Byd blade Battery: 51.2V140Ah New Energy Battery Market

Apr 8, 2025 · In order to maintain its market leading position and continue to meet consumer demand, BYD will continue to increase R&D investment and innovation in blade battery

BYD Blade Cell Technologies-3.2V/150Ah C104F (LiFePO4 BYD Blade

Dec 10, 2024 · Technical features of BYD blade batteries : The BYD blade battery adopts the CTP (Cell To Pack) design concept. The battery cells are directly installed in the battery pack

Electric Car Energy Storage: How Blade Mill Technology is

Jun 7, 2019 · Converting traditional blade mill facilities for battery production is like teaching a diesel mechanic to code – possible, but requiring serious upskilling. The payoff?

What are the energy storage blade battery factories?

Mar 7, 2024 · This design significantly increases energy density while reducing the overall footprint of the battery packs. Unlike traditional batteries, which often suffer from bulkiness and

Blade battery module production process

What makes BYD a module-free battery pack? With cell-to-pack technology,BYD designed the module-free battery pack using the Blade Cell. The geometry of the Blade Cell is a key to the

byd-blade-battery-specifications-3.2V/420Ah LiFePO4 BYD Blade

Jun 30, 2025 · Key Features: advantage of LiFePO4 BYD Blade Cell(3.2V/420Ah) : 1. Increased battery energy density: The blade battery cancels the module design and reduces

A Glimpse into BYD''s Blade Battery Factory in Chongqing

Jun 4, 2020 · Located in the city''s Bishan District, the factory is currently the only production base for the Blade Battery. It possesses a highly demanding production environment and much of

Blade battery production and processing equipment

company provides full-process equipment solutions and services for the power battery, energy storage battery, and consumer battery industries, and provides global battery manufacturers

BYD Blade Battery: Advantages and Disadvantages

Jul 24, 2025 · Through the analysis of blade batteries, BYD blade batteries play more of a connecting role in the current power battery industry. Although blade batteries still have many

Blade battery production line process flow

Batteries Step by Step: The Li-Ion Cell Production Process The production of lithium-ion (Li-ion) batteries is a complex process that involves several key steps, each crucial for ensuring the

BYD Blade Battery: Leading a New Era in Lithium Iron

Aug 5, 2025 · BYD Blade Battery: Leading a New Era in Lithium Iron Phosphate Batteries In the world of new energy vehicles, battery technology innovation has always been the driving force

BYD 3.2V/150Ah C104F (LiFePO4 BYD Blade Cell)

Mar 26, 2025 · Technical features of BYD blade batteries : The BYD blade battery adopts the CTP (Cell To Pack) design concept. The battery cells are

Scalability Challenges in Mass Production of Blade Battery

Aug 8, 2025 · The blade battery, introduced by BYD in 2020, represents a significant evolution in lithium-ion battery technology. This innovative design addresses key challenges in electric

What Makes BYD''s Blade Battery 2.0 a Game-Changer for EVs?

Apr 11, 2025 · BYD''s Blade Battery 2.0 enhances electric vehicle (EV) performance with improved energy density, thermal stability, and safety. Using lithium iron phosphate (LFP) chemistry and

BYD 3.2V/245.5Ah C115F (LiFePO4 Blade Cell )-The BYD Blade

Jun 23, 2025 · The shape of the blade battery is a flat rectangle, which not only improves the heat dissipation effect, but also demonstrates its high safety and strength through needle tests and

A Glimpse into BYD''s Blade Battery Factory in Chongqing

Jun 8, 2020 · Located in the city''s Bishan District, the factory is currently the only production base for the Blade Battery. It possesses a highly demanding production environment and much of

How BYD''s Blade Battery is Reshaping the Future of Electric

Jul 30, 2025 · Currently, BYD''s Blade Battery is available in its models like the BYD Han and Tang. When considering an EV with a Blade Battery, compare the following features: Range:

6 FAQs about [Blade battery cabinet production]

Where is BYD blade battery made?

Located in the city’s Bishan District, the factory is currently the only production base for the Blade Battery. It possesses a highly demanding production environment and much of BYD's self-developed Blade Battery production equipment. The factory has a total investment of 10 billion yuan with an annual production capacity of 20GWH.

Why do we need blade batteries?

Blade batteries cannot achieve higher energy density in battery materials, but they have made breakthroughs in battery system integration. This solves the shortcomings of short battery life of lithium iron phosphate batteries. This is the background for the birth of blade batteries. Part 3. BYD blade battery specifications Part 4.

What are the advantages and disadvantages of blade batteries?

Another advantage of blade batteries is that they have good heat dissipation performance. We all know that batteries are particularly sensitive to temperature, which is also the main reason that limits battery fast charging time. Therefore, heat dissipation is a very important indicator for battery cells.

How a blade battery is made?

There are generally two manufacturing processes for batteries: winding and stacking processes. The blade battery adopts advanced high-speed stacking process, the length of the stacking pole piece can reach about 1000mm, the stacking alignment tolerance is within ±0.3mm, and the single stacking efficiency is 0.3s/pcs.

Where is BYD's largest battery production base?

The landscape of Bishan District, Chongqing. (Photo/Bishan District) Bishan District in Chongqing is home to BYD's first and largest Blade Battery production base, where a new battery is produced every six seconds. As highlighted in a press conference on November 8, Blade Battery contributes 70% of the city's total power battery output.

What is a blade battery?

They serve asf the bedrock for efficient and stable production, in turn forming the backbone of the Blade Battery’s quality. The Blade Battery refers to a single-cell battery with a length of 96 cm, a width of 9 cm and a height of 1.35 cm, which can be placed in an array and inserted into a battery pack like a blade.

Update Information

- Blade battery cabinet direct heating and cooling technology

- Fully automatic lithium battery station cabinet production line

- Mongolia lithium battery station cabinet production

- Energy storage cabinet battery 5MWH liquid cooling production

- Battery production energy storage cabinet

- Telecom battery cabinet production

- Battery cabinet production line base station

- Vientiane high temperature resistant battery cabinet production

- Where is the original production place of the energy storage cabinet battery

- How to choose battery cabinet production

- Battery cabinet production in Podgorica with quality assurance

- Battery cabinet production in Sri Lanka

- Battery cabinet cold plate production integrated system

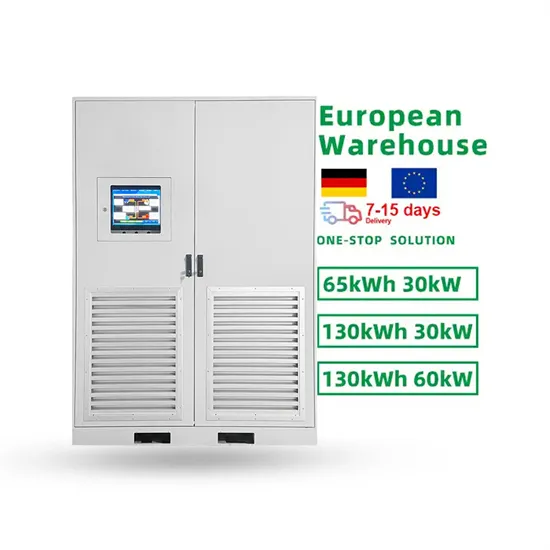

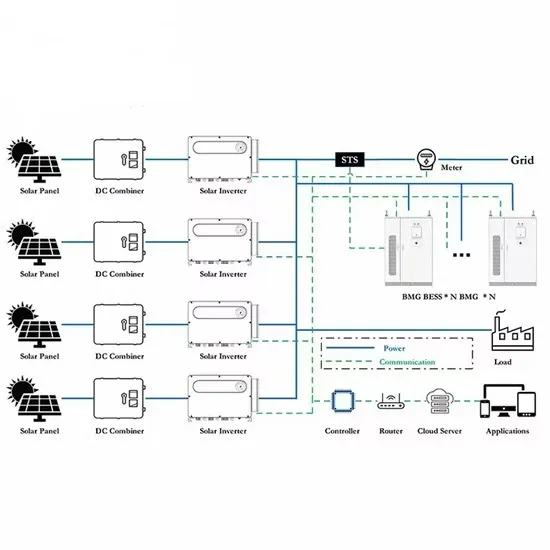

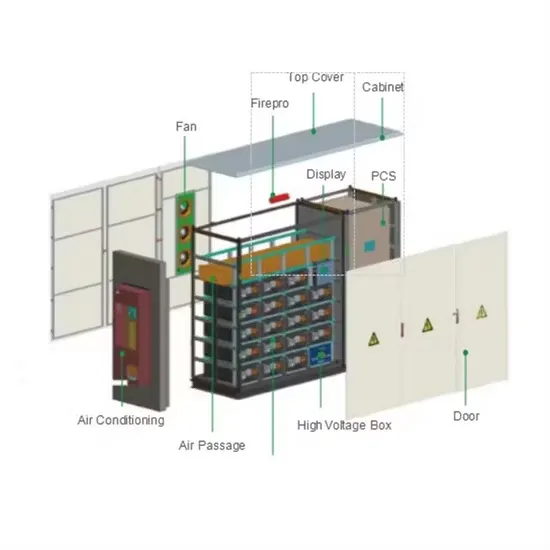

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.