BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Jul 22, 2025 · Comprehensive guide to BMS for lithium-ion batteries. Learn battery management system functions, safety features, and protection mechanisms in 2025.

MATLAB/SIMULINK BASED STUDY ON BATTERY

Jul 9, 2025 · I. INTRODUCTION Battery management system (BMS) is a managerial technique, which helps in monitor and calculating the diverse parameters of rechargeable batteries. BMS

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · BMS is like a 24-hour on duty ''battery doctor'', mainly responsible for completing six major tasks: Collect voltage, current, temperature and other data to ensure transparency of

BMS – Knowledge and References – Taylor & Francis

A battery management system (BMS) is an electronic device that monitors and manages the parameters of a battery system, such as voltage, temperature, current, and state of charge

Relationship between BMS and battery capacity

Battery Capacity Display: Understanding Measurements And Understanding the relationship between voltage and battery capacity starts with recognizing that battery capacity is often

Modeling of Cell Balancing, Battery Aging and

Jul 15, 2021 · Figure 11 depicts the aging model of a Lithium-Ion battery and with the help of this model, the relationship between several parameters of a lithium-ion battery pack i.e., voltage,

BMS Confusion: Understanding the Difference Between Battery

Both systems use the same acronym—BMS—which leads to confusion. Here''s a simple way to remember the difference: Battery Monitoring System = External oversight (like a medical

How Battery Management Systems (BMS) Prevent Battery

Apr 22, 2025 · The BMS monitors and manages various aspects of battery operation, ensuring efficient and reliable performance. Learn how its role can help users prevent battery failures

BMS battery management system and mechanical relationship

A battery management system (BMS) is a system control the overall energy efficiency of grid-connected storage systems considering the actual relationship between the efficiency and the

BMS Power Management and the Relationship with Battery Life

At the same time, the BMS can adjust management strategies based on the actual usage of the battery, achieving continuous optimization of battery performance and life extension. In

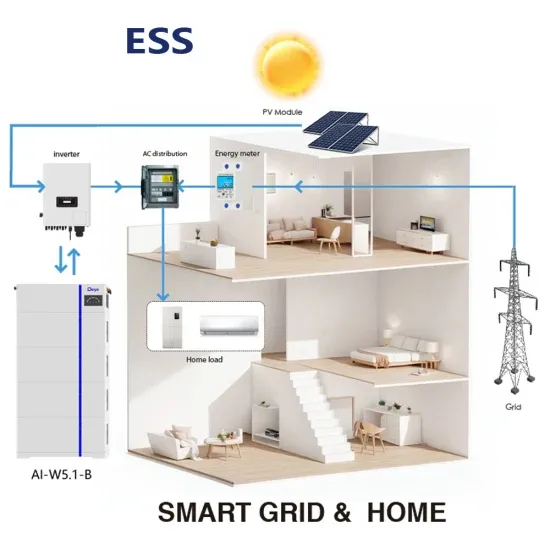

Grid-connected battery energy storage system: a review on

Aug 1, 2023 · Battery energy storage systems (BESSs) have become increasingly crucial in the modern power system due to temporal imbalances between electricity supply and demand.

Battery Packs & BMS Synergy for EV Safety and Performance

In the world of electric vehicles (EVs), the seamless synergy between battery packs and Battery Management Systems (BMS) plays a crucial role in ensuring optimal performance, longevity,

6 FAQs about [Relationship between battery park and BMS]

What is battery management system (BMS)?

Battery Management System (BMS) role in battery packs and energy storage system is critical to ensure safe operation and extend lifetime.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

Why is BMS important in a battery system?

primary system are vital for the battery system’s performance optimization. BMS can accordingly. Sometimes, its main system structure may need to change the working strategy according to the battery’s performance. In such a case, BMS is the only thing battery pack. 2.4. T esting

Does BMS protect the battery system cell/pack paameters?

BMS can protect the battery system cell/pack paameters. Two types o temperatures—electrochemical reacton temperature safety. BMS can ensure control of these two types of battery temperaures within their and protects the loss o battery heating controls (BSS). Kokkotis et al. dscussed the electrochemical means of EES systems such as batteries.

What are the hazards associated with BMS operation within battery systems?

T able 3presents the potential hazards related to BMS operation within battery systems. T able 3. Operational BMS hazards. 1. Loss of air conditioning and battery cooling (BSS—battery support system). 2. Loss of battery heating controls (BSS). 3. Loss of battery voltage control function (BMS/EMS). 4.

What is a BMS battery pack?

and battery environment temperature—can be controlled in the battery pack for BMS safety. BMS can ensure control of these two types of battery temperatures within their safety limit. systems. It allows protection of loss of air conditioning and battery cooling and protects the loss of battery heating controls (BSS).

Update Information

- Professional BMS battery management system function introduction

- Brunei power lithium battery bms solution

- BMS battery management system power off

- Battery Management System BMS Electrical

- Bms sends battery voltage

- Shanghai bms lithium battery

- Windhoek BMS battery management power system composition

- Dushanbe lithium iron phosphate bms battery

- Lithium battery pack active balancing BMS passive balancing

- Somalia BMS battery management power system manufacturer

- The role of Haiti BMS battery management system

- Battery Control BMS

- Guinea new energy lithium battery bms system

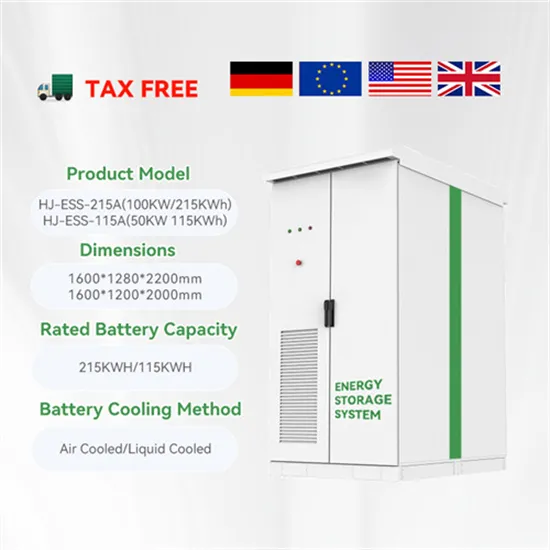

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.