BYD''s Battery Revolution — No Lithium, No

Apr 12, 2025 · BYD is shaking up the electric vehicle world with its next-gen Blade Battery—completely lithium-free, ultra-fast charging, and safer than ever. By

基于并联蛇形流道的动力电池冷媒直冷热管理系统研

Mar 28, 2024 · 关键词: 动力电池, 热管理, 冷媒直冷, 并联蛇形流道, 均温性 Abstract: For the thermal management system of a power battery using direct

Unpacking the Technical Specifications of BYD''s Gen 2 Blade Battery

Feb 7, 2025 · BYD''s Blade battery technology has revolutionized electric vehicle manufacturing by making it possible to shrink battery packs while increasing driving range, prompting many EV

byd-blade-battery-specifications-3.2V/420Ah LiFePO4 BYD Blade

Jun 30, 2025 · Key Features: advantage of LiFePO4 BYD Blade Cell(3.2V/420Ah) : 1. Increased battery energy density: The blade battery cancels the module design and reduces

Liquid Cooling Battery Cabinet: Modern BESS Technology

Advancements in Battery Cabinet Cooling Technology Historically, battery thermal management relied on simpler methods like air cooling, where fans circulate ambient air to dissipate heat.

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

How Battery Cabinet Cooling Technology Works The core principle behind Battery Cabinet Cooling Technology is its superior heat transfer capability. In a typical setup, a dielectric

刀片电池直冷冷却热管理系统设计与优化

结果表明,本文所设计的直冷式电池热管理系统可以将电池包的最高温度控制在20~40℃以内,且各单体电池温差小于5℃,满足散热目标。 通过对比不同结构的直冷板的最高温度变化情况,得到蛇

Exploring Liquid Cooling Battery Cabinet Technology

Innovations in Battery Cabinet Cooling Technology The sophistication of modern Battery Cabinet Cooling Technology is a testament to precision engineering. These are not simply add-on

A thermal perspective on battery safety | Nature Reviews Clean Technology

May 28, 2025 · Excessive heat generation in batteries can result in thermal runaway and fires incidents. This Perspective examines thermal runaway characteristics and propagation and

Investigation on High-Temperature-Uniformity Direct

Jun 21, 2025 · Abstract Direct cooling technology is regarded as a promising method for battery thermal management owing to its high heat transfer eficiency. However, the overheating

Research on fast-charging battery thermal management

Jul 20, 2023 · Refrigerant direct cooling technology is a new type of power battery phase change cooling system, which uses the refrigerant in automotive air conditioners as a cooling medium

Performance Study of the Direct Cooling Thermal

Sep 23, 2024 · The blade battery offers a longer lifespan, enhanced safety, and improved space utilization and battery pack integration. However, its heat generation distribut

Exploring Liquid Cooling Battery Cabinet Technology

To ensure reliability and maximize performance, these systems must operate under optimal conditions, with thermal management being a key factor. A pivotal innovation addressing this

Estimation of temperature field for blade battery based on

Dec 15, 2024 · Blade batteries exhibit significant temperature non-uniformity. Sinusoidal pulse excitation is widely used in the pre-heating process of commercial lithium batteries due to its

Electric Vehicle Energy Storage: How Blade Batteries Are

Nov 16, 2023 · Enter the blade battery – the razor-sharp solution that''s slicing through traditional lithium-ion limitations. By 2025, over 60% of new EVs in China are expected to adopt this

Type of the Paper (Article

Jul 5, 2025 · Blade battery technology was developed by BYD, a leading Chinese automotive and green energy company [6]. It represents a new approach to lithium-ion batteries, designed

Study on battery direct-cooling coupled with air conditioner

Oct 15, 2023 · The direct-cooling battery thermal management system connects the battery cooling circuit directly to the vehicle air conditioning system, and refrigerant flows directly into

Liquid Cooling: Efficiency in Battery Storage

The Superiority of Liquid Cooled Battery Systems Compared to conventional cooling methods, Liquid Cooled Battery Systems offer a significant leap forward in thermal performance. This

Liquid Cooling Battery Cabinet Efficiency & Design

Innovations in Battery Cabinet Cooling Technology The advancement of Battery Cabinet Cooling Technology is a direct response to the growing demands of the renewable energy sector and

What is Blade Battery? New EV Battery Technology

Feb 27, 2024 · In addition, the battery pack uses a wide-temperature efficient heat pump system and direct cooling and heating technology, which enables rapid

6 FAQs about [Blade battery cabinet direct heating and cooling technology]

What is BYD blade battery?

What is Blade Battery? BYD has been a pioneering name in the battery industry for more than 29 years. The driving force of each of our electric cars is the innovative BYD Blade Battery. Recognised as one of the world’s safest EV batteries, our battery has passed rigorous safety tests and is designed to maximise strength, range and life cycle.

How does a direct-cooling battery thermal management system work?

In vehicles, the direct-cooling battery thermal management system usually connects the battery cooling plates parallel to the vehicle air conditioning evaporator, forming a cooling system with two evaporators with different cooling requirements.

How do evaporator and battery temperature control work?

By regulating the VOV on the evaporator side and the VOV on the cooling plate side of the battery under different conditions, the cabin's and the battery's temperatures are stabilized around their temperature control targets. Fig. 5. Uneven distribution of cooling capacity.

Can a refrigerant-based battery thermal management system be used for electric vehicles?

A novel electric vehicle thermal management system based on cooling and heating of batteries by refrigerant Energy Convers. Manag., 237 ( 2021), Article 114145 System simulation on refrigerant-based battery thermal management technology for electric vehicles Energy Convers. Manag., 203 ( 2020), Article 112176 J. Electrochem.

Why is air-cooling battery thermal management system bad?

Because of the miniature thermal conductivity of air, the air-cooling battery thermal management system has low heat transfer efficiency and insufficient cooling capacity, so it cannot meet the cooling requirements of the battery when the battery is operating at high power.

How long does a blade battery last?

Blade Battery has a long battery life with over 5000 charge and discharge cycles. With a range of EV and PHEV to choose from, whether that’s fully electric or hybrid options, new energy vehicles give drivers the option to reduce their carbon footprint in a way that suits their lifestyle.

Update Information

- Battery cabinet direct cooling system volume

- Energy storage cabinet battery 5MWH liquid cooling production

- Liquid Cooling Battery Cabinet Production

- Battery cabinet liquid cooling price

- New Energy Natural Cooling Battery Cabinet

- New energy battery cabinet fan cooling principle

- New Energy Battery Cabinet Cooling Method

- Technology battery cabinet

- What technology does the energy storage cabinet battery use

- Battery Cabinet Protection Technology Principle Base Station

- Blade battery cabinet production

- Lome outdoor communication battery cabinet factory direct sales shop

- Minsk DC screen battery cabinet manufacturer direct sales

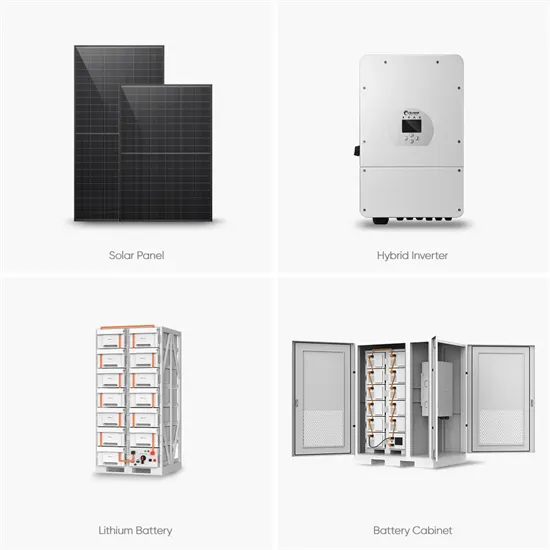

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.