Principle, Advantages and Challenges of Vanadium Redox Flow Batteries

Nov 26, 2024 · Circulating Flow Batteries offer a scalable and efficient solution for energy storage, essential for integrating renewable energy into the grid. This study evaluates various

Vanadium Electrolyte Studies for the Vanadium

Jun 13, 2016 · Graphical Abstract How do your electrons flow? The properties of the vanadium redox flow battery electrolyte vary with supporting electrolyte

Preparation of vanadium flow battery electrolytes: in-depth

Jul 10, 2025 · In this context, this article summarizes several preparation methods for all-vanadium flow battery electrolytes, aiming to derive strategies for producing high

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Abstract Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The

Liquid flow batteries are rapidly penetrating into hybrid

Oct 12, 2024 · Liquid flow batteries are rapidly penetrating into hybrid energy storage applications-Shenzhen ZH Energy Storage - Zhonghe LDES VRFB - Vanadium Flow Battery Stacks -

A highly concentrated vanadium protic ionic liquid electrolyte

Jun 1, 2021 · A protic ionic liquid is designed and implemented for the first time as a solvent for a high energy density vanadium redox flow battery. Despite being less conductive than standard

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · Compared with the all-vanadium flow battery, since the vanadium/air single flow battery uses an air/oxygen diffusion electrode to replace the flow positive half-cell, the amount

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

A review of bipolar plate materials and flow field designs in the all

Apr 1, 2022 · A bipolar plate (BP) is an essential and multifunctional component of the all-vanadium redox flow battery (VRFB). BP facilitates several functions in the VRFB such as it

Preparation of vanadium flow battery electrolytes: in-depth

Jul 10, 2025 · The preparation technology for vanadium flow battery (VRFB) electrolytes directly impacts their energy storage performance and economic viability. This review analyzes

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor

全钒液流电池在充电结束搁置阶段的开路电压变化

Dec 30, 2021 · The experimental results demonstrated that the slow rise of the open-circuit voltage of the all-vanadium liquid flow battery is related to the

estonia vanadium liquid flow energy storage battery

Construction has begun on a facility which will make electrolyte for vanadium flow batteries in South Africa''''s Eastern Cape, by vertically-integrated vanadium producer Bushveld Minerals.

全钒液流电池的电极结构研究进展

Jul 22, 2024 · 全钒液流电池 (VRFB)作为一种极具前途的大规模储能技术,提高电池功率密度和运行效率是降低液流电池成本的有效途径之一。 电极是实现电能与化学能相互转换的核心场

A Wide-Temperature-Range Electrolyte for all Vanadium Flow Batteries

Jun 4, 2025 · This study proposes a wide-temperature-range (WTR) electrolyte by introducing four organic/inorganic additives, comprising benzene sulfonate, phosphate salts, halide salts, and

What is all-vanadium liquid flow battery energy storage?

Feb 11, 2024 · The all-vanadium liquid flow battery represents a sophisticated and innovative approach to energy storage, characterized by its unique mechanism that utilizes vanadium

China to host 1.6 GW vanadium flow battery

Sep 23, 2024 · The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

Vanadium Battery | Energy Storage Sub-Segment – Flow Battery

Jun 30, 2025 · After the energy storage system is scrapped, the vanadium electrolyte solution can be recycled and reused, with a high residual value and will not cause pollution to the

Review—Preparation and modification of all‐vanadium

Feb 15, 2025 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Measuring density and viscosity of vanadium electrolytes: A

Jul 30, 2024 · The variation of the physical properties of vanadium electrolytes during vanadium redox flow batteries (VRFB) operation is known to have a significant impact on the flow of the

A review of transport properties of electrolytes in redox flow

Feb 1, 2025 · Therefore, the electrolyte is one of the most important components in redox flow batteries and its physicochemical properties greatly determine the battery performance. Here,

Sustainable recycling and regeneration of redox flow battery

Feb 1, 2025 · As the demand for large-scale sustainable energy storage grows, redox flow batteries (RFBs), particularly all-vanadium RFBs (VRFBs), have emerged as a promising

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Electrolysis is currently the mainstream preparation method, using vanadium pentoxide as the raw material, produced in sulphuric acid, the operating temperature is

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · Electrolyte utilization and the consequent concentration polarization significantly limit the potential increase in power density and contribute to electrode degradation in

6 FAQs about [Estonian all-vanadium liquid flow battery electrolyte]

What is a Commercial electrolyte for vanadium flow batteries?

Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and phosphate concentrations in the range from 1.4 to 1.7 m, 3.8 to 4.7 m, and 0.05 to 0.1 m, respectively, are prepared.

What is the ideal electrolyte for vanadium batteries?

The ideal electrolyte for vanadium batteries needs to ensure the stability of high-concentration vanadium ions in different oxidation states over a wide temperature range. A key issue to be resolved is to improve the stability of V 5+ at high temperatures (50 °C) and V 3+ at low temperatures (−5 °C).

How important is the vanadium electrolyte preparation process?

In conclusion, the concentration of vanadium, sulfuric acid and impurities in the vanadium electrolyte are very important for the operation of the VRFB. Therefore, the vanadium electrolyte preparation process needs to be continuously optimized to meet the requirements of the VRFB. Table 2.

What is the best electrochemical performance of vanadium electrolyte?

In a word, the best electrochemical performance of vanadium electrolyte was obtained with 3.0 M vanadium, 5.7 M chloride (V: Cl = 1:1.9) and 2.8 M sulfate. 3.3. Single cell performance of the VRFB

What is a single vanadium element battery?

Their single vanadium element system avoids capacity fading caused by crossover contamination in iron-chromium flow batteries (ICFBs) . Additionally, VRFBs use an aqueous electrolyte, eliminating the safety risks associated with bromine vapor corrosion in zinc-bromine flow batteries (ZBFBs) .

Can ion transport improve vanadium redox flow battery electrolytes?

Furthermore, research progress in other battery fields shows that optimizing electrolyte formulations [21, 22] and ion transport [23, 24] can significantly enhance energy density and cycling stability, providing valuable insights for improving vanadium redox flow battery electrolytes. Table 1.

Update Information

- Huawei Sri Lanka all-vanadium liquid flow battery

- Characteristics of all-vanadium liquid flow battery

- El Salvador s new all-vanadium flow battery electrolyte pump

- All-vanadium liquid flow energy storage battery project

- New all-vanadium liquid flow battery

- All-vanadium liquid flow battery pump in Lyon France

- Marshall Islands UET All-Vanadium Liquid Flow Battery

- Togo All-vanadium Liquid Flow Battery

- Long-lasting zinc-bromine non-attenuation liquid flow energy storage battery

- Liquid Flow Battery Iron

- Vanadium Liquid Flow Battery Metal Research Institute

- Leading enterprise of vanadium liquid flow energy storage battery

- Vientiane Electric Power Construction Zinc-Iron Liquid Flow Battery

Solar Storage Container Market Growth

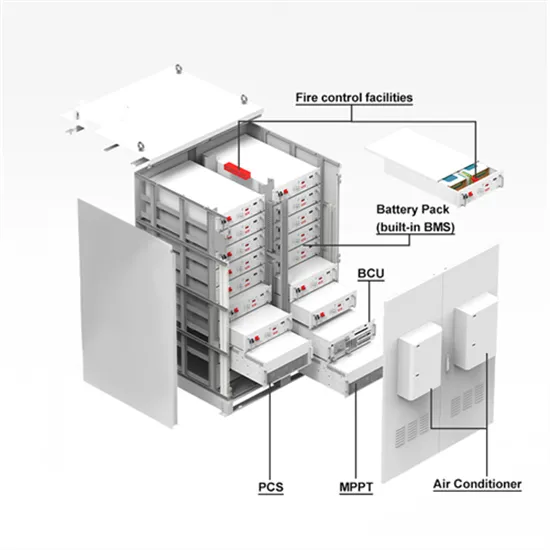

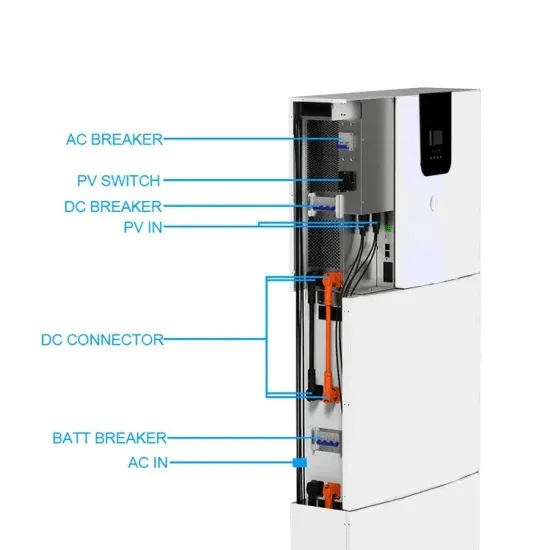

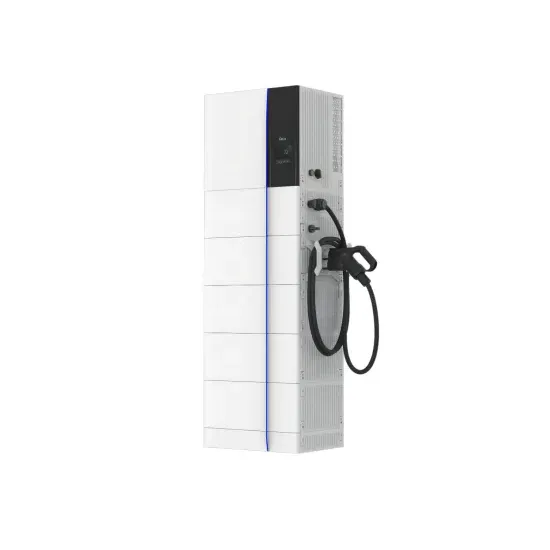

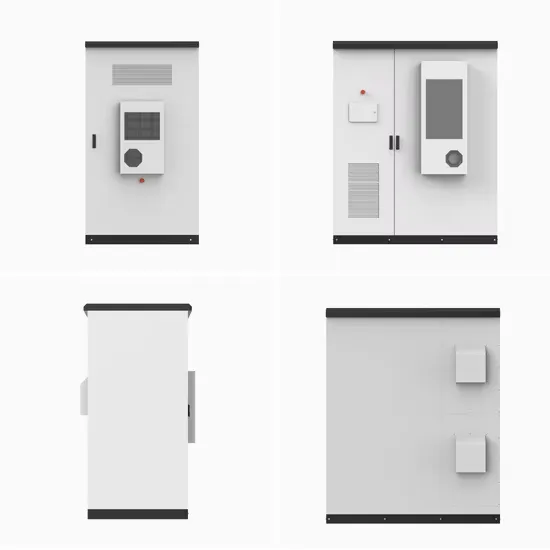

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

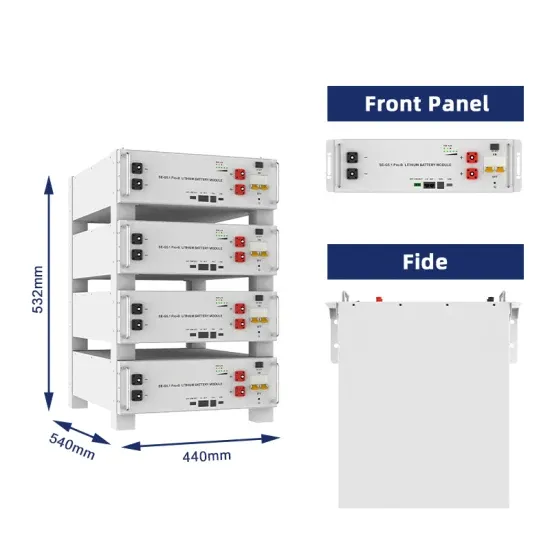

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.