BloombergNEF: Lithium-ion battery pack prices see largest

Dec 10, 2024 · Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis

The battery industry has entered a new phase –

Mar 5, 2025 · At the same time, the average price of a battery pack for a battery electric car dropped below USD 100 per kilowatt-hour, commonly thought of

Lithium-Ion Battery Pack Prices See Largest Drop Since

Dec 10, 2024 · Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs are commonly designed and manufactured in a pack–module–cell structure as schematically depicted in Fig. 2. The actual designs differ

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy consumption based on the

Electric vehicle battery prices are expected to fall

Oct 7, 2024 · Our researchers forecast that average battery prices could fall towards $80/kWh by 2026, amounting to a drop of almost 50% from 2023, a

How Manufacturer Can Tell You About Cost of

Jun 6, 2024 · Why are lithium batteries more expensive than other batteries? Ufine, as a battery factory, will tell you all about the cost of lithium batteries.

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Costs, carbon footprint, and environmental impacts of lithium

Jan 1, 2024 · Strong growth in lithium-ion battery (LIB) demand requires a robust understanding of both costs and environmental impacts across the value-chain. Rece

Cost modeling for the GWh-scale production of modern lithium

Abstract Battery production cost models are critical for evaluating the cost competitiveness of different cell geometries, chemistries, and production processes. To address this need, we

FOTW #1272, January 9, 2023: Electric Vehicle

Jun 20, 2017 · The Department of Energy''s (DOE''s) Vehicle Technologies Office estimates the cost of an electric vehicle lithium-ion battery pack declined 89%

Trends in batteries – Global EV Outlook 2023 –

Aug 19, 2025 · The increase in battery demand drives the demand for critical materials. In 2022, lithium demand exceeded supply (as in 2021) despite the

Battery cost modeling: A review and directions for future

Jul 1, 2020 · By assessing battery-pack costs under set production volumes, it can be used to predict material and energy demands as well as to identify opportunities for cost reductions.

Lithium-Ion Battery Costs: Manufacturing Prices,

Mar 16, 2025 · The cost to make lithium-ion batteries ranges from $40 to $140 per kWh. Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or the West.

Understanding Lithium-Ion Battery Costs: A Complete

Feb 10, 2025 · Lithium-ion batteries (Li-ion) have become a crucial component in powering our modern lives—from the smartphones in our pockets to electric vehicles on the streets. While

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

Cost modeling for the GWh-scale production of modern lithium

Nov 3, 2024 · Battery production cost models are critical for evaluating the cost competitiveness of different cell geometries, chemistries, and production processes. To address

Techno-economic analysis of lithium-ion battery price

Nov 1, 2023 · As of today, several researchers have developed learning curve–based models for battery price (or cost) projections. This techno-economic analysis method is widely embraced

Electric vehicle economics: How lithium-ion

Nov 5, 2024 · Electric vehicle economics: How lithium-ion cell costs impact EV prices Lithium prices have fallen significantly, putting the cost of cells at 7.5%

What are the projected cost reductions for battery storage

Feb 16, 2025 · The battery pack component is expected to see the largest share of cost reductions compared to balance of system and installation components. Global manufacturing

Update Information

- 12v1 3a lithium battery pack production

- Production of lithium iron phosphate battery pack

- How much does the Copenhagen lithium battery pack cost

- How much does it cost to balance a 60v lithium battery pack

- Production of lithium battery pack types

- Tanzania electric sanitation vehicle lithium battery pack

- 450W motor lithium battery pack

- New Delhi special-shaped lithium battery pack

- How much does it cost to replace a lithium battery station cabinet in Sierra Leone

- Bogota 3000-5000mah lithium battery pack

- Hanoi lithium battery pack

- Low temperature charging of lithium battery pack

- Lithium iron phosphate battery pack product introduction

Solar Storage Container Market Growth

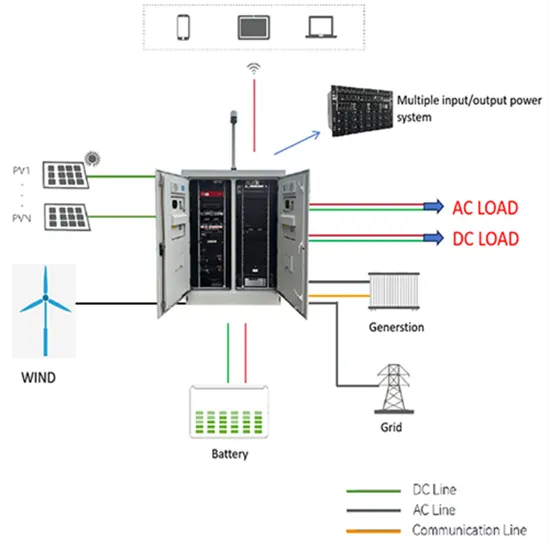

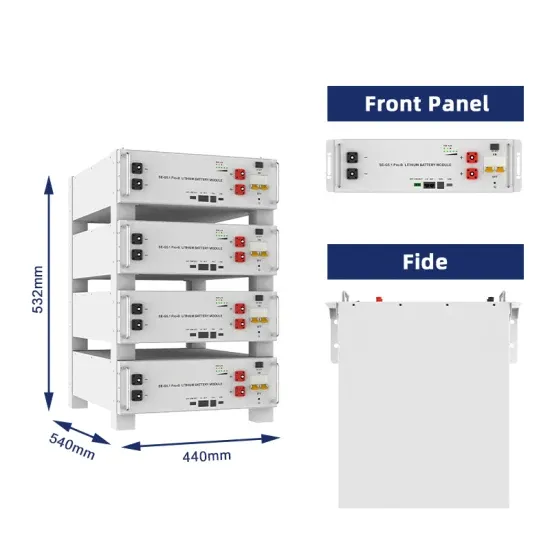

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

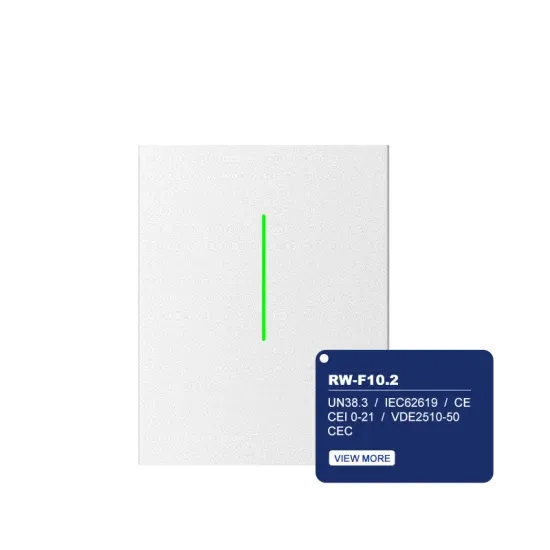

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.