Kinetics study on separation of cadmium from tellurium in

Oct 17, 2005 · Cadmium (Cd) and tellurium (Te) are the major materials used in manufacturing cadmium telluride (CdTe) modules for photovoltaic (PV) cells. However, the content of these

Effect of the cadmium ion source on the structural and

Jun 1, 1999 · Abstract The chemical bath deposition (CBD) technique has been successfully used to deposit cadmium sulphide from cadmium chloride and cadmium acetate as the cadmium ion

High-efficiency cadmium-free Cu (In,Ga)Se

Apr 20, 2025 · Abstract Cu (In,Ga)Se 2 (CIGSe) solar cells have significantly progressed in associated flexible photovoltaic technologies. Recently, ultra-thin glass (UTG) has been

Cadmium Telluride Power Glass Transforms An Existing

Cadmium telluride power glass is an energy based building material that is versatile, green, energy-saving, and innovative. It has strong power generation capacity and low temperature

A systematic study on chemically deposited cadmium sulfide (CdS

Jun 3, 2020 · Introduction Thin-film semiconductor plays a functional role in the fabrication of photovoltaic devices, optoelectronic devices, magnetic devices, and photonic transducers due

End of life management of crystalline silicon and cadmium

Oct 1, 2023 · The rapid global adoption of solar photovoltaic (PV) modules created the issue of recycling and disposal at their end of life. Several PV modules inst

Sustainable Solar: Recycling Photovoltaic Panels for a

Feb 5, 2025 · The fast expansion of solar photovoltaic (PV) technology has placed it as a prominent participant in the worldwide transition towards renewable energy but the rising

Preparation and characterization of glass/FTO/CdS/ED

Oct 2, 2022 · Inorganic thin-film photovoltaic (PV) cells have been fabricated using the n -type cadmium sulfide (CdS) window and p -type cadmium telluride (CdTe) absorber layers. This

Cadmium telluride power glass: future vegetable greenhouses

Fundamentals of 1. cadmium telluride power generation glass Cadmium telluride power generation glass, as the name suggests, is a special glass that can simultaneously realize

Elaboration and characterization of cadmium sulfide (CdS)

Jan 1, 2022 · The chemical bath deposition technique has found great success in recent years as it has become an integral part of the industrial process for the preparation of large-scale solar

Emerging innovations in solar photovoltaic (PV)

Light-absorbing materials play a pivotal role in solar PV technologies. Photovoltaic cells convert sunlight into electricity using semiconducting materials that exhibit the photovoltaic effect. Key

CdTe-based thin film photovoltaics: Recent advances,

Jun 15, 2023 · Cadmium telluride (CdTe)-based cells have emerged as the leading commercialized thin film photovoltaic technology and has intrinsically better temperature

Comparative study of cadmium telluride solar cell

Jul 23, 2024 · Cadmium telluride (CdTe) has gained much interest from both academia and industry due to its direct bandgap, large absorption coefficient, high charge carrier mobility and

Effect of Ag-doping on the structural, optical, electrical and

Jan 24, 2020 · Effect of Ag-doping on the structural, optical, electrical and photovoltaic properties of thermally evaporated Cadmium Selenide thin films

Extraction and Separation of Cd and Te from Cadmium

Aug 11, 2006 · The leaching experiments were carried out at ambient temperature in a tumbling machine. We assessed the efficiency of two oxidative-leaching procedures in extracting

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Apr 3, 2025 · Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Cadmium telluride (CdTe) photovoltaics

Aug 27, 2019 · Cadmium telluride (CdTe) photovoltaics or also called Cadmium telluride solar cell is a kind of photovoltaic (PV) technology that can produce electricity from sunlight using a thin

Integrated semi-transparent cadmium telluride photovoltaic glazing

Dec 1, 2018 · When integrating photovoltaics into building windows, the photovoltaic glazing modules inhibit the function that glass performs, with the additional function of energy

Extraction and separation of Cd and Te from cadmium

Feb 17, 2006 · The extraction and separation of cadmium, tellurium, and copper from CdTe PV module scrap was investigated. Several leaching technologies were assessed and the

Opportunities for Recycling PV Glass and Coal Fly Ash into

Dec 27, 2022 · This work shows the development and characterization of two zeolite structures by recycling PV glass and coal fly ash for the removal of cadmium, copper, and lead from

Embodied energy and carbon from the manufacture of cadmium

Jul 20, 2022 · Looking beyond the traditional cost and efficiency metrics of photovoltaics (PV), this work evaluates the impact of embodied energy, embodied carbon,

6 FAQs about [Cadmium ion photovoltaic glass]

How are inorganic thin-film photovoltaic (PV) cells fabricated?

Inorganic thin-film photovoltaic (PV) cells have been fabricated using the n -type cadmium sulfide (CdS) window and p -type cadmium telluride (CdTe) absorber layers. This work combines significant literature with new results from a research programme including electroplated and chemical bath deposited CdTe and CdS, respectively.

What is thin film photovoltaic (PV)?

Introduction Thin film photovoltaic (PV) technologies often utilize monolithic integration to combine cells into modules. This is an approach whereby thin, electronically-active layers are deposited onto inexpensive substrates (e.g. glass) and then interconnected cells are formed by subsequent back contact processes and scribing.

Are CdTe solar modules the highest production thin film photovoltaic technology?

Herein we have reviewed the developments in the cell technology that has enabled CdTe solar modules to emerge as the highest-production thin film photovoltaic technology.

What is cadmium telluride (CdTe)?

Cadmium telluride (CdTe) thin-film PV modules are the primary thin film product on the global market, with more than 30 GW peak (GWp) generating capacity representing many millions of modules installed worldwide, primarily in utility-scale power plants in the US.

How do different types of PV modules affect a glazing façade?

When integrating different types of PV modules into a building window or glazing façade, the variation of thermo-optical (e.g. emissivity, solar and visible) transmittance of the glazing material will affect the fraction of absorbed, transmitted and re-radiated solar radiation, as well as the amount of penetrating daylight.

Are CD and Te photovoltaics a good use?

In this sense, the use of Cd and Te as CdTe photovoltaics represents a very good use for these derivatives of primary metal production that would otherwise be released to the environment or require managed sequestration.

Update Information

- Cadmium telluride photovoltaic glass

- Phnom Penh non-standard photovoltaic curtain wall glass components cadmium telluride

- Photovoltaic 2 5mm glass production

- Special-shaped photovoltaic glass curtain wall

- Photovoltaic tempered glass transportation standards

- Photovoltaic glass in Cordoba Argentina

- Solar Photovoltaic Glass Separation Plant

- Russia St Petersburg double glass photovoltaic modules

- EK Photovoltaic Glass Transportation

- Glass greenhouse with photovoltaic

- Residual value of photovoltaic glass

- Belarusian glass photovoltaic power generation

- Curtain wall photovoltaic glass production

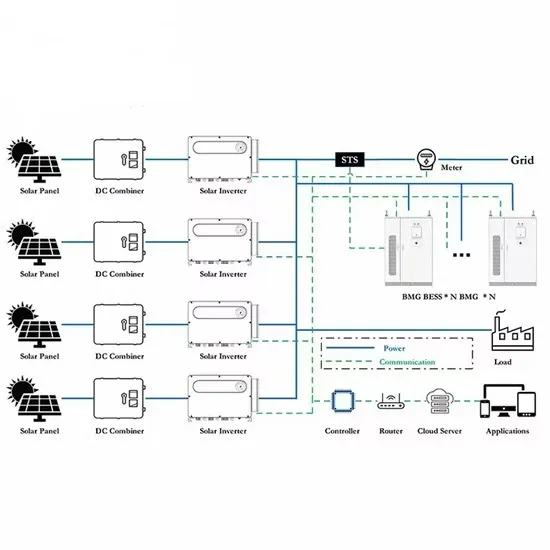

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.