The role of fuel cells in energy storage

Mar 1, 2000 · Fuel cells are becoming widely accepted as a preferred means of generating electricity for distributed electrical power generation because of their high fuel conversion

Sodium-air fuel cell for high energy density and

Jun 18, 2025 · This work demonstrates a new type of metal-air fuel cell utilizing liquid sodium metal, a solid electrolyte membrane, and humidified air, which

High Temperature Fuel Cell Tri-Generation of

infrastructure An emerging fuels (@ STP) strategy is poly-generation • H2 handling of hydrogen, (storage, transport and dispensing) can be energy and emissions intensive heat and power

New Ammonia-Based Fuel Cells Enable CO₂-Free Power

Nov 4, 2024 · Fraunhofer unveils a high-temperature fuel cell technology that converts ammonia directly into electricity, delivering a 60% efficient, climate-friendly solution for industries and

Development and Demonstration of a Novel

Jan 17, 2017 · There has been particular interest in reversible solid oxide fuel cells (RSOFCs) in the energy sector for electricity, energy storage, grid stabilization

Analysis of the Thermal Management of a High

Sep 18, 2021 · This work shows the feasibility of increasing the energy efficiency of a high-temperature methanol fuel cell using a latent heat storage with the

Molten carbonates for advanced and sustainable energy applications

Nov 9, 2016 · Unprecedented interest for clean and sustainable energy innovation has recently stimulated a return of attention on molten alkali carbonate salts not only for traditional use as

Technical Targets for High Temperature Electrolysis

4 days ago · This table summarizes the U.S. Department of Energy technical targets for high temperature electrolysis to achieve the central goal of low-cost hydrogen production of $2/kg

Fuel cells for multirotor unmanned aerial vehicles: A

Sep 1, 2024 · Hydrogen fuel cells and the economics of unmanned aerial vehicles (UAVs) are gaining global attention. With higher energy densities, fuel cells can overcome the range

Modeling, thermodynamic performance analysis, and

Apr 1, 2024 · There are many types of fuel cells, such as alkaline fuel cells (AFCs), proton exchange membrane fuel cells (PEMFCs), and phosphoric acid fuel cells (PAFCs). AFC

Hydrogen storage systems for fuel cells: Comparison between high

Jun 7, 2019 · The need for the enhancement of alternative energy sources is increasingly recognised and, in this perspective, the achievement of hydrogen economy seems to be

Self-assembled network polymer electrolyte membranes for

Jun 4, 2024 · High-temperature operation of polymer electrolyte membrane fuel cells has some advantages but is also challenging due to the instability of proton transport above 160 °C. Here

Advancement of fuel cells and electrolyzers technologies and

Jun 1, 2023 · Control of high-energy high-power densities storage devices by Li-ion battery and supercapacitor for fuel cell/photovoltaic hybrid power plant for autonomous system applications

Performance evaluation for a high temperature alkaline fuel cell

Jan 1, 2025 · This study is the first to integrate high-temperature alkaline fuel cells (AFC) with thermal vapor compression desalination (TVC) driven by steam ejectors. The proposed AFC

Fuel cells: A technical, environmental, and economic outlook

Jun 1, 2025 · In the pursuit of establishing a sustainable fuel cell (FC) energy system, this review highlights the necessity of examining the operational principles, technical details,

A comprehensive review on high-temperature fuel cells with

Oct 1, 2020 · Several novel CO 2 capture strategies have been developed based on high-temperature fuel cells, such as solid oxide fuel cell (SOFC), molten carbonate fuel cell (MCFC)

(PDF) Fuel Cells: Technologies and Applications

Jul 19, 2013 · PDF | A deep analysis of the Fuel Cells technologies state of the art has been done in this article. After a general description of the fuel cell base

Fuel cells with an operational range of –20 °C to 200 °C

Jan 3, 2022 · Most proton exchange membrane fuel cells are designed to operate within a temperature range of a few tens of degrees, but functioning in a broader range of conditions

High-Temperature Fuel Cells for Zero-Carbon Electricity

Jan 28, 2025 · This chapter is devoted to address the latter topic and provides an overview of high-temperature fuel cells for efficient and environmentally "clean" power generation from

High Temperature Fuel Cells

Jan 16, 2025 · The U.S. Department of Energy (DOE) is proposing to administer Congressionally Directed Spending to the Colorado School of Mines (CSM) to design, fabricate, commission,

Evolution of the electrochemical interface in high-temperature fuel

Jan 11, 2016 · Solid oxide electrolytes are the basis of two important energy technologies, solid oxide fuel cells (SOFCs) and solid oxide electrolyser cells (SOECs) that are jointly referred to

Working conditions of an Energy Storage System based on a high

Apr 8, 2016 · In this paper, a Fuel Cell based Energy Storage System (FC-ESS) was investigated for enhancing the range of a electrical commuter vehicle. While using a special

High-Temperature Fuel Cells for Zero-Carbon Electricity

Jan 28, 2025 · Hence, the terminology "carbon fuel cells" (CFC) is adopted here to describe all types of high-temperature fuel cell architectures that utilize and convert solid carbonaceous

Analysis of the Thermal Management of a High

Jun 22, 2021 · In this work, a detailed analysis of the thermal management of a high temperature methanol fuel cell (FC) with the help of a latent heat storage is given. A cylindrical LHS with

A polymer nanocomposite for high-temperature

Jan 15, 2025 · Ge et al. report a method for improving the discharge performance and temperature stability of polymer dielectric capacitors. By structure design

6 FAQs about [Energy Storage High Temperature Fuel Cell]

What is a high-temperature fuel cell?

High-temperature fuel cell is an electrochemical device that converts chemical energy of fuel directly into electrical energy and heat energy when fuel and oxidant are supplied. It consists of electrolyte, anode and cathode. The anode and cathode are electronic conductors, and the electrolyte only conducts ionic species.

What are the advantages of high-temperature fuel cells?

High-temperature fuel cells offer several advantages over conventional power generation technologies, such as high electrical efficiency, high heat source temperature, high power density, simpler balance-of-plant (BoP), low particulate and gas emissions, low noise and stable power output (no spikes or electrical noise) .

What are high temperature proton exchange membrane fuel cells (HT-PEMFCs)?

High temperature proton exchange membrane fuel cells (HT-PEMFCs) are a promising energy conversion technology due to their quick reaction kinetics, high tolerance to CO impurities, and ease of heat

Can a high-temperature fuel cell capture CO2?

The configuration of such kind of system could facilitate an easy capture of CO 2. Several novel CO 2 capture strategies have been developed based on high-temperature fuel cells, such as solid oxide fuel cell (SOFC), molten carbonate fuel cell (MCFC) and direct carbon fuel cell (DCFC).

What is latent heat storage in a fuel cell?

Instead of cooling the fuel cell with air and losing the heat to the environment, the waste heat is now stored in a latent heat storage to later be used for preheating the fuel cell. Different experiments are conducted to find the optimum operation point of the latent heat storage in combination with the fuel cell.

Can a high temperature methanol fuel cell operate with a latent heat storage?

Inthiswork,adetailedanalysisofthethermalmanagementof a high temperature methanol fuel cell (FC) with the help of a latent heat storage is given. A cylindrical LHS with 2.4kWh ther- mal storage capacity is used to operate a fuel cell. HDPE with its melting temperature of 403K is used as PCM.

Update Information

- Vilnius Heneng Energy Storage Fuel Cell

- Nassau Hydrogen Fuel Cell Energy Storage Container

- Is the fuel cell electric an energy storage device

- Solar cell energy storage company in Sao Paulo Brazil

- Cost of high power energy storage device

- Dakka energy storage low temperature lithium battery

- High voltage resistors in energy storage systems

- Jamaica energy storage lithium battery cell

- Kyrgyzstan energy storage low temperature lithium battery

- 48v energy storage cell photovoltaic panel

- Solar cell capacitor energy storage

- Havana Energy Storage Temperature Control System Price

- Communication base station solar cell energy storage cabinet production

Solar Storage Container Market Growth

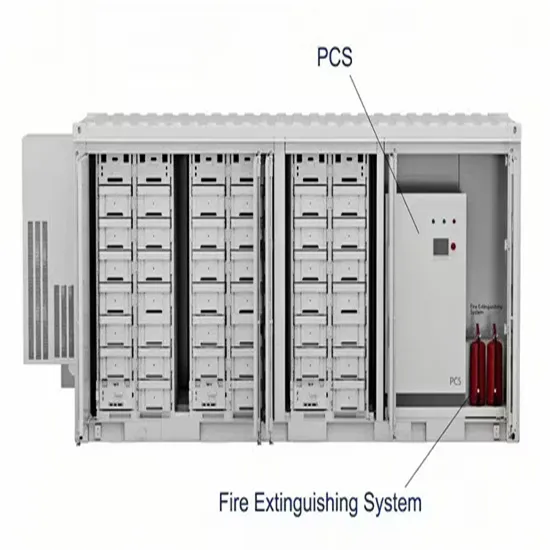

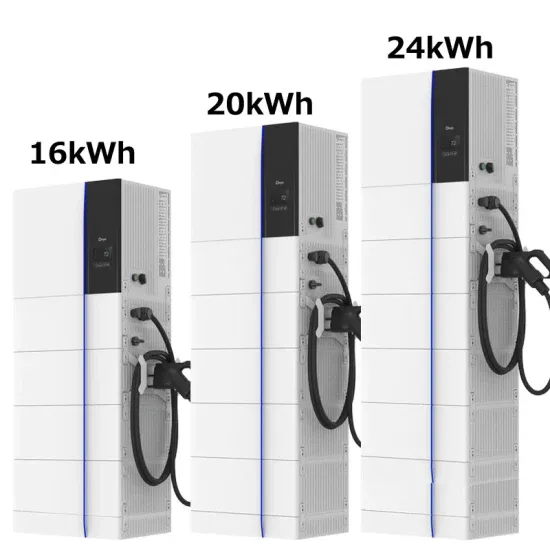

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.