Health and Safety Concerns of Photovoltaic Solar Panels

The solar panels proposed for use in the Oregon Department of Transportation''s Solar Highway program feature domestically manufactured and assembled monocrystalline silicon modules.

What you need to know about polysilicon and

Oct 13, 2021 · Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Crystalline silicon PV technology is the most commonly used type of photovoltaic technology and is known for its high efficiency and durability.

Solar Photovoltaic Technology Basics | NREL

Mar 25, 2025 · Photovoltaics (often shortened as PV) gets its name from the process of converting light (photons) to electricity (voltage), which is called the photovoltaic effect. This

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Solar PV Manufacturing Basics Explained

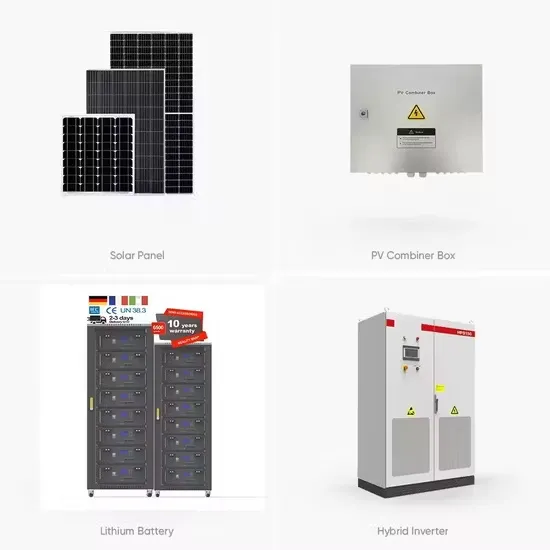

2 days ago · Solar photovoltaic (PV) manufacturing is the foundation of today''s clean energy revolution. From PV module manufacturing to racking systems and power electronics, each

Application of Silicone Sealant in Solar Modules

Jul 5, 2022 · A complete set of solar photovoltaic modules is roughly composed of seven parts: tempered glass, EVA film, solar cell, back sheet, aluminum alloy

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · In the photovoltaic supply chain, a substantial amount of photovoltaic secondary silicon-containing resource (PV-SSCR), including metallurgical-grade silicon refined slag

Material study of photovoltaic modules with silicone

Sep 15, 2021 · Old internal Dow Corning technical reports indicate that one silicone encapsulant material, called SYLGARD™1 184 Silicone Encapsulant, was a very common material used in

What kind of silicon is used in solar photovoltaic

Jun 19, 2024 · Silicon is primarily categorized into three types utilized in solar photovoltaic panels: monocrystalline silicon, polycrystalline silicon, and

Why Silicon Remains the Top Choice for Solar

Dec 20, 2024 · Over the last five years, the global expansion of photovoltaic (PV) capacity has further driven down the cost of crystalline silicon solar panels to

Which element is used in a solar cell? What is

May 13, 2015 · Photovoltaic panels can be built with amorphous or crystalline silicon. Solar cell efficiencies depend on the silicon configuration. In general,

Socio-Economic and Environmental Impacts of Silicon Based Photovoltaic

Jan 1, 2013 · These potential problems seem to be strong barriers for a further dissemination of PV technologies. Conventional PV (silicon based) manufacturing processes have roots in the

Why Silicon is the Most Widely Used Material in

May 15, 2024 · Silicon is found in 95% of solar modules today, showing its key role in solar energy. What makes silicon so important for the solar industry?

Comprehensive review on uses of silicon dioxide in solar cell

Jan 1, 2023 · This operation of silicon with one percent contamination silicon proceeds is applicable in numerous diligences but not the solar cell assiduity. Numerous nations contribute

6 FAQs about [Photovoltaic silicon is solar panels]

What is a silicon solar cell?

A silicon solar cell is a photovoltaic cell made of silicon semiconductor material. It is the most common type of solar cell available in the market. The silicon solar cells are combined and confined in a solar panel to absorb energy from the sunlight and convert it into electrical energy.

Are silicon photovoltaic cells a good choice for solar panels?

Silicon photovoltaic cells have achieved high efficiency levels, making them a reliable and efficient choice for solar energy generation. The material’s semiconductor properties contribute to this high efficiency, making it the preferred option for solar panels. 3. Durability and reliability

Is silicon a good material for solar panels?

Silicon is abundant in nature, making it a cost-effective and readily available material for photovoltaic cells. With its abundance, the production and scalability of silicon-based solar panels are facilitated, driving down the cost of solar energy. Silicon can be sourced from silica, found in sand, quartz, and other materials.

How are solar PV cells made?

Solar PV cells are primarily manufactured from silicon, one of the most abundant materials on Earth. Silicon is found in sand and quartz. To make solar cells, high purity silicon is needed. The silicon is refined through multiple steps to reach 99.9999% purity. This hyper-purified silicon is known as solar grade silicon.

Why is silicon used in solar panels?

Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology. Silicon is found in 95% of solar modules today, showing its key role in solar energy. What makes silicon so important for the solar industry?

What is the difference between silicon and organic photovoltaics?

Crystalline silicon PV cells have achieved impressive efficiency rates of up to 27.3% in controlled research settings, while reliably delivering efficiencies between 20% and 22% under real-world conditions. In contrast, organic photovoltaics lag behind in efficiency, with current records topping out at 19.2% in laboratory conditions.

Update Information

- Kathmandu polycrystalline silicon solar photovoltaic panels

- Photovoltaic silicon is solar panels

- Silicon for Solar Photovoltaic Panels

- Urgent sale of a batch of solar photovoltaic panels

- Niamey s new solar photovoltaic panels

- Solar panels photovoltaic power generation in Pakistan

- What is the price of photovoltaic solar panels

- Kuwait carport photovoltaic solar panels

- Cuban home solar photovoltaic panels

- Photovoltaic solar panels in the sun room

- Myanmar solar panels photovoltaic panels

- Photovoltaic panels for solar energy

- Lithium iron phosphate for solar photovoltaic panels

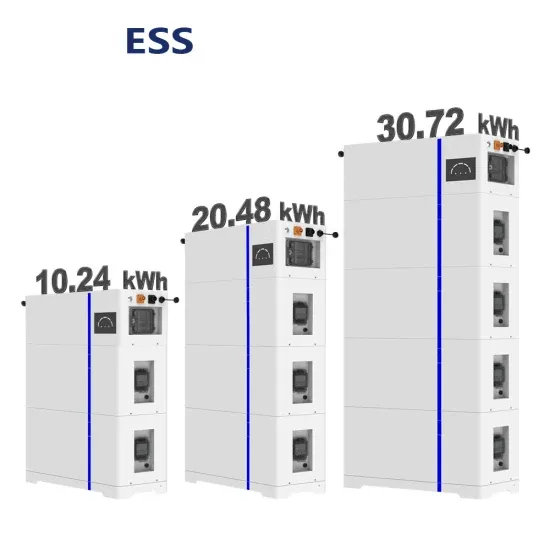

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.