Diffusion Induced Stresses in Cylindrical Lithium-Ion Batteries

Oct 17, 2012 · Abstract Analytical solutions of diffusion induced stress in a cylindrical multilayer electrode during lithiation are obtained. Design insights are provided by analyzing the diffusion

Working temperature effects on mechanical integrity of cylindrical

Jul 1, 2022 · In summary, the working temperature effects cannot be neglected in cylindric lithium-ion battery failure, and combined simulation and experimental results indicate that the short

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The ability to correctly predict the behavior of lithium ion batteries is critical for safety, performance, cost and lifetime. Particularly important

Structural analysis and experimental characterization of cylindrical

Dec 20, 2014 · In this study, we have developed and compared two homogenization methods for the jellyroll in a cylindrical lithium-ion battery cell. Homogenization was conducted in a

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Thermal parameters of cylindrical power batteries: Quasi

Oct 11, 2022 · The subsequent thermal analysis on the thermal design of cylindrical batteries is also conducted based on the measured thermal parameters, which facilitate appropriate

A universal anisotropic model for a lithium‐ion cylindrical cell

Mar 13, 2022 · As a typical form factor for Li-ion battery cells, 18,650 cylindrical batteries have geometry and electrical capabilities that make them one of the most common cells used for

Power in Cylinders: The Significance of Cylindrical Battery

Feb 21, 2025 · Cylindrical battery cells are crucial components in modern energy storage solutions, offering a range of benefits that enhance performance and efficiency.

Impact modeling of cylindrical lithium-ion battery cells: a

Oct 1, 2016 · The main goal of this study was to develop a reliable finite element model that predicts the behavior of cylindrical lithium ion batteries under lateral impact.

Frontline | EVE Energy''s large cylindrical batteries have been

Apr 26, 2025 · Although the large cylindrical battery has multiple advantages in new energy vehicle applications, its production process standards and requirements are also very strict.

Large cylindrical battery, the ultimate technical direction of

Apr 15, 2022 · Recently, at the power battery forum hosted by the China Electric Vehicle 100 People''s Association, power battery companies such as BAK Battery and Ewell Lithium

Analysis of Cylindrical Lithium Battery Advantages and

Among all lithium-ion batteries produced globally by lithium battery manufacturers, cylindrical lithium batteries have the highest degree of process standardization and are the earliest to

Thermal modeling of cylindrical batteries

Nov 9, 2017 · This post will serve as an introduction to heat transfer modeling of a cylindrical battery. A common form factor for lithium-ion cylindrical cells is

Deformation and failure properties of cylindrical battery

May 1, 2025 · Recently, Lithium-ion batteries have emerged as a preferred choice for electric vehicle manufacturer due to their high specific energy, excellent cycle performance, and

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Influence of cell dimensions and housing material on the

Jun 1, 2023 · The utilization of large-format cylindrical lithium-ion cells with innovative tab design has been confirmed by a number of automotive manufacturers for future vehicle generations.

4680 large cylinder: the potential direction of high-end lithium

Apr 20, 2022 4680 large cylinder: the potential direction of high-end lithium batteries, the development of industrialization is accelerated The 4680 large cylindrical battery improves

Numerical investigation of a cylindrical lithium-ion battery

Dec 1, 2023 · However, there have been few studies that incorporate rectangular liquid channels in a PCM battery module composed of a high number of cylindrical cells. In this work, a new

Predicting specific heat capacity and directional thermal

Jan 5, 2021 · This paper proposes a methodology to determine the specific heat capacity and the directional components of the thermal conductivity of cylindrical lithium-ion batteries (LIBs) by

Failure mechanisms and acoustic responses of cylindrical lithium

Sep 1, 2024 · High-SOC batteries experience higher forces and displacements at the failure point. High-capacity batteries have poor bearing capacity and are more prone to thermal runaway.

Direct cooling thermal management of cylindrical batteries

Apr 9, 2025 · For lithium-ion batteries, excessive temperature and nonuniform thermal distribution reduce stability, shorten service life, and may even lead to thermal runaway. To mitigate these

Experimental study on the vertical thermal runaway

Oct 1, 2021 · Nevertheless, lithium-ion batteries often appear in the form of modules in practical applications. When a single battery in the module undergoes thermal runaway, a large amount

Dynamic crushing behaviors and failure of cylindrical lithium

Dec 1, 2023 · The mechanical property and failure prediction play a significant role in engineering applications of lithium-ion batteries (LIBs), but with great difficulties due to their complicated

Failure Analyses of Cylindrical Lithium-Ion Batteries Under

Mar 17, 2025 · In this paper, taking the 18,650 lithium-ion battery cell as an example, a detailed model is established that includes five components which are the anode, cathode, separator,

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · This study presented an electrochemical-thermal model for cylindrical lithium-ion batteries, integrating a detailed multi-layer thermal framework with electrochemical dynamics.

Homogenized mechanical properties for the jellyroll of cylindrical

Nov 1, 2013 · Until recently the battery development was supported by testing alone. The present analysis provides a valuable contribution to the development of a reliable computational model

6 FAQs about [Cylindrical lithium batteries have direction]

Do cylindrical lithium-ion battery cells respond to impact?

We report on modeling response of cylindrical lithium-ion battery cells to impact. The proposed model was validated through experimental testing. Two homogenization methods for the jellyroll were developed. Experimental results showed a very good agreement with simulations.

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

How do you model a cylindrical lithium-ion battery?

For the modeling of cylindrical lithium-ion batteries, detailed structural models including cathode material, cathode material, diaphragms, and shells can more accurately react to battery deformation and faults, and determine the failure position, but usually require significant computational costs and the model is particularly complex.

Do cylindrical lithium-ion batteries exhibit deformation in only two directions?

However, this limitation has not been a central concern in the present study, as cylindrical lithium-ion batteries primarily exhibit deformation in only two directions. The focus of this paper is specifically on the most critical direction of the battery, during high-impact vehicle crashes, where lateral forces dominate.

Are cylindrical lithium-ion battery cells suitable for impact testing?

We report on modeling mechanical response of cylindrical lithium-ion battery cells that are commonly used in automotive applications when subjected to impact testing. The developed homogenized model that accurately captures mechanical response of a cell to lateral crash is reported.

Update Information

- Common models of cylindrical lithium batteries

- Balancing of cylindrical lithium batteries

- What are the types of small cylindrical lithium batteries

- How many types of cylindrical lithium batteries are there

- What are the small cylindrical lithium batteries

- Cylindrical lithium battery assembly process

- Georgia develops lithium batteries for energy storage

- That company needs lithium batteries for energy storage

- Is there a big relationship between energy storage and lithium batteries

- Can lithium batteries be used for global energy storage

- Why do 5G base stations use lithium iron phosphate batteries

- Lead-acid batteries and lithium batteries for inverters in Bulgaria

- Can lithium batteries be used as energy storage power stations

Solar Storage Container Market Growth

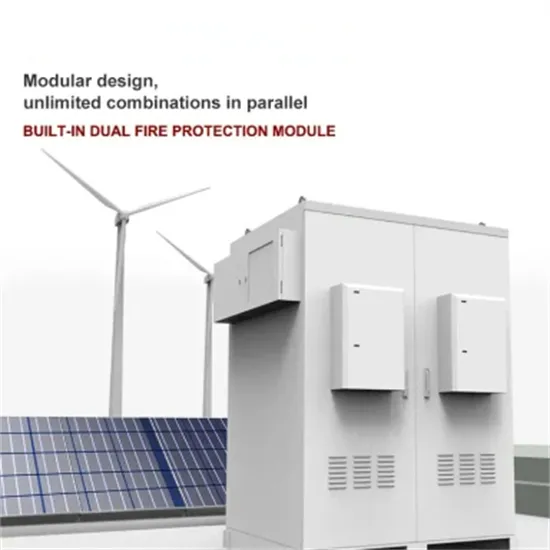

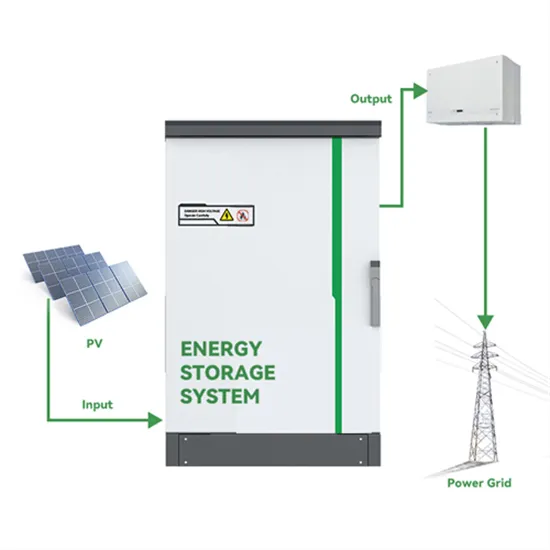

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

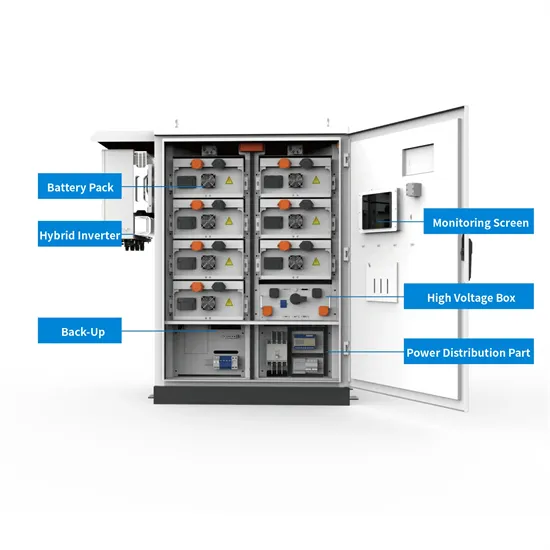

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.