How to reduce system cost in a three-phase IGBT-based

Aug 1, 2023 · Most three-phase inverters use insulated gate bipolar transistors (IGBTs) in applications like variable-frequency drives, uninterruptible power supplies, solar inverters and

IGBT 模块 – Mouser

Aug 6, 2025 · IGBT模块(IGBT Module),应有尽有。 Mouser Electronics(贸泽电子)是众多IGBT模块原厂的授权代理商,提供多家业界知名制造商的IGBT模块,包括Infineon

How to Design Power Converters with IGBTs

Mar 17, 2020 · An electrothermal analysis of a triple IGBT module designed using Ansys Icepak (left) and Ansys Q3D Extractor (right) These devices transform electrical power from one form

How to Use IGBT in Inverter: The Right Way to Handle High

IGBTs (Insulated Gate Bipolar Transistors) are key components in modern inverters, enabling efficient switching of high voltages and currents. This guide explains the best practices for

Design and Control of a Three-Phase T-Type Inverter using

Nov 17, 2020 · This paper proposes the design and implementation of a 15kW three-phase T-type inverter. Fuji Electric''s new generation IGBT module (V series) using RB-IGBT technology is

Design Considerations for using IGBT modules in

Apr 11, 2017 · Introduction This work is designed to assist the IGBT module selection process as well as offer guidance through the inverter/motor drive design and evaluation process. To build

Choose Your IGBTs Correctly for Solar Inverter Applications

May 18, 2025 · As can be seen in the table, a standard-speed IGBT has the lowest VCEON, but the slowest fall time compared to the other two fast and ultrafast planar IGBTs. The fourth

Integrated IGBT Modules Simplify Power Management

Aug 1, 2023 · Each phase of a three-phase inverter uses a high- and low-side IGBT to apply an alternating positive and negative voltage to the motor coils. Pulse-width modulation (PWM) to

The Intelligent Power Module Concept for Motor Drive

Jun 16, 2025 · The Intelligent Power Module Concept for Motor Drive Inverters Designers of inverters for small AC motors in consumer and general purpose industrial applications are

nithinmathewjoji/LiteWave-full-sine-wav-inverter

A compact yet powerful single-board inverter designed for portability and efficiency. Operating at 12V DC and converting to a stable 220V AC at 50Hz, it features a sine wave output With a

Update Information

- 1 point 5 degrees of electricity inverter into 220v

- Afghanistan lithium battery inverter 12v to 220v

- 72v inverter reduces 12v to 220v

- The inverter can support 220v

- Inverter 22v to 220v

- 66v to 220v inverter

- 220v inverter industrial grade

- Sunshine 5kw 220v photovoltaic inverter

- Inverter has 36V to 220V

- Costa Rica 48v to 220v inverter

- Inverter 220V charging

- Ghana inverter 220V assembly

- Wholesale 220v solar inverter in Mombasa

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

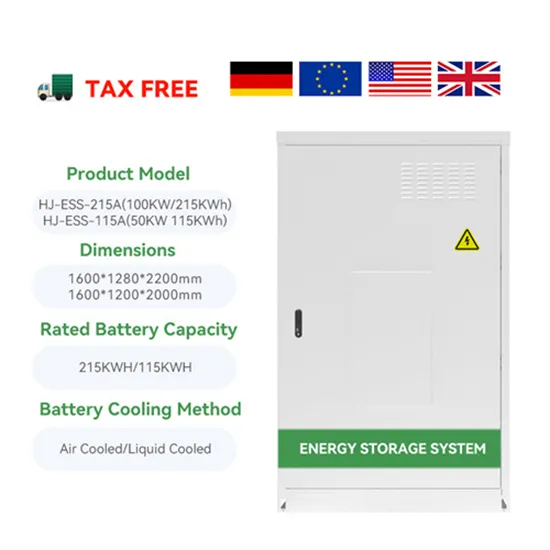

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.