Research progress on power battery cooling technology for

Feb 1, 2020 · In the charging and discharging process of new energy vehicles, how to maintain power battery within optimum operating temperature range, reduce the peak temperature and

Battery Cabinet Cooling Requirements | We Group E-Site

Battery cabinet cooling requirements have become the linchpin of modern energy infrastructure. A single temperature spike beyond 45°C can trigger irreversible capacity loss – but is forced air

Liquid Cooling Battery Cabinet: Modern BESS Technology

Advancements in Battery Cabinet Cooling Technology Historically, battery thermal management relied on simpler methods like air cooling, where fans circulate ambient air to dissipate heat.

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

The Importance of Advanced Thermal Management Effective temperature control is paramount for the health of any battery energy storage system (BESS). Traditional air cooling methods, while

Thermal Management Design for Prefabricated Cabined Energy

Jul 31, 2022 · With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissipation and inability

A novel thermal management system for lithium-ion battery

Sep 1, 2023 · The safety, lifespan and performance of lithium-ion battery are closely related to its working temperature. A large amount of heat will be generated inside the battery during

Optimization and Energy Consumption Analysis of the Cooling

Dec 16, 2023 · Currently, four cooling methods are available for batteries: air cooling, heat sink liquid cooling, secondary loop liquid cooling, and refrigerant two-phase cooling. In this article,

Energy, economic and environmental analysis of a combined cooling

Sep 10, 2024 · Huge energy consumption of data centers has become a concern with the demand for greater computing power. Indirect liquid cooling is currently the main cooling method for the

Thermal Management Solutions for Battery Energy Storage Systems | New

Jul 6, 2023 · The widespread adoption of battery energy storage systems (BESS) serves as an enabling technology for the radical transformation of how the world generates and consumes

Energy Storage Battery Cabinet Design Method

Energy Storage Battery Cabinet Design Method Polarium BESS consists of our Battery Cabinets with a capacity of 140 kWh, Inverter Cabinets with one 75 kVA bi-directional inverter per

Field investigation on the performance of a novel hybrid cooling

Traditional liquid cooling systems of containerized battery energy storage power stations cannot effectively utilize natural cold sources and have poor temperature uniformity. To address these

Outdoor liquid cooled battery cabinet

Jun 25, 2024 · Preferred battery, first-line brand 280/314Ah LFP battery, the longest cycle life of 12000Cycle Variable frequency liquid cooling, new intelligent temperature control

Experimental and numerical investigation of a composite

Mar 1, 2025 · Traditional air-cooled thermal management solutions cannot meet the requirements of heat dissipation and temperature uniformity of the commercial large-capacity energy storage

Liquid Cooling Battery Cabinet: Innovation in Energy Systems

In the rapidly evolving landscape of energy storage, the efficiency and longevity of battery systems are paramount. A critical component ensuring optimal performance, especially in high

(PDF) State-of-the-art Power Battery Cooling Technologies for New

Apr 14, 2023 · The research on power battery cooling technology of new energy vehicles is conducive to promoting the development of new energy vehicle industry.

Analysis of Influencing Factors of Battery Cabinet Heat

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Thermal runaway behaviour and heat generation

Mar 1, 2024 · Currently, the application of lithium-ion batteries in electric vehicles has become common in recent years. Considering the adjustment and transformation of the future energy

Industry Developments: Cabinet Cooling Solutions

Sep 24, 2018 · The Blade air conditioners series, also from IceQube, is specially-designed for door mount applications on electrical enclosure cabinets. They

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Apr 29, 2025 · There are several cooling methods commonly used for cabinet cooling in energy storage systems. Each method has its own advantages and disadvantages, and the choice of

Study on performance effects for battery energy storage

Feb 1, 2025 · The purpose of this study is to develop appropriate battery thermal management system to keep the battery at the optimal temperature, which is very important for electrical

Cooling Fans or Liquid Cooling for energy storage cabinets?

Apr 28, 2025 · With booming investment in new energy storage and industrial/commercial energy storage markets everywhere, one of the most frequent questions I get from customers

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Liquid Cooling Battery Cabinet: Efficient Solution

Advanced Battery Cabinet Cooling Technology is setting a new standard for the industry, enabling higher performance, greater safety, and improved economic returns on energy storage

Cabinet Air Conditioner for Battery Energy

Aug 19, 2025 · Applications Our Battery Energy Storage System (BESS) Liquid & Air Cooling Solutions are designed for a wide range of applications, ensuring

6 FAQs about [New Energy Battery Cabinet Cooling Method]

Is liquid cooling a viable solution for battery energy storage systems?

With increasing regulatory requirements and the push for sustainability, liquid cooling is rapidly becoming the preferred solution for battery energy storage systems. Companies investing in liquid-cooled air conditioners and advanced energy storage cooling systems will benefit from enhanced efficiency, improved safety, and long-term cost savings.

How does liquid cooling work in battery energy storage systems?

The above diagram illustrates how liquid cooling works in battery energy storage systems. The coolant circulates through cold plates attached to battery modules, absorbing heat and transferring it to an external refrigerant cycle, ensuring maximum efficiency.

Why is liquid cooling important for energy storage systems?

With sustainability and high-performance applications becoming a priority, liquid cooling is emerging as the most effective technology for energy storage systems. Effective cooling is crucial in battery storage systems to prevent overheating, ensure longer battery lifespan, and optimize efficiency.

Can a battery energy storage system fit a closed-loop air conditioner?

A leading manufacturer of battery energy storage systems contacted Kooltronic for a thermal management solution to fit its rechargeable power system. Working collaboratively with the manufacturer, Kooltronic engineers modified a closed-loop air conditioner to fit the enclosure, cool the battery compartment, and maximize system reliability.

What is a battery energy storage system?

Battery energy storage systems (BESS) ensure a steady supply of lower-cost power for commercial and residential needs, decrease our collective dependency on fossil fuels, and reduce carbon emissions for a cleaner environment.

Can battery energy storage systems be used outside?

However, the electrical enclosures that contain battery energy storage systems are often located outdoors and exposed to extreme temperatures, severe weather, humidity, dirt, and dust. Like most heat-sensitive electrical equipment, operation within hot and cold temperatures can, over time, reduce power output and longevity.

Update Information

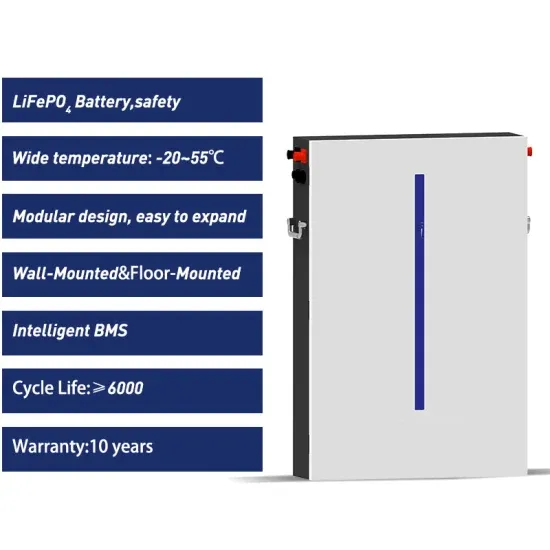

- New Energy Natural Cooling Battery Cabinet

- New Energy Battery Cabinet Cooling

- New energy battery cabinet fan cooling principle

- Georgetown New Energy Telecommunication Power Supply Battery Cabinet Factory

- New energy battery cabinet cell voltage is low

- New energy battery cabinet testing fee

- Price of new energy battery cabinet

- There are several types of batteries in the new energy battery cabinet

- Basseterre new energy battery cabinet replacement

- Nassau New Energy Battery Cabinet

- New Energy Battery Cabinet Base Station Power Structure

- How much negative charge does the new energy battery cabinet have

- Lithium battery site cabinet energy storage liquid cooling

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.