Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · This paper is a comprehensive numerical investigation of the optimization of thermal management systems of lithium-ion batteries (LIBs) through the synergistic integration

Analysis of Cell Balancing Techniques for Li-ion Batteries

Oct 19, 2024 · Effective cell balancing is crucial for optimizing the performance, lifespan, and safety of lithium-ion batteries in electric vehicles (EVs). This study explores various cell

Thermal Investigation of Cylindrical Lithium-ion Batteries for

Dec 8, 2022 · Thermal investigation of cylindrical lithium-ion batteries of different chemistry and shape factors (18650 NMC and 21700 NCA) is conducted for different charging/discharging

Optimization of fast-charging strategy for LISHEN 4695 cylindrical

Feb 15, 2025 · Abstract Developing fast-charging technology for lithium-ion batteries with high energy density remains a significant and unresolved challenge. Fortunately, the advent of the

Novel hybrid thermal management system for cylindrical lithium

Aug 15, 2025 · The curved surface of cylindrical batteries makes full contact with the cold plate difficult [27], potentially leading to large temperature differences under abuse conditions.

Aging behavior and mechanisms of lithium-ion battery

Oct 15, 2023 · Local lithium plating significantly affects battery safety and cycle life. This study investigated the aging of lithium-ion batteries (LIBs) cycled at

Safety and reliability analysis of lithium-ion batteries with

Apr 1, 2025 · Battery form factors, whether pouch, cylindrical, or prismatic cells affect the integration and packaging of batteries within the vehicle''s layout. Different form factors have

An energy balance evaluation in lithium-ion battery module

Jan 1, 2021 · This paper deals with the analysis of the energy balance in a battery module made of 18650 cylindrical lithium-ion cells based on a simple electrothermal model extended with

Elucidating effects of form factors on thermal and aging

Apr 1, 2025 · Lithium-ion batteries have witnessed tremendous growth since their commercial introduction in 1991 and have become a popular battery technology for a variety of

Formal Approaches to Design of Active Cell Balancing

Feb 10, 2021 · In contrast to the dissipative approach of passive cell balancing, active balancing architectures e ciently transfer charge between battery cells and can therefore also equalize a

A Tutorial into Practical Capacity and Mass Balancing of

The development of highly energy efficient and reliable electro-chemical energy storage systems plays a key role in the field of alter-native energy sources and electro-mobility.1–4 Lithium ion

Off-line method to determine the electrode balancing of Li-ion batteries

May 1, 2021 · In this paper, we propose a non-invasive method to determine the electrode balancing of the lithium-ion batteries, which is the determination of (i) individual electrodes

Performance study on a novel hybrid thermal management

Jul 15, 2025 · High energy density cylindrical lithium-ion battery packs face severe thermal challenges under high intensity discharge conditions, which significantly reduce the

Performance Analysis of Optimized Active Cell Balancing

Mar 10, 2025 · The increasing need for reliable and efficient energy storage solutions has brought a strong focus on enhancing the performance of lithium-ion batteries (LIBs), especially for high

BAK''s big cylindrical battery will support mid-to-high-end EV

Feb 16, 2022 · As the firstly lithium battery company in China to release the 4680 full-tab big cylindrical, BAK''s progress in the research and development of full-tab big cylindrical batteries

Passive Balancing vs Active Balancing in Lithium Batteries

Jun 19, 2025 · Passive balancing is one of the most straightforward battery balancing methods used in lithium battery packs. It operates by dissipating excess energy from overcharged cells

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · Different algorithms of cell balancing are often discussed when multiple serial cells are used in a battery pack for particular device. The means used to perform cell balancing

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · This study presented an electrochemical-thermal model for cylindrical lithium-ion batteries, integrating a detailed multi-layer thermal framework with electrochemical dynamics.

Liquid-immersed thermal management to cylindrical lithium-ion batteries

Apr 30, 2024 · Immersed thermal management shows distinct advantages while cooling the lithium-ion battery modules. This work conducts numerical-experimental studies to analyze the

(PDF) Formal approaches to design of active cell

Nov 7, 2016 · Large battery packs composed of Lithium-Ion cells are continuously gaining in importance due to their applications in Electric Vehicles (EVs) and

Investigation on thermal management of cylindrical lithium

Aiming to tackle the issues of excessive module temperature and inadequate thermal balance of vehicle power batteries under high discharge rates, a novel interwound cooling belt structure

Cycle life studies of lithium-ion power batteries for electric

Jul 15, 2024 · Cycle life is regarded as one of the important technical indicators of a lithium-ion battery, and it is influenced by a variety of factors. The study of the service life of lithium-ion

Impact of Electrode and Cell Design on Fast

Sep 16, 2020 · Cylindrical formats for high energy lithium-ion batteries shifted from 18650 to 21700 types offering higher volumetric energy density and lower

How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Active Li-ion Battery Charge Balancing System Based on

Nov 4, 2020 · Abstract— The paper deals with the design of an active battery charge balancing system for Li-ion batteries. The Li-ion batteries are sensitive to series connection and thus

Active cell balancing of Li-ion Battery pack

Jun 4, 2025 · Hi, I''m working on a project to design an active cell balancing model for Li-ion battery pack using a battery pack. I''m having trouble starting this project. Can somebody

Thermal management of cylindrical lithium-ion batteries

Jul 15, 2025 · Effective BTMS is essential to keep LIBs in their optimal operating temperature range. Efficient thermal management methods are required because research has shown that

A novel active cell balancing topology for serially connected

Aug 10, 2024 · In a Battery Management System (BMS), cell balancing plays an essential role in mitigating inconsistencies of state of charge (SoCs) in lithium-ion (Li-ion) cells in a battery

6 FAQs about [Balancing of cylindrical lithium batteries]

Do cylindrical lithium-ion batteries have a thermal stability problem?

This work is motivated by the critical need to improve the thermal stability of cylindrical lithium-ion batteries, especially in electric vehicles and high-performance electronics, where overheating during rapid charging and high discharge rates can lead to thermal runaway and decreased lifespan.

Why is balancing a lithium ion battery important?

Journal of The Electrochemical Society, Volume 164, Number 12 Citation Johannes Kasnatscheew et al 2017 J. Electrochem. Soc. 164 A2479 DOI 10.1149/2.0961712jes In a lithium ion battery, balancing of active materials is an essential requirement with respect to safety and cycle life.

How to keep a lithium ion battery balanced?

In Li-ion batteries which have very low self-discharge and therefore accumulative unbalance per cycle is usually less than 0.1%, bypass current of internal FETs is sufficient to keep the pack continuously balanced.

Can a simple battery balancing scheme reduce individual cell voltage stress?

Individual cell voltage stress has been reduced. This study presented a simple battery balancing scheme in which each cell requires only one switch and one inductor winding. Increase the overall reliability and safety of the individual cells. 6.1.

Which battery cell balancing technique is best?

The multi cell to multi cell (MCTMC) construction provides the fastest balancing speed and the highest efficiency (Ling et al., 2015). The various battery cell balancing techniques based on criteria such as cost-effectiveness and scalability is shown in Table 10. Table 10.

Does cell balancing improve battery efficiency?

The research delved into the characteristics of active and passive cell balancing processes, providing a comprehensive analysis of different cell balancing methodologies and their effectiveness in optimizing battery efficiency.

Update Information

- How many types of cylindrical lithium batteries are there

- Cylindrical lithium batteries have direction

- Managua s first mass production of cylindrical lithium batteries

- What are the types of small cylindrical lithium batteries

- Cyprus cylindrical lithium battery sales

- Cylindrical lithium battery and cube lithium battery

- Do 5g base stations need lithium batteries

- Lead-acid batteries and lithium batteries for inverters in Bulgaria

- Energy storage lead-acid batteries and lithium iron phosphate

- Are lithium batteries in photovoltaic energy storage cabinets expensive

- Overcurrent protection of cylindrical lithium battery

- Georgia develops lithium batteries for energy storage

- The principle of lithium batteries used in communication base stations

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

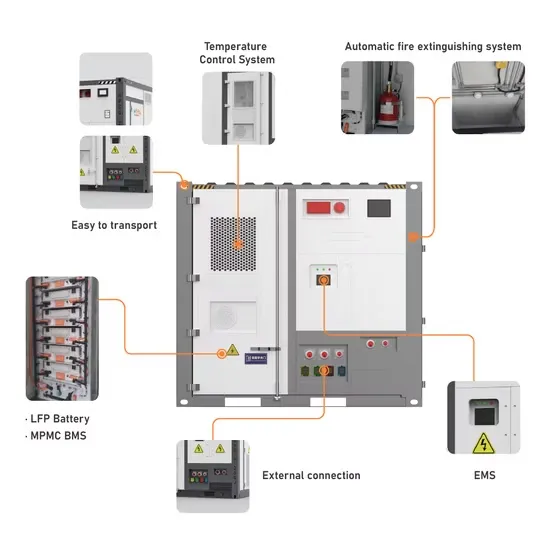

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.