Battery protection selection guide

May 24, 2025 · For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

PROTECTING RECHARGEABLE LI-ION AND LI-POLYMER

Need for Battery Protection Li-batteries are particularly sensitive to faults caused by external shorts, runaway charging conditions and abusive overcharging that can result in potentially

Modeling of the overcharge behavior of lithium-ion battery

Oct 31, 2021 · Here we extend the full-order Newman model of a lithium-ion battery cell by adding a description of the novel type of overcharge protection layer. The model was used to simulate

Simple Undervoltage and Overcurrent Protection

Mar 29, 2021 · Li-ion batteries are made with a rigid (typically cylindrical) casing while LiPo batteries come in pouches of various sizes. Due to their high

Tab Design and Failures in Cylindrical Li-ion

Feb 15, 2019 · Lithium-ion (Li-ion) batteries play a vital role in today''s portable and rechargeable products, and the cylindrical format is used in applications

Safer operating areas (SOA) of cylindrical lithium-ion battery

Oct 1, 2024 · Overcharge (often indicated by SOC) occurs when the battery''s open circuit voltage (OCV) crosses above the designed cut-off voltage, resulting de-lithiation of active lithium from

Battery protection selection guide

May 24, 2025 · Mishandling lithium batteries can lead to serious failures like thermal runaway, lithium plating, electrode decomposition, etc. Consequently, such batteries require special care

Cylindrical cells Archives — Large Battery

Mint tapasztalt cylindrical cell manufacturer, Nagy teljesítmény not only supplies individual cells but also offers custom battery pack assembly services using cylindrical formats. We work with

Microsoft Word

Apr 27, 2016 · Problem Most commercial, cylindrical lithium-ion cell design are equipped with a positive thermal coefficient (PTC) current limiting switch to provide hazard protection against

Modeling for Temperature Rise of Lithium-Ion Battery Cell in

Sep 7, 2024 · We study temperature response of battery cell to impulse overcurrent with temperature-dependent impedance. This work contributes to analyzing temperature rise

A technical perspective on cylindrical lithium

Sep 15, 2023 · 1. Cylindrical battery structure If you pay attention to lithium batteries, you will find that cylindrical 18560 batteries are the type that has

PROTECTING RECHARGEABLE LI-ION AND LI-POLYMER

overtemperature protection and overcurrent protection. ICs and MOSFETs are often used as the primary pack protection in conjunction with a fuel gauge device to track the battery cell

Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

Keeping Higher Current Lithium-ion Battery Cells Safe

LITHIUM-ION CELL SAFETY In light of such obvious hazards, cell designers should take a multi-layer protection approach. Individual cells require mechanical, electrical and thermal

6 FAQs about [Overcurrent protection of cylindrical lithium battery]

How do you safely use lithium ion or lithium polymer batteries?

To safely utilize lithium-ion or lithium polymer batteries, they must be paired with protection circuitry capable of keeping them within their specified operating range.

Why do lithium batteries need special care?

Lithium batteries are characterized by high energy and power density. Mishandling lithium batteries can lead to serious failures like thermal runaway, lithium plating, electrode decomposition, etc. Consequently, such batteries require special care in stressful conditions such as overcharge, undercharge, short circuits, overheat, etc.

What faults should a battery be protected from?

The most important faults that the batteries must be protected from are overvoltage, overcurrent, and over temperature conditions as these can place the batteries in a dangerously unstable state. The same is true for undervoltage conditions, though to a lesser extent.

Why does a load pre-charge circuit limit inrush current?

Inrush currents arise during the turn on, mainly when the battery is first connected to the load. The inrush currents can get high enough to either destroy the protection circuit or to blow of the protection fuse. A load pre-charge circuit would limit the inrush current during the turn on phase and protect both the battery and the load.

What is Infineon battery protection?

For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection circuit disconnects the battery from the load when a critical condition is observed, such as short circuit, undercharge, overcharge or overheating.

What does a battery protection circuit do?

The battery protection circuit disconnects the battery from the load when a critical condition is observed, such as short circuit, undercharge, overcharge or overheating. Additionally, the battery protection circuit manages current rushing into and out of the battery, such as during pre-charge or hotswap turn on.

Update Information

- Mobile cylindrical lithium battery

- Cylindrical lithium battery and square

- Togo custom made cylindrical lithium battery

- Lg large cylindrical lithium battery

- 60300 cylindrical lithium battery

- Greek cylindrical lithium battery

- BAK cylindrical lithium battery

- Cylindrical lithium battery sales in Costa Rica

- Belmopan Cylindrical Lithium Battery Factory

- Cylindrical lithium battery waterproof

- Uganda cylindrical lithium battery selection company

- Doha cylindrical lithium battery professional factory

- 37v rechargeable lithium battery 1200 mAh cylindrical

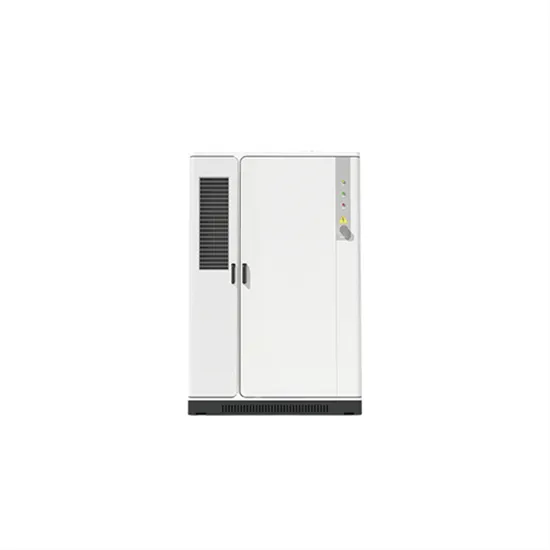

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.