Monocrystalline VS Polycrystalline Solar PV Modules

Jun 20, 2024 · Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the solar

Performance comparison of monocrystalline and polycrystalline

Nov 23, 2024 · According to Pastuszak (Pastuszak & Węgierek, 2022), in the article ''Photovoltaic Cell Generations and Current Research Directions for Their Development'', there have been

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Top Solar Panel Manufacturers Suppliers in Nepal

Aug 7, 2025 · Wholesale Solar Panels For Sale Homeowners and all types of businesses these days are seeking ways to cut down on their power consumption bill and reduce the overall

A Comparative Analysis and Performance of

Mar 7, 2022 · Abstract:- The spectrum of solar energy is quite wide and its intensity varies according to the timings of the day and geographic locations. This solar energy can be

Polycrystalline silicon solar cells

Jan 1, 2021 · The silicon demand for photovoltaic applications will be increased. The relations among the manufacturers of polycrystalline silicon with demand in the market from 2003 to

Polycrystalline silicon solar cells

Jan 1, 2021 · The production of polycrystalline silicon is a very important factor for solar cell technology. Brazil produces metallurgical silicon by reserving the quartz, which is a raw material.

Demystifying Polycrystalline Solar Panels: How They Operate

Oct 11, 2024 · Asked Questions Polycrystalline solar panels are primarily made of semiconductor materials, with silicon being the most common material used in their construction.

Comparison Between Monocrystalline Silicon Photovoltaic Panels

The photovoltaic conversion efficiency of monocrystalline silicon solar panels is generally higher than that of polycrystalline silicon panels, with top-tier monocrystalline panels achieving

Performance comparison of monocrystalline and

Nov 23, 2024 · Polycrystalline solar or PV cells are produced by melting silicon crystals, pouring them into a square mold, and cooling them. This pro-cedure generates numerous distinct

Modeling and Simulation of Polycrystalline Silicon Photovoltaic

Dec 11, 2019 · The smart grid system can be integrated from different sources of renewable energy, such as photovoltaic panels, built by a large number of solar cells. The aim

What are polycrystalline silicon solar cells?

Sep 22, 2024 · In summary, polycrystalline silicon solar cells represent a crucial facet of the solar energy landscape, characterized by their unique advantages

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

A Holistic Review of the Effects of Dust Buildup on Solar Photovoltaic

Nov 30, 2024 · PDF | On Dec 1, 2024, Sufyan Yakubu and others published A Holistic Review of the Effects of Dust Buildup on Solar Photovoltaic Panel Efficiency | Find, read and cite all the

Enhancing power conversion efficiency of polycrystalline silicon

Nov 1, 2024 · The study attempts to boost the power conversion efficiency of polycrystalline silicon (Si) photovoltaic cells by the application of anti-reflective coating (ARC). The solgel

Performance analysis of mono crystalline, poly crystalline and

Dec 1, 2021 · PV materials fall into three categories: crystallized silicon, thin film technology, and new emerging technologies as shown in Fig. 1 (a). Silicon is one of the most prevalent

Poly Crystalline Silicon Panels: Are They the Best

Aug 9, 2022 · They have their structural frame, which makes mounting simpler and cheaper. They''re the only solar panels that make you eligible to avail of a

A holistic review of the effects of dust buildup on solar photovoltaic

Mar 1, 2025 · The installation characteristics, such as the height of the panels and their orientation, further exacerbate or mitigate the impact of soiling. This study has been designed

The Basics of Polycrystalline Solar Panels and

Aug 18, 2025 · Made from multiple silicon crystals fused together, polycrystalline solar panels are able to convert sunlight into electricity by harnessing the

Specifications and models of polycrystalline silicon

Working Principle of polycrystalline solar panels: A polycrystalline solar panel is made up of several photovoltaic cells, each of which contains silicon crystals that serve as

Microstructural and phase degradation of monocrystalline solar

Jul 15, 2025 · The durability of solar photovoltaic (PV) panels in desert environments is critical for sustainable energy production. This study investigates the microstructural degradation of

Polycrystalline Solar Panels Explained

Aug 13, 2025 · Find out everything about polycrystalline solar panels, including their definition, efficiency, pros and cons, and pricing details with Soly''s expert guide.

Monocrystalline Vs Polycrystalline Solar PV Panels: 2024

Mar 14, 2024 · When you evaluate solar panels for photovoltaic systems, you will encounter two broad categories of panels: monocrystalline vs polycrystalline solar pv panels. This article

Specifications and models of polycrystalline silicon

Basic polycrystalline silicon based solar cells with a total area efficiency of app. 5% has been fabricated without the involvement of anti-reflecting coating. This is a resonable

Crystalline and Polycrystalline Silicon PV Technology

Feb 24, 2011 · Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of the world total PV cell production in 2008. The highest

6 FAQs about [Kathmandu polycrystalline silicon solar photovoltaic panels]

What are crystalline silicon PV cells?

Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of the world total PV cell production in 2008. The highest energy conversion efficiency reported so far for research crystalline silicon PV cells is 25%.

What are crystalline silicon solar cells?

Crystalline silicon PV cells are the most popular solar cells on the market and also provide the highest energy conversion efficiencies of all commercial solar cells and modules. The structure of typical commercial crystalline-silicon PV cells is shown in Figure 1.

What is a monocrystalline PV module?

(a) Classification of PV materials (b) Monocrystalline PV Module (c) Polycrystalline PV Module (d) Thin-film PV Module. Monocrystalline is created by slicing cells from a single cylindrical silicon crystal. Monocrystalline silicon needs a more complex manufacturing process than other technologies, resulting in slightly higher costs .

Which material is most commonly used in solar PV technology?

Silicon is one of the most prevalent materials in solar PV technology, according to . PV modules of the first generation were made of silicon with a crystalline structure. The two most basic varieties of crystalline technology are monocrystalline & multicrystalline. Fig. 1.

What industries are related to crystalline silicon solar cell and module production?

There are generally three industries related to crystalline silicon solar cell and module production: metallurgical and chemical plants for raw material silicon production, monocrystalline and polycrystalline ingot fabrication and wafer fabrication by multi-wire saw, and solar cell and module production.

How are monocrystalline solar cells made?

Monocrystalline solar cells are produced from pseudo‐square silicon wafer substrates cut from column ingots grown by the Czochralski (CZ) process. Polycrystalline cells, on the other hand, are made from square silicon substrates cut from polycrystalline ingots grown in quartz crucibles.

Update Information

- Polycrystalline silicon solar photovoltaic panels

- Silicon for Solar Photovoltaic Panels

- Solar photovoltaic silicon panels

- New solar photovoltaic panels in Sydney Australia

- Photovoltaic solar panels for roof waterproofing

- The impact of photovoltaic solar panels on the climate

- Yaounde Solar Photovoltaic Panels

- Photovoltaic solar panels installed in Hungary

- Photovoltaic solar panels in rural Alexandria Egypt

- Beirut Photovoltaic Panels Greenhouse Solar Energy

- Understanding Photovoltaic Solar Panels

- New solar photovoltaic panels in Alexandria Egypt

- Photovoltaic solar panels installed in Cambodia

Solar Storage Container Market Growth

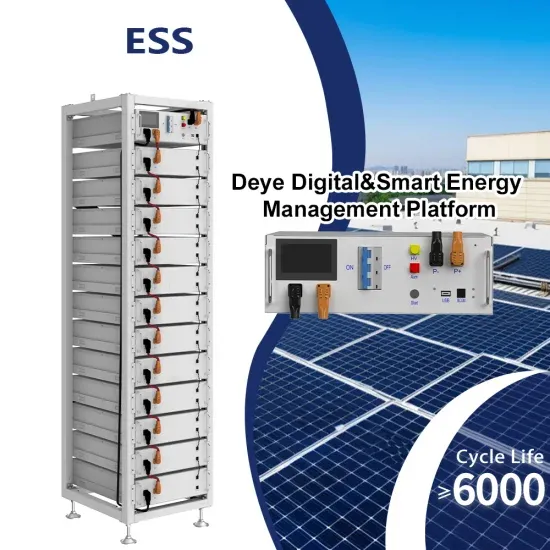

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.