A Bifunctional Liquid Fuel Cell Coupling Power

Apr 20, 2023 · All vanadium flow batteries (VFBs) are considered one of the most promising large-scale energy storage technology, but restricts by the high

全钒液流电池在充电结束搁置阶段的开路电压变化

Nov 7, 2022 · Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate the open-circuit voltage change during the shelving phase. It is discovered that the open-circuit

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Abstract Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The

All vanadium liquid flow energy storage enters the GWh era!

Jun 19, 2025 · On the afternoon of October 30th, the world''s largest and most powerful all vanadium flow battery energy storage and peak shaving power station (100MW/400MWh) was

What is all-vanadium liquid flow battery energy storage?

Feb 11, 2024 · The all-vanadium liquid flow battery represents a sophisticated and innovative approach to energy storage, characterized by its unique mechanism that utilizes vanadium

Advancing Flow Batteries: High Energy Density

Dec 17, 2024 · A high-capacity-density (635.1 mAh g − ¹) aqueous flow battery with ultrafast charging (<5 mins) is achieved through room-temperature liquid

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

A review of bipolar plate materials and flow field designs in the all

Apr 1, 2022 · A bipolar plate (BP) is an essential and multifunctional component of the all-vanadium redox flow battery (VRFB). BP facilitates several functions in

China to host 1.6 GW vanadium flow battery

Sep 23, 2024 · The all-vanadium liquid flow industrial park project is taking shape in the Baotou city in the Inner Mongolia autonomous region of China, backed

Weifang Built The First 1MW/4MWh Hydrochloric Acid-based All-Vanadium

Jul 4, 2022 · On July 1, the first phase of the first hydrochloric acid-based all-vanadium liquid flow energy storage power station in China was successfully completed in Weifang Binhai

Pump Fault Diagnosis of All-Vanadium Liquid Flow Battery

Apr 12, 2025 · In recent years, the all-vanadium flow battery (VRFB) has demonstrated a notable trajectory of advancement as a large-scale, long-life energy storage technology, characterised

All-Vanadium Liquid Flow Energy Storage System: The

Sep 14, 2023 · Now meet vanadium flow systems: the marathon runners of energy storage. Here''s why they''re stealing the spotlight: China''s Dalian Flow Battery Demonstration Project

Research on Performance Optimization of Novel

Oct 6, 2023 · Therefore, this paper aims to explore the performance optimization of all-vanadium flow batteries through numerical simulations. A mathematical

Vanadium batteries

Jan 1, 2021 · The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

An Open Model of All-Vanadium Redox Flow Battery Based

Oct 19, 2021 · Influence mechanism, based on MATLAB/Simulink to build an open VRB model, mainly around the four key components of the all-vanadium flow battery. This model has

A Wide‐Temperature‐Range Electrolyte for all Vanadium Flow Batteries

Jun 4, 2025 · The all-vanadium flow battery (VFB) has emerged as a highly promising large-scale, long-duration energy storage technology due to its inherent advantages, including decoupling

Vanadium Battery | Energy Storage Sub-Segment – Flow Battery

Jun 30, 2025 · All-vanadium flow battery, full name is all-vanadium redox battery (VRB), also known as vanadium battery, is a type of flow battery, a liquid redox renewable battery with

Technology Strategy Assessment

Jan 12, 2023 · Background Introduction Redox flow batteries (RFBs) or flow batteries (FBs)—the two names are interchangeable in most cases—are an innovative technology that offers a

Pump Fault Diagnosis of All-Vanadium Liquid Flow

Apr 11, 2025 · Abstract. In recent years, the all-vanadium flow battery (VRFB) has demon-strated a notable trajectory of advancement as a large-scale, long-life energy stor-age technology,

What is all-vanadium liquid flow battery energy storage?

Feb 11, 2024 · What is all-vanadium liquid flow battery energy storage? 1. All-vanadium liquid flow batteries utilize a unique electrochemical process for energy storage, specifically leveraging

全钒液流电池在充电结束搁置阶段的开路电压变化

Dec 30, 2021 · 关键词: 全钒液流电池, 开路电压, 非液流储能电池 Abstract: Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate

Vanadium redox flow battery: Characteristics and

Apr 30, 2024 · As a new type of green battery, Vanadium Redox Flow Battery (VRFB) has the advantages of flexible scale, good charge and discharge performance and long life.

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Vanadium batteries are mainly composed of electrolyte, electrodes, selective proton exchange membranes, bipolar plates and fluid collectors. Among them, the electrolyte

6 FAQs about [All-vanadium liquid flow battery has]

What membranes are used in vanadium flow batteries?

The membranes employed in vanadium flow batteries can be grouped into ion exchange membranes and physical separators; however, this topic will only focus on ion exchange membranes .

What happens if a battery is contaminated with vanadium?

The cross-contamination of vanadium can cause self-discharge of the battery due to spontaneous disproportionation equilibria between V (V) and V (II) to produce V (III) or V (IV), V (V) and V (III) to produce V (IV), and V (IV) and V (II) to obtain (VIII) as described in Eqs. (4), (5), (6), (7).

Which chemistry is best for redox flow batteries?

The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it utilizes four stable redox states of vanadium. This chapter reviews the state of the art, challenges, and future outlook for all-vanadium redox flow batteries. 1.

What are all-vanadium redox flow batteries?

All-vanadium redox flow batteries use V (II), V (III), V (IV), and V (V) species in acidic media. This formulation was pioneered in the late eighties by the research group of Dr Maria Skyllas-Kazacos as an alternative to the Fe/Cr chemistry originally proposed by NASA.

Which chemistries expand the voltage range of vanadium?

A series of chemistries based on Zn, Fe, Cu, Br, Cr, Ru, or organic redox active compounds, the redox potentials fo which expand the voltage range of vanadium, have been studied in ILs to leverage the high electrochemical stability of ILs , .

Who invented all-vanadium redox flow batteries?

Skyllas-Kazacos et al. developed the all-vanadium redox flow batteries (VRFBs) concept in the 1980s . Over the years, the team has conducted in-depth research and experiments on the reaction mechanism and electrode materials of VRFB, which contributed significantly to the development of VRFB going forward , , .

Update Information

- New all-vanadium liquid flow battery

- Marshall Islands UET All-Vanadium Liquid Flow Battery

- Reduction-oxidation all-vanadium liquid flow battery

- Huawei Sri Lanka all-vanadium liquid flow battery

- All-vanadium liquid flow energy storage battery project

- Characteristics of all-vanadium liquid flow battery

- 1000 degree vanadium liquid flow battery

- Liquid flow battery for 5G communication base station in Windhoek

- Liquid Flow Battery Company

- Vanadium Liquid Flow Battery Metal Research Institute

- Vientiane Electric Power Construction Zinc-Iron Liquid Flow Battery

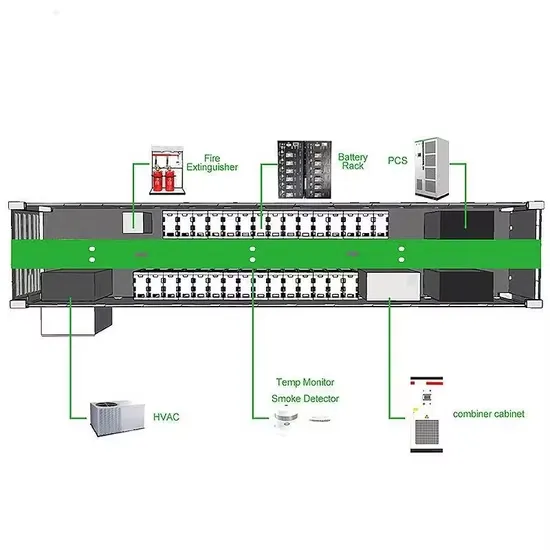

- Liquid Flow Battery Energy Storage Container

- Long-lasting zinc-bromine non-attenuation liquid flow energy storage battery

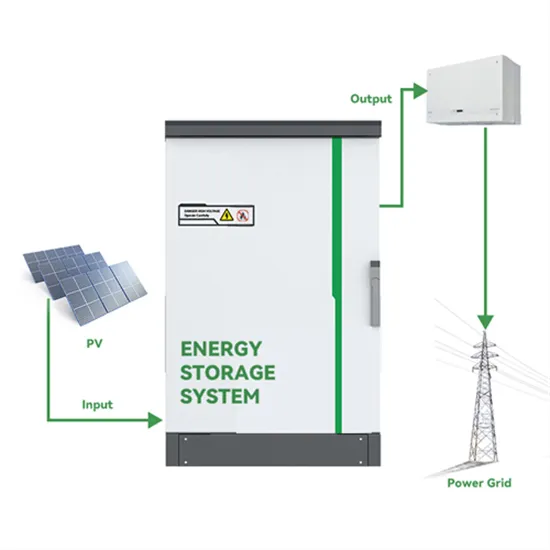

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

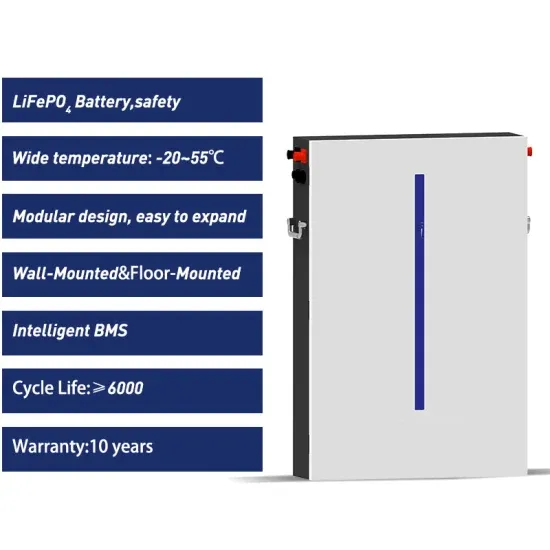

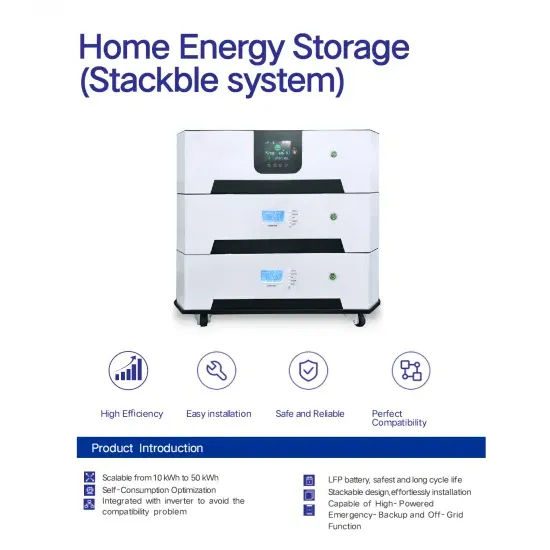

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.