The principle of automatic door opening of energy

At the core of battery energy storage space lies the basic principle of converting electrical power right into chemical energy and, after that, back to electric power when needed.

Principle of new energy storage cabinet

The development of clean energy and the progress of energy storage technology, new lithium battery energy storage cabinet as an important energy storage device, its structural design

Cooling principle of new energy battery motor

Effective battery cooling measures are employed to efficiently dissipate excess heat,thereby safeguarding both the charging rate and the battery from potential overheating issues.

Energy Storage Fan Technical Guidance: How to Choose the Right Cooling

Dec 25, 2019 · Whether you''re an engineer designing battery cabinets or a maintenance pro keeping grid-scale storage running smoothly, this guide serves up the essential recipe for fan

Principle of heat and cold management of new energy batteries

This paper briefly introduces the heat generation mechanism and models, and emphatically summarizes the main principle, research focuses, and development trends of cooling

Battery cabinet cooling system working principle

sign key points of power battery cooling system. The excellent power battery cooling system can effectively control battery the temperature, improve the safety, performance and service life of

Principle of cooling device for new energy battery cabinet

The "Energy Storage Medium" corresponds to any energy storage technology, including the energy conversion subsystem. For instance, a Battery Energy Storage Medium, as illustrated

New energy battery cabinet fan cooling principle

In this paper, the working principle, advantages and disadvantages, the latest optimization schemes and future development trend of power battery cooling technology are larger the

Immersion cooling technology development status of

With the continuous development of data centers and information technology equipment, data center energy consumption continues to increase, China''s data center energy consumption

working principle of energy storage battery air cooling system

A systematic review of thermal management techniques for electric vehicle batteries A systematic examination of experimental, simulation, and modeling studies in this domain,

New Energy Vehicle Technology: Principle of Power Battery Cooling

Working Principle and design key points of power battery cooling system. The excellent power battery cooling system can effectively control battery the temperature, improve the safety,

Working principle of heat dissipation of new energy

The principle of air cooling heat dissipation is to generate cold and hot air flow through ambient air, self-provided equipment, or external auxiliary equipment, such as fans, to achieve

What are the air cooling technologies for new energy

As liquid-based cooling for EV batteries becomes the technology of choice, Peter Donaldson explains the system options now available. A fluid approach. Although there are other options

Battery Cabinet Convection Cooling and CoolCab Fan

Feb 7, 2020 · eratures of batteries while enclosed in battery cabinets. Small strategic changes in airflow have a big effect on a cabinet''s abi ity to transport heat up and out the rear of the

Battery cabinet cooling system working principle

The efficient control and regulation of cooling mechanisms and temperature are of utmost importance to uphold battery performance, prolong battery lifespan, and guarantee the safe

working principle of cooling fan for energy storage equipment

What is the working principle of the cooling fan?-Shenzhen Ying Tian Mechatronics Equipment The cooling fan is a new type of electromechanical integration fan, which uses the

(PDF) State-of-the-art Power Battery Cooling Technologies for New

Apr 14, 2023 · In this paper, the working principle, advantages and disadvantages, the latest optimization schemes and future development trend of power battery cooling technology are

A review of power battery cooling technologies

May 1, 2025 · Lithium-ion batteries are a promising solution for achieving carbon neutrality in transportation due to their high energy density and low self-discharge rates. However, an

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Apr 29, 2025 · In the realm of energy storage systems, cabinet cooling stands as a crucial element that significantly impacts the performance, reliability, and lifespan of the entire setup.

New energy battery refrigeration principle

In practical applications, lithium-ion batteries have the advantages of high energy density [16], high power factor [17, 18], long cycle life [19], low self-discharge rate [20], good stability [21],

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

How Battery Cabinet Cooling Technology Works The core principle behind Battery Cabinet Cooling Technology is its superior heat transfer capability. In a typical setup, a dielectric

Experimental investigation of thermoelectric cooling for a new battery

Jun 1, 2021 · In this paper, a new design of a battery pack is proposed which includes an acrylic battery container, copper battery holders, liquid cooling medium, and battery cells. This battery

Structural principle of new energy battery cabinet

What are structural batteries? This type of batteries is commonly referred to as "structural batteries". Two general methods have been explored to develop structural batteries: (1)

Analysis of 3 technical routes of power battery

Apr 3, 2020 · The cooling performance of the power battery directly affects the efficiency of the battery, and also affects the battery life and safety. Because

6 FAQs about [New energy battery cabinet fan cooling principle]

Can a battery container fan improve air ventilation?

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized system for the development of a healthy air ventilation by changing the working direction of the battery container fan to solve the above problems.

Does fan direction control improve cooling performance of battery packs?

Cooling performance of battery packs under different design options. In summary, the thermal management strategy based on fan direction control proposed in this paper has significant advantages when thermal management of battery pack groups in energy storage battery systems is performed.

How to improve the cooling system?

Based on the results and the problems of the initial cooling system, four improvement strategies are proposed. First, it is defined that the air flow is drawn from the battery pack into the container as the suction state, and vice versa as the blown state.

What is the corresponding heat generation power of a battery?

The inlet boundary is a velocity inlet of 2.6 m/s and the outlet boundary is a pressure outlet of 0 Pa. In addition, the temperature of the supply airflow is 293.15 K. The battery has a discharge rate of 0.5C and an internal resistance of 0.3mΩ. Using Bernardi's theory, the corresponding heat generation power of the battery is 1132.91 W/m 3.

How does a cooling strategy improve temperature inhomogeneity?

This new cooling strategy improved the temperature inhomogeneity by reducing the temperature uniformity between cells by 3.2 °C and by reducing the consumed cooling flow by 38 %. Shi et al. investigated the effect of setting the air inlet on the side wall of the battery pack to the internal temperature field.

How to reduce the temperature of a battery pack?

In optimized solution 2, the temperature of the corresponding battery packs is reduced by changing the state of the fan in battery packs 4 and 11. In optimized solution 3, the temperature of the corresponding battery pack has been significantly reduced by further changing the status of the fan in battery packs 1 and 8.

Update Information

- New Energy Battery Cabinet Cooling

- New Energy Battery Cabinet Cooling Method

- New Energy New Energy Battery Cabinet Structure

- Belgrade Customized New Energy Battery Cabinet

- Conakry new energy battery cabinet size

- How big is the single battery in the new energy battery cabinet

- How to install the new energy battery cabinet for conversion equipment

- What is the brand of new energy battery cabinet

- How long does it take to charge a new energy battery cabinet

- New energy battery storage cabinet processing manufacturer

- New energy battery cabinet self-service charging

- Xia New Energy Lithium Battery Station Cabinet

- Polyurethane in new energy battery cabinet

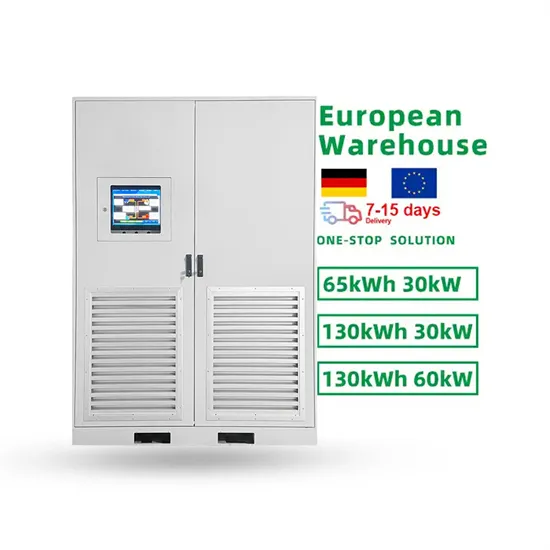

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.