SECTION 5: FLOW BATTERIES

Jun 14, 2022 · The pump runs and requires power during both charge and discharge, so, 𝐸𝐸𝑝𝑝𝑝𝑝𝑚𝑚,𝑖𝑖𝑛𝑛=𝑝𝑝∫0 𝑠𝑠𝑐𝑐+𝑠𝑠𝑑𝑑𝑃𝑃

''Magic Applications'' and Commercial Realities: Flow Battery

Jul 10, 2019 · Flow batteries have had part of their pedigree in transport applications – some early zinc-bromine and vanadium systems were used in cars and golf carts. With low-cost

Vanadium batteries

Jan 1, 2021 · The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

Research on Performance Optimization of Novel

Oct 6, 2023 · The all-vanadium flow batteries have gained widespread use in the field of energy storage due to their long lifespan, high efficiency, and safety

Pump Fault Diagnosis of All-Vanadium Liquid Flow

Apr 11, 2025 · In this paper, an all-vanadium liquid flow battery pump fault diagnosis method based on NPSO-SVM is explored and experimentally validated. The experimental outcomes

Prospects for industrial vanadium flow batteries

Jul 15, 2023 · Building on the experiences gained at the Electrochemical Energy Storage and Conversion Lab (EESCoLab) at the University of Padova (Italy) and on pertinent scientific

全钒液流电池在充电结束搁置阶段的开路电压变化

Nov 7, 2022 · Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate the open-circuit voltage change during the shelving phase. It is discovered that the open-circuit

Large Flow Rate All Vanadium Electrolyte Magnetic Circulation Pump

Find verified Large Flow Rate All Vanadium Electrolyte Magnetic Circulation Pump for Liquid Flow Battery suppliers and manufacturers offering competitive wholesale prices. Browse detailed

Sichuan V-LiQuid Energy Co., Ltd.

V-Liquid is a developer and manufacturer specializing in all-vanadium flow battery technology. We focus on the research, development, production, and sales of core materials, electric stacks,

Towards a high efficiency and low-cost aqueous redox flow battery

May 1, 2024 · The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow batteries,

electrochemical energy Storage

May 25, 2020 · True redox, where all the chemical species active in storing energy are fully dissolved in solution at all times (vanadium/vanadium, iron/chromium). Hybrid redox, where at

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · Compared with the all-vanadium flow battery, since the vanadium/air single flow battery uses an air/oxygen diffusion electrode to replace the flow positive half-cell, the amount

Dynamic modeling of all-vanadium flow battery

The model is applied to study the effects of current, electrolyte flow rate and temperature on the charge and discharge characteristics. Key words: all-vanadium flow battery, dynamic model,

Research progress in preparation of electrolyte for all-vanadium

Feb 25, 2023 · All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Pump Fault Diagnosis of All-Vanadium Liquid Flow Battery

Apr 12, 2025 · In this paper, an all-vanadium liquid flow battery pump fault diagnosis method based on NPSO-SVM is explored and experimentally validated. The experimental outcomes

An Open Model of All-Vanadium Redox Flow Battery Based

Oct 19, 2021 · Based on the component composition and working principle of the all-vanadium redox flow battery (VRB), this paper looks for the specific influence mechanism of the

Haiti all-vanadium liquid flow energy storage pump

The all-vanadium flow batteries have gained widespread use in the field of energy storage due to their long lifespan, high efficiency, and safety features. However, in order to further advance

Liquid Flow Battery Energy Storage Circulating Pump for Vanadium

Aug 19, 2025 · Liquid Flow Battery Energy Storage Circulating Pump for Vanadium Electrolyte Transfer, Find Details and Price about Electrolyte Pump Electrolyte Transfer Pump from Liquid

doha haiti all-vanadium liquid flow energy storage pump

A comparative study of iron-vanadium and all-vanadium flow battery for large scale energy storage A typical case of a 1 MW/4h flow battery system is selected for the comparison of

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Vanadium batteries are mainly composed of electrolyte, electrodes, selective proton exchange membranes, bipolar plates and fluid collectors. Among them, the electrolyte

A novel flow design to reduce pressure drop and enhance

Feb 1, 2025 · The Vanadium Redox Flow Battery (VRFB) is one of the promising stationary electrochemical storage systems in which flow field geometry is essential to ensure uniform

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

Liquid Flow Batteries: Principles, Applications, and Future

Jun 16, 2024 · Abstract. This paper aims to introduce the working principle, application fields, and future development prospects of liquid flow batteries. Fluid flow battery is an energy storage

Vanadium Flow Battery: How It Works and Its Role in Energy

Mar 3, 2025 · A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion exchange happens

6 FAQs about [All-vanadium liquid flow battery pump in Lyon France]

Why are vanadium redox flow battery systems important?

Battery storage systems become increasingly more important to fulfil large demands in peaks of energy consumption due to the increasing supply of intermittent renewable energy. The vanadium redox flow battery systems are attracting attention because of scalability and robustness of these systems make them highly promising.

Why does a vanadium electrolyte deteriorate a battery membrane?

Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor membrane selectivity towards vanadium permeability can lead to faster discharge times of the battery. These areas seek room for improvement to increase battery lifetime.

Can polymeric membranes be used in vanadium redox flow batteries (VRB)?

This review on the various approaches to prepare polymeric membranes for the application in Vanadium Redox Flow Batteries (VRB) reveals various factors which should be considered when developing new membranes materials with or without the addition of non-polymeric materials.

How durable is a vanadion membrane in multiple charge/discharge cycling?

Also, the electrolyte utilization increases from 54.1% to 68.4%, even at a high current density of 240 mA•cm−2 . Moreover, the durability of the hybrid VANADion membrane in multiple charge/discharge cycling was shown to be similar to that of Nafion 115 and VANADion over the 80–240 mA•cm −2 current density range .

Why do cell membranes suffer from cross-mixing of vanadium ions?

However, they suffer from the cross-mixing of vanadium ions. The membrane has the important task to transfer the charge balancing species between the half cells, at the same time to be selective enough to separate Vanadium species, where their mixing leads to auto battery discharge [75, 113].

Why do Nafion membranes have a lower vanadium ion crossover rate?

In this way a cationic charged layer can formed on the surface of Nafion which is strongly bonded to the Nafion surface. As a result of the repulsive layer the membrane showed a lower vanadium ion crossover rate, at the cost of a higher area resistance.

Update Information

- Estonian all-vanadium liquid flow battery electrolyte

- New all-vanadium liquid flow battery

- Marshall Islands UET All-Vanadium Liquid Flow Battery

- Reduction-oxidation all-vanadium liquid flow battery

- All-vanadium liquid flow energy storage battery project

- El Salvador s new all-vanadium flow battery electrolyte pump

- All-vanadium liquid flow battery has

- Characteristics of all-vanadium liquid flow battery

- Liquid flow energy storage battery configuration

- Thailand liquid flow battery materialization

- New Delhi Liquid Flow Battery Brand Ranking

- Liquid Flow Battery Company

- 1000 degree vanadium liquid flow battery

Solar Storage Container Market Growth

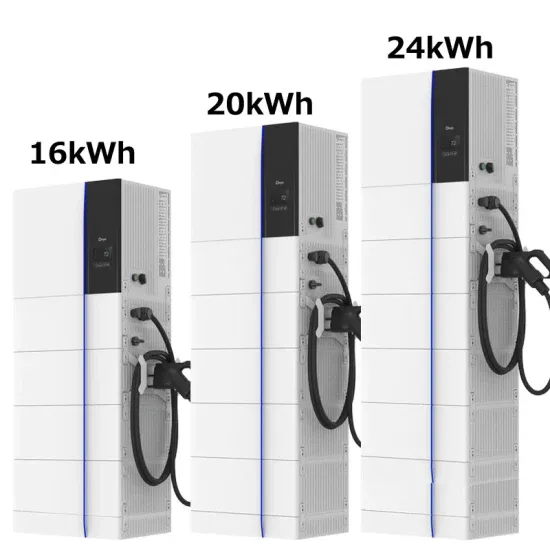

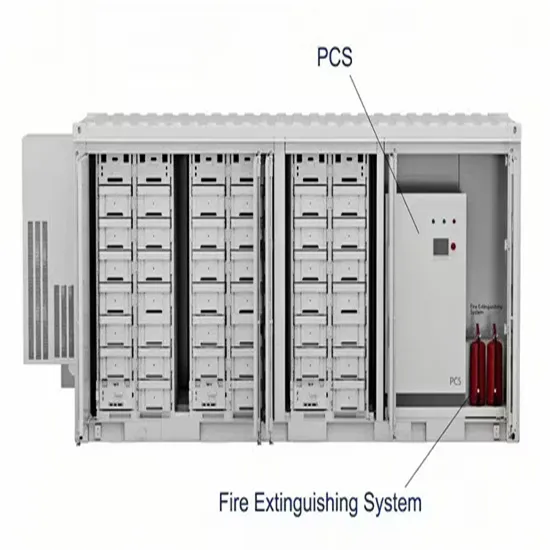

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

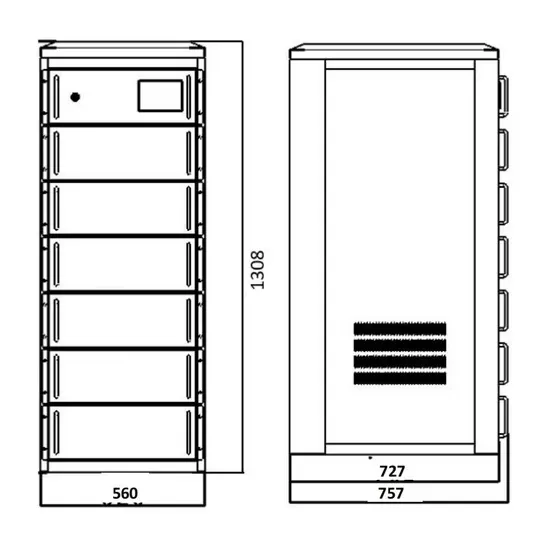

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.