A novel active lithium-ion cell balancing method based on

May 6, 2025 · This ensures the better performance of the proposed cell balancing as compared to other (Voltage/SoC-based) balancing in maximizing the battery pack capacity and minimizing

(PDF) Study on the Charging and Discharging

Sep 13, 2018 · This solution is based on treating and filtering a time series in real-time software, using the battery pack characteristic discharge curve and time

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · For a single cell, Table 6 shows a voltage range from 2.75 to 4.2 V, a charging rate up to 2600mA (1C) and discharging rate up to 5200mA (2C). For multiple-cell packs, the

Unlocking the Power: Distinguishing Battery

Dec 17, 2024 · - Voltage: Delivers a single unit of voltage (usually 3.7V for lithium-ion) Fun Fact: The AA battery you use in your remote control is actually just

Active balancing method for series battery pack based

Jan 11, 2021 · To improve the consistency of the series battery pack, a novel balancing method based on the flyback converter is proposed in this study. The flyback converter with a simple

Non-Dissipative Battery Cell Balancing Using Half-Bridge

Sep 19, 2017 · A cell balancing system serves to extend battery run time as well as remaining useful life for a system utilizing multiple such cells in series. In order to maximize the use of a

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Bidirectional Active Equalization Control of

Sep 28, 2024 · Aiming at the energy inconsistency of each battery during the use of lithium-ion batteries (LIBs), a bidirectional active equalization topology of

A review of equalization strategies for series battery packs:

Dec 1, 2019 · Inconsistency in the internal parameters and external environments of lithium-ion cells after they are connected as a battery pack may greatly limit the pack''s capacity, power

Multi-Objective Predictive Balancing Control of Battery

Sep 22, 2023 · Abstract: Various balancing topology and control methods have been proposed for the inconsistency problem of battery packs. However, these strategies only focus on a single

Design of optimized single-switch capacitor cell balancing

The research explores the implementation of shuttling single-switched capacitor-based active cell balancing in BMS for EVs, aiming to address critical challenges such as balancing speed,

Design and implementation of an inductor based cell

Nov 20, 2024 · Cells in a battery pack are imbalanced during charging and discharging due to the design parameters of cells in a battery pack which results in battery degradation and an

A comprehensive review of battery modeling and state

Oct 1, 2020 · The main technical difficulties restricting the development of battery management technology can be concluded in the following three aspects: (1) the lithium battery system is

Test Battery Cells, Modules and Packs with EA-BT 20000

Jun 4, 2024 · The BT 20000 Battery Tester combines the power to test high-power battery packs with kW capacity and the accuracy to test individual cells and modules in a single, eficient

Optimal fast charging strategy for series-parallel configured

Jan 1, 2025 · Despite the extensive research dedicated to optimizing the charging process for single cells, control strategies for packs remain unexplored. This paper focuses on the battery

(PDF) Charging and Discharging Control of Li

Nov 30, 2018 · Nevertheless, li-ion battery needs protective mechanism to control overcharged or undercharged of the cell that can reduce the life expectancy

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

LM3655 Charge Control and Protection IC for embedded

Dec 9, 2009 · The LM3655 provides complete charge control, discharge control and battery safety of a single Lithium-Ion cell. It supports battery charging by using a variety of power supply

Battery management systems (BMS) | Infineon Technologies

Infineon''s battery management solutions and reference designs for automotive or industrial and consumer applications help you lay out your battery management system to perfectly fit your

Parallel battery pack charging strategy under various

May 20, 2022 · In this study, a battery model for a single cell is established by coupling a single particle model with electrolyte, degradation model, and thermal model. Besides, considering

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · Bypassing the low cell during end of discharge phase can increase battery useful discharge time, but to be effective it requires high-rate capable by-pass capability which is

Active Cell Balancing in Battery Packs

Nov 23, 2016 · There are two main methods for battery cell charge balancing: passive and active balancing. The natural method of passive balancing a string of cells in series can be used only

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · This work also investigates the effects of forced air-cooling systems focusing on battery pack hot spots and temperature distributions. The results show a good fit between

Investigation of the electrical and thermal

Sep 1, 2024 · The results showed that when high-rate discharge occurs, the upper part of the battery is the high-temperature zone from the beginning of discharge. With the increase of

Capacity estimation for series-connected battery pack based

Aug 1, 2024 · Subsequently, by optimizing the transformation coefficients, we achieve capacity estimation for each cell within the battery pack utilizing only a partial charging voltage profile at

ITS5300 Battery Charge & Discharge Test System

Mar 20, 2019 · Real-time temperature and other parameters of single cell can achieve system'' overvoltage, under voltage, overcurrent, overheating protection and the battery pack

Battery Pack Discharge Control with Thermal Analysis

Nov 6, 2020 · Introduction Thermal management is important in battery modeling. This example computes the temperature distribution in a battery pack during a 4C discharge. To ensure a

A fast active balancing strategy based on model predictive control

Sep 15, 2023 · The consistency of lithium-ion battery packs is extremely important to prolong battery life, maximize battery capacity and ensure safety operation in electric vehicles. In this

Update Information

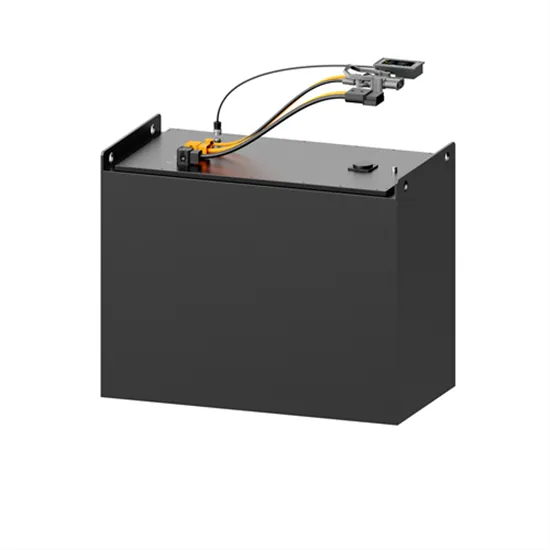

- Large single cell battery module pack

- Lithium battery cell large single cylinder

- Which battery cell is better for Roman lithium battery pack

- Battery pack and cell

- Assemble 60V battery pack using single lithium battery

- Tanzania electric sanitation vehicle lithium battery pack

- Pack battery quality inspection

- Togo Lithium Battery Pack Flat EK

- Spanish 72v lithium battery pack

- Lithium battery pack heat dissipation

- Mechanical lithium battery pack

- Kyrgyzstan energy storage lithium battery manufacturer system battery pack

- Ethiopian flashlight lithium battery pack

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

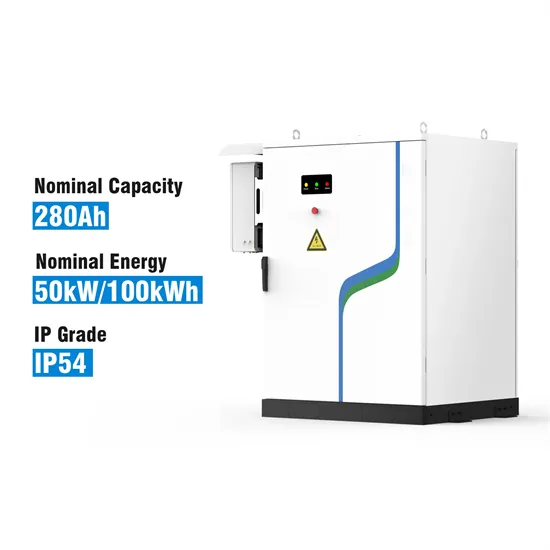

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.