A High Performance High Frequency Inverter Architecture

Oct 14, 2021 · In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

High-frequency inverter with phase-shifted PWM and load

The authors describe a control scheme incorporated in the voltage-fed full-bridge series resonant high-frequency inverter using static induction high power transistors (SITs), which is based on

Continuous high-performance drive of rotary traveling-wave ultrasonic

Feb 1, 2015 · The key novelty relates to the integration of water cooling to rotary traveling-wave ultrasonic motor (RTUSM), hence opening up the potential use of RTUSM to the continuous

Forced Air-Cooling Thermal Design Methodology for High-Density, High

Nov 29, 2022 · Due to increased loss per unit volume in power transformers when operating at higher frequency, the increase in cooling system size can outweigh high-frequency transformer

Frequency Converters MEDIUM VOLTAGE — WATER

Jul 11, 2023 · 0 to 12700 kW 3.3 to 4.16 kV INGEDRIVETM MV100 Water The most reliable, versatile medium vol. age family for applications with high power demands. The

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

Liquid Cooling System for a High Power, Medium

Oct 6, 2023 · While more efficient, liquid cooling requires more maintenance and has higher upfront costs. Water-cooling systems have become famous for regulating thermal loads as

Ideei High Performance AC Drive, Frequency Converter, Commercial Water

5 days ago · The LX3300 series inverter is based on a DSP control system, adopts vector control technology, and is combined with various protection methods. It can be used for asynchronous

Silicon carbide based traction inverter cooling in electric

Dec 1, 2023 · Four-wheel drive battery electric vehicles (4WD BEVs) faces issues due to complex water cooling system of the standard silicon based inverter systems for the rear and front

Research and development of FGI super power water cooled high

Dec 24, 2024 · In addition to its impressive efficiency, the FGI super power water-cooled high voltage frequency inverter is also designed for maximum reliability and durability. By

Solar Pump Inverters, Solar Pump Drives | inverter

A high-performance 0.75kW solar water pump inverter is on sale, with an AC 2.1A output current at 3-phase 380V and a DC voltage range of (280V, 750V). The pump inverter with an output

Inverter, Solar Inverter, Home Power Inverter | inverter

High quality and reasonable price 300 watt pure sine wave inverter for sale, 12 volt DC, AC output can select 100V, 110V, 120V, 220V, 230V and 240V, output frequency 50Hz or 60Hz. Power

"FRENIC4800VM5," a Water-Cooled High Capacity, High

Sep 23, 2017 · Through repeated analysis and testing, we aimed to improve cooling performance and reliability through water cooling technology and as a result released the

Application of variable frequency drives in cooling system

Dec 29, 2023 · In the cooling system, the application of frequency converter can adjust the operating speed of fans, water pumps and other equipment to adapt to different working

High Frequency MOSFET Based Three Phase Inverter For

May 31, 2016 · This is to certify that the thesis titled High Frequency MOSFET Based Three Phase Inverter For Drive Application Using TI''s DSC, submitted by Jagdish singh, to the Indian

6 FAQs about [High frequency inverter with water cooling]

What is hvvf water cooling medium voltage drives?

DOWNLOAD CATALOG NC HVVF Water Cooling Medium Voltage Drives is a voltage source inverter based on IGBT and cell series multi-level PWM technology. Characterized by low harmonics and high efficiency. Achieving output voltage of up to 18kV with perfect sinusoidal waveform and directly driving almost all MV motors without a step-up transformer.

What is hvvf7000 water cooling MV AC drive?

HVVF7000 water cooling MV AC drives, used for soft start and speed adjustment of compressors, more reference in oil and gas, pipelines, know more stories from Shanghai Nancal Electric Co.,Ltd. .

What is a liquid cooled VFD?

A liquid cooled VFD utilizes the increased heat dissipation capabilities of liquid over air. KEB's liquid-cooled drives provide a VFD solution for applications that would not be possible, or severely limited, if the only cooling option was air cooling.

What are the benefits of using a VFD with a liquid cooled heatsink?

Using a VFD with a liquid cooled heatsink may allow for a physically smaller system and may also eliminate the need for external cooling devices. This can be achieved if a suitable cooling medium is available.

What is a better cooling option for high-power applications?

For high-power applications, liquid cooling is a better option than air cooling. Utilizing the increased heat dissipation capabilities of liquid over air, the KEB liquid-cooled drives provide a VFD solution for applications that would not be possible, or severely limited, if the only cooling option was air cooling.

Can I use a liquid cooled heatsink with KEB VFDs?

KEB's liquid cooled VFDs are designed to work with liquid cooled heatsinks. To help reduce condensation issues in high humidity applications, KEB has developed specific software features for use with these drives, including heatsink temperature control by external valve control.

Update Information

- High frequency inverter with water cooling

- Yemen high frequency inverter price

- Is a pure wave inverter a high frequency

- Which is better high frequency or low frequency inverter

- North Africa High Frequency Inverter Brand Ranking

- Benefits of high frequency inverter

- NFA inverter is a high frequency machine

- Inverter Type High Frequency Power Frequency

- 300k high frequency inverter

- Korean high frequency inverter installation

- 5kW high frequency inverter

- High frequency inverter produces sine wave

- South Sudan High Frequency Communication Inverter

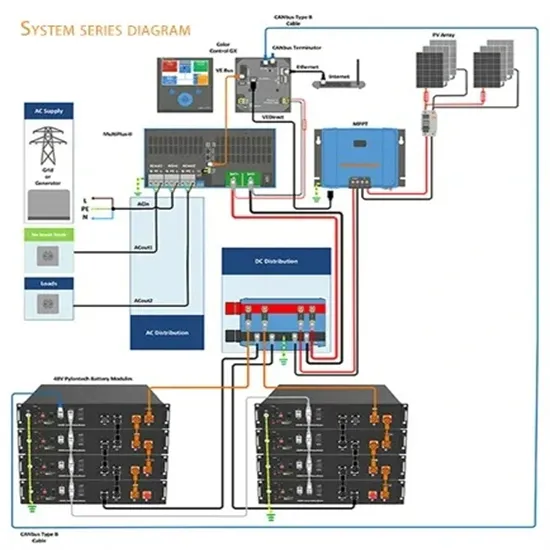

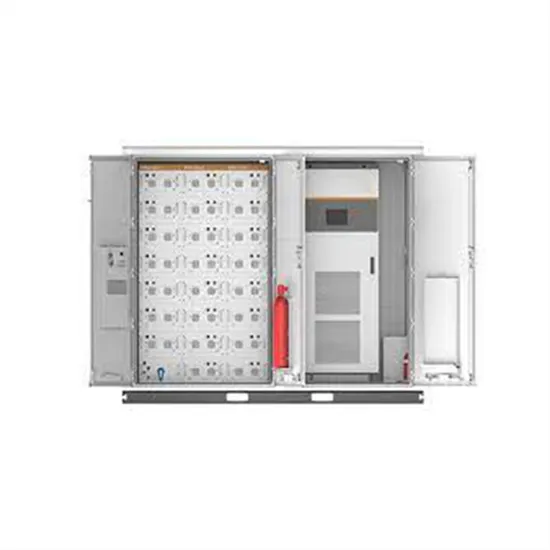

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.