Welding techniques for battery cells and resulting electrical

Jun 1, 2015 · The three welding techniques were applied to cylindrical lithium-ion cells of 26650 size. As external conductor a CuZn37 sheet of 0.2 mm thickness was welded at the negative

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The ability to correctly predict the behavior of lithium ion batteries is critical for safety, performance, cost and lifetime. Particularly important for this purpose is the prediction

车用圆柱锂电池及模组的机械完整性

In order to provide a highly accessible method to explore the mechanical integrity of automotive cylindrical lithium-ion batteries (LIBs) and battery modules, a series of multidirectional loading

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Research on cooling and fixing of lithium-ion battery cooling

As the inlet flow rate of the integrated liquid-cooled plate increased from 30 ml/min to 60 ml/min, the maximum and minimum temperatures of the battery pack decreased considerably,

Dynamic mechanical integrity of cylindrical lithium-ion battery

Jul 1, 2015 · Further, by considering the strain rate and inertia effect of the battery structural and material, the dynamic mechanical behavior of lithium-ion battery is investigated. Different

Tab Design and Failures in Cylindrical Li-ion Batteries

Feb 15, 2019 · Lithium-ion (Li-ion) batteries play a vital role in today''s portable and rechargeable products, and the cylindrical format is used in applications ranging from e-cigarettes to electric

Investigation of novel type of cylindrical lithium-ion battery

Sep 30, 2024 · The in-depth research on the heat exchanger for lithium-ion batteries is of significant importance due to its crucial role in ensuring the safe operat

Cylindrical battery cell fixing bracket for lithium battery

The utility model relates to a cylindrical battery cell fixing bracket for a lithium battery, wherein the bracket is provided with battery cell fixing grooves; the battery cell fixing grooves are regularly

Development and Analysis of a New Cylindrical Lithium-Ion Battery

Jul 30, 2022 · This paper aims to design and optimize a new indirect liquid cooling system for cylindrical lithium-ion batteries. Various design schemes for different cooling channel

HPQ Silicon Launches ENDURA+ 18650 and 21700 Li-Ion Cells

Aug 15, 2025 · HPQ Silicon has begun producing ENDURA+ cylindrical lithium-ion cells using Novacium''s GEN3 silicon anodes, in 4,000 mAh 18650 and 6,000 mAh 21700 formats.

Simulation study of a cylindrical battery module

Apr 1, 2022 · Considering that the battery module is a part of the electric vehicle structure, the long cylindrical lithium battery module structure is proposed in order to reduce the weight of

Dynamic failure mechanisms of cylindrical lithium-ion batteries

Aug 1, 2025 · Failure mechanisms of batteries are revealed upon multi-physical responses and cross-scale morphologies. Component-level failure behaviors are presented employing the

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Cylindrical Lithium-ion Batteries have been used in many electronic devices. The electrochemical cell of the batteries consists of a layer of positive electrode, a layer of negative

Dynamic crushing behaviors and failure of cylindrical lithium

Dec 1, 2023 · The mechanical property and failure prediction play a significant role in engineering applications of lithium-ion batteries (LIBs), but with great difficulties due to their complicated

Cylindrical lithium ion battery – types,

Aug 4, 2023 · This article provides an overall introduction of cylindrical lithium ion battery, about its different types and different sizes, also the pros and cons.

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · Effective BTMS is essential to keep LIBs in their optimal operating temperature range. Efficient thermal management methods are required because research has shown that

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Performance enhancement for a novel cylindrical system Li‐ion battery

Nov 4, 2024 · This research looks at the impact of dielectric fluids and fluid speeds on cell temperature control in innovative cylindrical lithium-ion batteries during high-rate discharges (C

6 FAQs about [Cylindrical lithium battery fixing]

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

Update Information

- Lithium battery assembly cylindrical

- Lithium battery cylindrical technology

- Lithium battery cylindrical to nickel

- Professional cylindrical lithium battery of different models

- Cylindrical lithium battery assembly parts wholesale

- The smallest cylindrical rechargeable lithium battery

- Marshall Islands cylindrical lithium battery 7260

- Lithuania s largest cylindrical lithium battery

- Paramaribo lithium battery cylindrical cell

- Mongolian cylindrical lithium battery is a battery

- Azerbaijan cylindrical lithium battery model

- Djibouti cylindrical lithium battery module manufacturer

- Large cylindrical lithium battery model

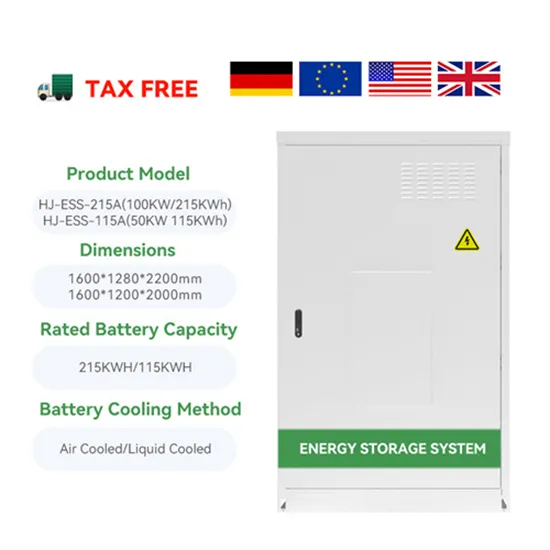

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

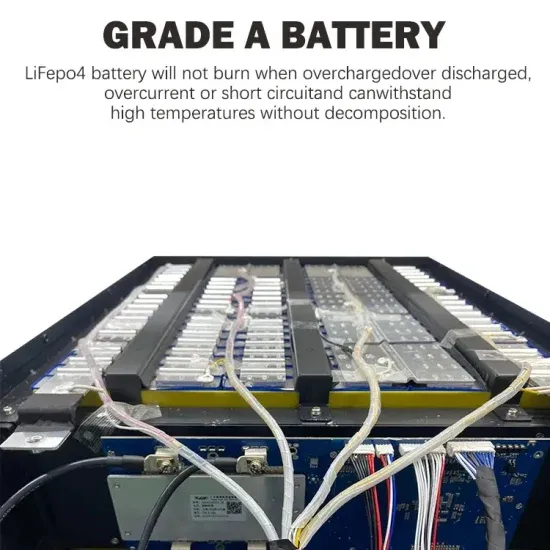

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.