What is Battery Cell, Battery Module, and Battery

Jul 15, 2024 · It is important to understand the difference between a battery cell, battery module and battery pack if you work in industries such as electric

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

Comprehensive understanding of the effects of imbalanced cell

Mar 1, 2025 · In this study, a comprehensive understanding on the battery module with an imbalanced cell is assessed in terms of its electrical, thermal, and electrochemical effects. By

The Fundamentals of Battery Module and Pack Test

Oct 17, 2023 · The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy

A systematic comparison of the packing density of battery cell-to-pack

Mar 1, 2022 · For this purpose, battery concepts are created under cell-to-pack aspects based on a conventional concept and investigated with regard to the geometric layout and the

Introduction to Electric Vehicle Battery Modules and Packs

4 days ago · 12V battery packs for accessories 12V battery packs provide power to low energy accessories and applications in a vehicle, such as headlights and radio. How EV battery packs

Enabling New EV Battery Chemistries Through Battery Pack

Jan 7, 2025 · This article discusses the changes in battery pack design that impact which cell chemistries can be used in a commercially viable way. An overview is given for future adoption

[Battery101] Cell, Module, and Pack of Batteries

Aug 30, 2024 · BMW iX xDrive50 model is equipped with 500 prismatic cells, but instead of having 500 cells individually, we take 40 or 50 cells and make them

What Are the Differences Between Battery Cell, Module, and Pack?

Apr 11, 2025 · What Are the Differences Between Battery Cell, Module, and Pack? A battery cell is the basic energy unit, a module groups cells for stability, and a pack combines modules with

A cell level design and analysis of lithium-ion battery packs

Oct 31, 2024 · The world is gradually adopting electric vehicles (EVs) instead of internal combustion (IC) engine vehicles that raise the scope of battery design, battery pack

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · In modern energy storage systems, batteries are structured into three key components: cells, modules, and packs. Each level of this structure plays a crucial role in

Difference between Battery Module And Battery

Oct 12, 2022 · In general, a battery module is a collection of individual batteries that are connected together to form a larger unit, while a battery pack is a

How to Distinguish Battery Cells, Battery Modules, and Battery Packs?

Battery Cells Battery Modules Battery Packs Each contains Battery Cells: Consist of the electrodes (anode and cathode), electrolyte, separator, and casing. These individual

Battery pack diagnostics for electric vehicles: Transfer of

Dec 1, 2024 · Aging of lithium-ion battery cells reduces a battery electric vehicle''s achievable range, power capabilities and resale value. Therefore, suitable characterization methods for

Battery Cell vs Battery Module vs Battery Pack

Mar 15, 2023 · Battery Module: Explanation and Function Unveil the significance of battery modules with these key insights: Bridge Between Cells and Packs:

Cell to Pack: Key Design Considerations for CTP

Feb 1, 2025 · What is a CTP battery? A CTP battery stands for Cell-to-Pack ⇱. It''s a way of putting together battery packs that makes them lighter and more

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Battery Cell Module Pack: Everything You Need

Sep 27, 2024 · While the terms "battery cell," "battery module," and "battery pack" are often used interchangeably, the battery cell module pack refers to different

Battery cell, Battery Module or Pack. What''s the

Jun 20, 2023 · Battery modules and packs are not the same; they represent different stages in battery applications and have distinct differences What are

3 FAQs about [Battery pack and cell]

What are battery cells & modules & packs?

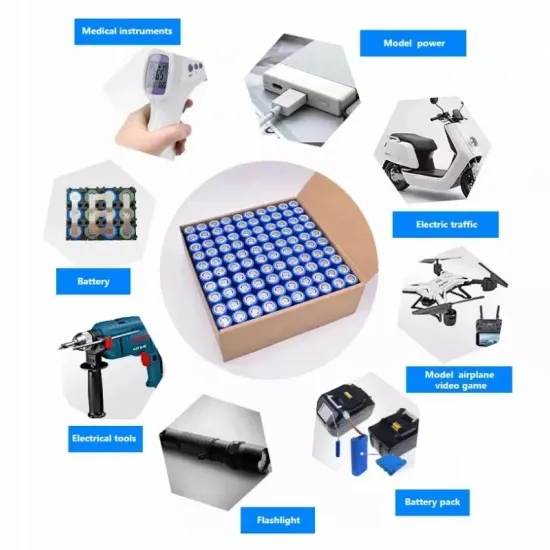

Battery cells, modules, and packs are different stages in battery applications. In the battery pack, to safely and effectively manage hundreds of single battery cells, the cells are not randomly placed in the power battery shell but orderly according to modules and packages. The smallest unit is the battery cell. A group of cells can form a module.

How a battery pack works?

In the battery pack, to safely and effectively manage hundreds of single battery cells, the cells are not randomly placed in the power battery shell but orderly according to modules and packages. The smallest unit is the battery cell. A group of cells can form a module. Several modules can be combined into a package.

What is cell to pack?

This method is said to be cell to pack, when a cell has excess charge switching allows the cells to provide a discharge current into its transformer where the energy is stored within the magnetic field. When the switch is turned off the stored energy is then redistributed into all other connected transformers, and therefore, cells.

Update Information

- Large single cell battery module pack

- Battery pack and cell

- Qatar good lithium battery pack factory price

- Ljubljana standard lithium battery pack ex-factory price

- Caracas home battery pack

- H lithium battery pack

- Low speed lithium battery pack wholesale

- Belarus Gomel ups power supply lithium battery pack

- Plug-in device for lithium battery pack

- Lithium battery pack heat dissipation

- 18505 Lithium Battery Pack Specifications

- Pack battery factory construction feasibility

- New Zealand lithium battery pack

Solar Storage Container Market Growth

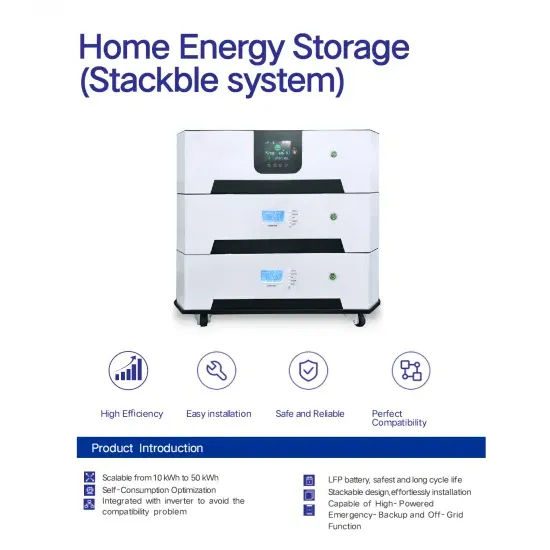

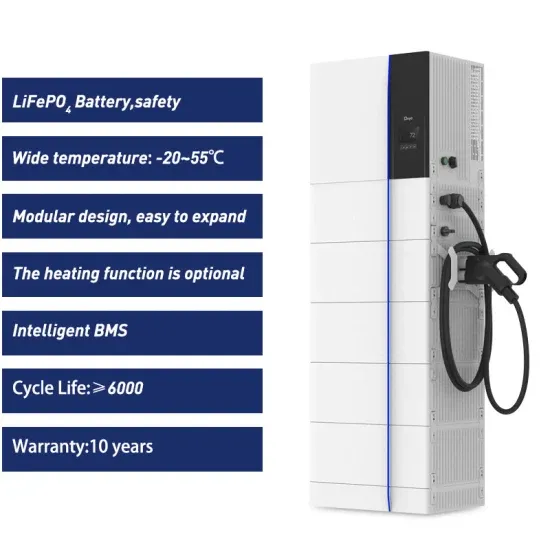

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.