Understanding the Role of the BMS in Modern Lithium Batteries

Aug 19, 2025 · The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect

A Strategy for Measuring Voltage, Current and

Nov 24, 2022 · Input voltage, current, and temperature measurement circuits are the vital concerns of a Battery Management System (BMS) in electric vehicles.

Battery management system sends message

The BMS sends the overall status message of the power battery to the on-board charger, and monitors the charging status such as the charging voltage and charging current of the battery

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Voltage detection: The voltage of each battery cell needs to be accurate to ± 1mV (equivalent to measuring the weight of a drop of water). Current detection: Calculate the

A Beginner''s Guide to Battery Management System

Apr 1, 2025 · Below is a simple introduction to common terms related to Battery Management Systems (BMS), designed to help beginners understand the basics. This guide covers "1S,"

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · In the world of lithium-ion batteries, the term "BMS battery" has become increasingly common — especially among manufacturers, engineers, and consumers of

How determine if BMS for a 12V LifePo4 can set charge rate?

Dec 19, 2024 · We''re considering affordable 12V Lifepo4 batteries for a vehicle. How do we evaluate batteries to determine if they can set their charge rate? There are lots of stats, and

Understanding the Role of BMS, EMS, and PCS in Battery

Jan 10, 2025 · The Battery Management System (BMS) is the brain of the battery, focusing on monitoring, protecting, and optimizing battery performance. It continuously tracks essential

Battery Management System (BMS) for Efficiency and Safety

Jan 5, 2025 · What Is a Battery Management System (BMS)? A Battery Management System (BMS) is an electronic system designed to monitor, regulate, and protect rechargeable

How to Wake Up a Lithium-Ion Battery (The Safe Way)?

Jul 30, 2025 · Its primary role is to keep the battery safe. When you store a device for an extended period, the battery gradually loses power through a process called self-discharge. If

EIS: The Next Phase for EV Battery-Management Systems?

Mar 3, 2025 · Every commercial BMS collects lots of data. Typically, it measures the voltage of every battery cell and the voltage and current of the pack.

Bms Book Simplified Guide | PDF | Lithium Ion Battery

3 days ago · Simplified Chapter-wise Guide: Battery Management Systems for Large Lithium-Ion Battery Packs by Phil Weicker 📘 Chapter 1: Introduction to BMS • Key Concepts: What is a

Battery Management System (BMS) in Battery Energy

Sep 15, 2024 · Learn about the role of Battery Management Systems (BMS) in Battery Energy Storage Systems (BESS). Explore its key functions, architecture, and how it enhances safety,

Section 2 Battery Management System (BMS) and

Dec 31, 2024 · ich is controlled by low voltage that is applied from the BMS. When a low voltage signal from the BMS is sent to the contactor, the contactor will energize and connect the

What Is a BMS? Battery Management System Explained

Aug 15, 2025 · Continuously measures individual cell voltage to ensure they stay within safe limits (e.g., 2.5–4.2V for Li-ion). Tracks thermal performance; activates cooling or disconnection

Exactly HOW does the BMS Stop the Charging Process?

Oct 26, 2023 · The battery is capable of rising to and meeting that voltage. Maybe the concept to grasp is voltage current interaction. If the charger is at a voltage, and the battery is at the

BMS Protection Functions for Lithium Battery Pack

Sep 10, 2020 · Overvoltage Protection The voltage of a single cell in the battery pack exceeds the allowable voltage. According to the purpose of protection,

Understanding Battery Management Systems: The Inside

Jun 12, 2025 · Why Battery Management Systems Matter Ever wondered what keeps your electric car running smoothly? Or how your laptop stays powered for hours? The secret sauce is the

Battery Management System (BMS): Diagrams & IC Selection

Aug 19, 2025 · What is a Battery Management System (BMS)? A Battery Management System (BMS) is the electronics that monitor cell and pack voltage, current, and temperature; estimate

CAN based protocol implementation between battery

Aug 24, 2019 · The aim of our study is to implement a CAN protocol for communication between the battery charger and the Battery management system or BMS. This makes the battery

6 FAQs about [Bms sends battery voltage]

What is a battery management system (BMS)?

It manages the status of the cells, ensures their consistency, and keeps them from being overcharged, under-discharged, and overheating. The BMS monitors the individual cell voltage of every lithium-ion cell check, checks for its temperature, and monitors the charging and discharging current of the system.

Does a BMS improve battery life?

Yes, by managing charging rates, temperature, voltage, and performing cell balancing, the BMS helps reduce wear and tear on the battery. This ultimately extends the battery's lifespan and ensures optimal performance over time. How does the BMS affect the EV's driving range?

How does a battery management system work?

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery. 2. Cell Balancing During charging, cells can become unbalanced.

Why does the BMS stop charging?

The BMS will stop charging to prevent overcharging. If the voltage drops below 2.5V, the battery could be damaged and have reduced capacity. The BMS will stop discharging to protect the battery from over-discharging. 2. State of Charge (SOC) Calculation (Lithium-Ion Battery Example)

What is a BMS & how does it work?

Step by step analysis BMS is like a 24-hour on duty ‘battery doctor’, mainly responsible for completing six major tasks: Collect voltage, current, temperature and other data to ensure transparency of battery status. Eliminate the power difference between battery cells and avoid the “barrel effect”. 2、 How does BMS work? Step by step analysis 1.

How does a BMS protect a lithium ion battery?

The BMS may stop charging or use heating elements to bring the battery back to a safer temperature. By maintaining the right temperature range, the BMS protects the Lithium-Ion battery from damage and optimizes its performance. 6. Charging and Discharging Control (Lithium-Ion Battery Example)

Update Information

- BMS battery voltage collection accuracy requirements

- Power battery BMS supporting

- Solar lithium battery bms management system

- Djibouti energy storage BMS battery management system

- BMS battery management manufacturer in Manchester UK

- BMS battery management system increases power consumption

- Communication base station battery bms

- What are the functions of battery BMS

- Relationship between battery park and BMS

- Uzbekistan lithium battery bms development

- Tirana BMS battery management control system manufacturer

- Operating voltage of vanadium liquid flow battery

- San Diego Lithium Titanate Battery Pack BMS

Solar Storage Container Market Growth

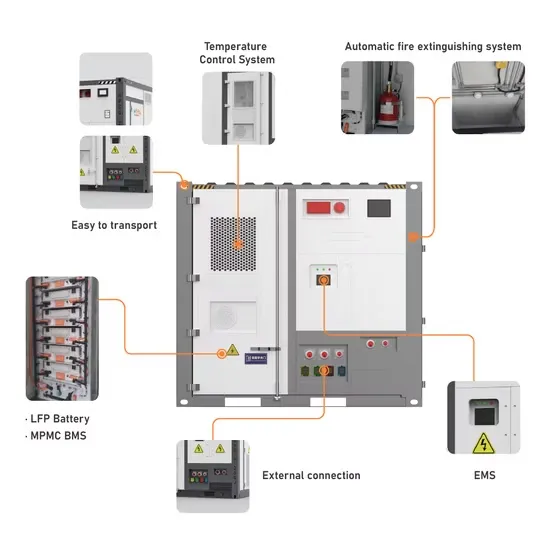

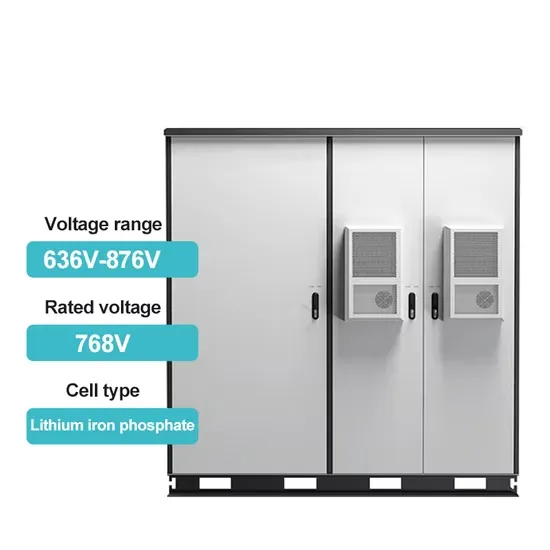

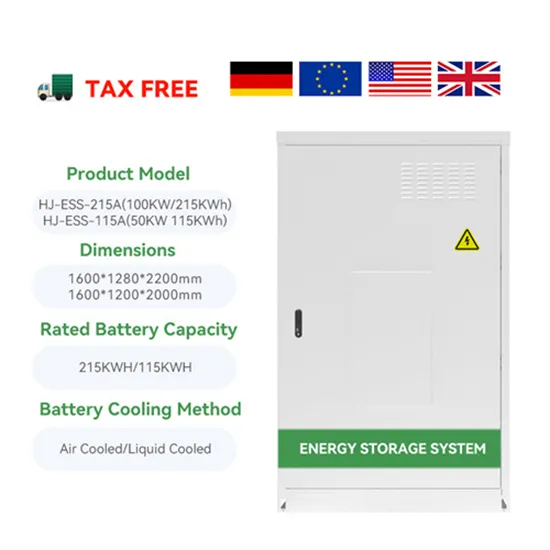

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.