Copenhagen Energy Storage Battery Price Trends: What You

Apr 18, 2025 · But in 2025, there''s a new star stealing the spotlight: energy storage battery prices. With major players like Canadian Solar''s subsidiary e-STORAGE landing multi-gigawatt-hour

How Much Does a 72V 100Ah Lithium Battery Pack Cost?

Jul 25, 2024 · The cost of a 72V 100Ah lithium battery pack typically ranges from $399 to $1,172, depending on various factors such as brand, specifications, and supplier. Understanding these

How much does a lithium battery pack cost

As the photovoltaic (PV) industry continues to evolve, advancements in How much does a lithium battery pack cost have become critical to optimizing the utilization of renewable energy

Battery Costs in 2020-2030: How Much Have Prices Dropped

Aug 6, 2025 · The price of batteries is one of the biggest factors affecting the growth of electric vehicles (EVs) and energy storage. Over the past decade, battery prices have fallen

How much does a lithium-ion battery pack cost?

The cost of a lithium-ion battery pack can vary widely. On average, a lithium-ion battery pack for an electric vehicle can range from $5,000 to $15,000, depending on the vehicle''s size and

Danish Lithium Battery Pack Cost Pricing Trends and Key

Lithium battery packs have become the backbone of Denmark''s green transition, powering everything from residential solar systems to industrial energy storage. But how much does a

Average pack price of lithium-ion batteries and share of

Jul 2, 2025 · Average pack price of lithium-ion batteries and share of cathode material cost, 2011-2021 - Chart and data by the International Energy Agency.

Which lithium battery is cheaper in copenhagen

Lithium-ion batteries are one of the most efficient energy storage devices worldwide. Over recent years,high-scale production and capital investment into the battery production process made

Lithium Battery Cost: Is It Worth the Higher

Jul 31, 2025 · Yes, Lithium battery cost is worth it due to its higher lifespan, better capacity, lesser maintenance, higher energy density, and better performance.

How Much Does A 100kWh Battery Cost?

May 26, 2025 · 100kWh battery systems typically cost between $10,000 and $30,000, depending on chemistry, application, and scale. Lithium-ion variants like NMC or LiFePO4 dominate the

How does the cost of lithium-ion batteries vary

Nov 6, 2024 · China Lowest Prices: China typically offers the lowest lithium-ion battery prices globally. In 2023, average battery pack prices in China were

How Much Is a New Tesla Battery Pack? Cost Breakdown

Jun 24, 2025 · With its innovative technology and sleek designs, Tesla has become a household name, and its battery packs are a crucial component of its electric vehicles. But have you ever

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Electric Car Battery Pack Costs: How Much They Are And

Mar 27, 2025 · The cost of an electric car battery pack varies widely. Replacement costs range from $4,000 to $20,000, depending on the manufacturer''s specifications.

How Much Do Lithium-Ion Batteries Cost? An Insight into

Feb 21, 2025 · Lithium-ion batteries are crucial for various applications, including electric vehicles (EVs) and renewable energy storage systems. Understanding their pricing dynamics is

How much does Beijing energy storage battery pack cost

Oct 6, 2024 · When evaluating cost, it''s essential to note that while lithium-ion systems present a larger initial investment, their superior performance and longevity often yield a more favorable

Lithium-Ion Battery Pack Prices See Largest Drop Since

Dec 10, 2024 · Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors

How Much Is An Electric Car Battery Pack? Cost Breakdown

Mar 29, 2025 · The cost of an electric car battery pack is a complex topic, influenced by several factors, including the type of battery chemistry, the size and capacity of the battery, the

6 FAQs about [How much does the Copenhagen lithium battery pack cost]

How much does a lithium nickel cobalt battery cost?

Lithium nickel cobalt aluminum oxide (NCA) battery cells have an average price of $120.3 per kilowatt-hour (kWh), while lithium nickel cobalt manganese oxide (NCM) has a slightly lower price point at $112.7 per kWh. Both contain significant nickel proportions, increasing the battery’s energy density and allowing for longer range.

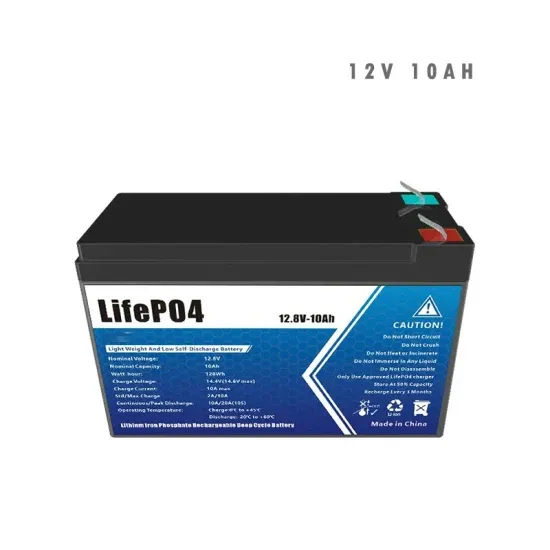

How much does a lithium phosphate battery cost?

At a lower cost are lithium iron phosphate (LFP) batteries, which are cheaper to make than cobalt and nickel-based variants. LFP battery cells have an average price of $98.5 per kWh. However, they offer less specific energy and are more suitable for standard- or short-range EVs.

Why did lithium-ion battery prices drop 20% from 2023?

Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors driving the decline include cell manufacturing overcapacity, economies of scale, low metal and component prices, adoption of lower-cost lithium-

How much does a battery cost?

This specific composition is pivotal in establishing the battery’s capacity, power, safety, lifespan, cost, and overall performance. Lithium nickel cobalt aluminum oxide (NCA) battery cells have an average price of $120.3 per kilowatt-hour (kWh), while lithium nickel cobalt manganese oxide (NCM) has a slightly lower price point at $112.7 per kWh.

How much does an 80 kWh battery cost?

A more popular 80-kWh pack would be $11,120. Considering a $35,000-$40,000 price tag for a car, it's still a substantial part of the price, but let's also recall that over 10 years ago, in a similar bracket, we would get only an EV with a 24-30-kWh battery and a few times shorter driving range.

How much does an EV battery pack cost?

Depending on the brand and model of the vehicle, the cost of a new lithium-ion battery pack might be as high as $25,000: The price of an EV battery pack can be shaped by various factors such as raw material costs, production expenses, packaging complexities, and supply chain stability. One of the main factors is chemical composition.

Update Information

- How much does it cost to balance a 60v lithium battery pack

- How much does it cost to replace a lithium battery station cabinet in Sierra Leone

- How much is the lithium iron phosphate battery pack

- Gb31241 How much can I buy a lithium battery pack

- How long does it take to customize a lithium battery pack

- How to prepare lithium battery pack

- Lithium battery pack production cost

- Multi-purpose lithium battery pack

- How much does it cost to customize a battery cabinet and battery rack

- Maputo lithium battery pack

- Lithium battery pack bl2409-ex

- Colombia graphite lithium battery pack

- Lima Power Lithium Battery Pack Processing

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.