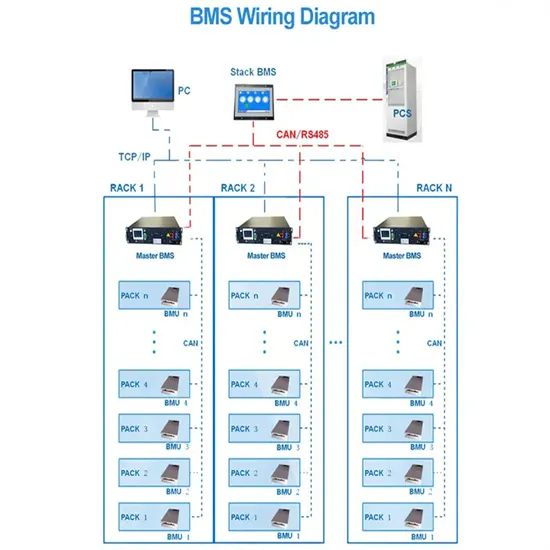

- Serbia Energy Storage Module Equipment Company

- Base station equipment power module

- Lebanon standard photovoltaic module panels

- Photovoltaic module companies exporting to Western Europe

- Chile photovoltaic module project

- Double-glass module field capacity

- Solomon Islands supercapacitor module manufacturer

- Cylindrical lithium battery module price

- Southern Europe Double Glass Photovoltaic Module Company

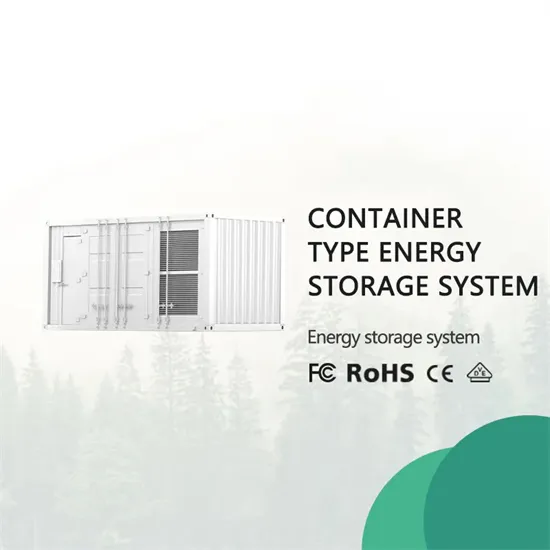

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.