Hydrogen and Fuel Cell Activities and Progress

Using H2 for large scale applications aligns with H2@Scale and can enable energy security, economic value and environmental benefits. Maritime applications can play a role. Conduct

Hydrogen storage for fuel cell vehicles

Aug 1, 2014 · A major obstacle for the development of hydrogen powered fuel cell vehicles is the lack of safe, light weight and energy efficient means for on-board hydrogen storage. During the

Proteus Unveils Hydrogen Fuel Cell System for Shipping

Jun 18, 2025 · The fuel cell stacks are built at Symbio''s gigafactory in Lyon, ensuring high-volume production with automotive-grade quality. Proteus is also offering DNV type-approved high

Maritime Fuel Cell Generator Project

Jun 7, 2017 · We have built and deployed a containerized hydrogen fuel cell generator for reefer power on land and sea. Fuel cell unit replaces diesel generators, reducing fuel cost and

Hydrogen Fuel Cell Applications in Ports:

Oct 28, 2019 · • What role can converting auxiliary power systems play in the adoption of fuel cell/hydrogen technology on containerships? Hydrogen Port Clusters (H2PC) will typically be

Advancements in hydrogen storage technologies: A

Jun 1, 2024 · Hydrogen offers advantages as an energy carrier, including a high energy content per unit weight (∼ 120 MJ kg –1) and zero greenhouse gas emissions in fuel-cell-based power

WHAT IS A PORTABLE HYDROGEN FUEL CELL SYSTEM

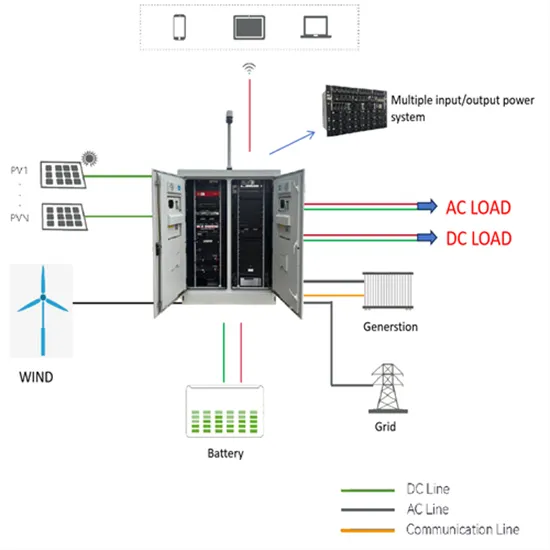

Principle of hydrogen fuel cell energy storage cabinet This paper presents a review of fuel cells including Energy Storage Using Hydrogen Produced from Excess Renewable Electricity, as

Reversible Fuel Cell Cost Analysis

5 days ago · The extent to which hydrogen energy storage costs can be reduced by consolidating electrolyzers and fuel cell stacks in a unitized, reversible fuel cell. The role of hydrogen for long

Hydrogen Fuel Cell Applications in Ports:

Oct 28, 2019 · Develop fuel cell use profile for auxiliary power systems that includes all forms of hoteling load Identify associated ship design standards for onboard fuel cell systems,

Review of Energy Storage Devices: Fuel Cells,

Nov 4, 2024 · In fuel cells, electrical energy is generated from chemical energy stored in the fuel. Fuel cells are clean and efficient sources of energy as

Hydrogen and Fuel Cell Technologies Program: Storage

Feb 16, 2011 · Hydrogen Storage Developing safe, reliable, compact, and cost-effective hydrogen storage tech-nologies is one of the most technically challenging barriers to the widespread use

Containerized Hydrogen Fuel Cell Power Plants

Dec 25, 2022 · At its core, the project uses lithium-ion batteries bigger than your neighbor''s swimming pool—300 megawatt-hours of storage capacity to be exact. But here''s the kicker:

Hydrogen Fuel Cells for Self-Sustaining Container Units

The future of hydrogen fuel cells in self-sustaining container units looks promising, with advancements in storage and efficiency driving wider adoption. By embracing this clean

3 FAQs about [Nassau Hydrogen Fuel Cell Energy Storage Container]

What is a containerized hydrogen fuel cell power plant?

Containerized Hydrogen Fuel Cell Power Plants can be used in remote locations such as islands, mines, temporary buildings, encampments Even as emergency generation units for many different applications such as data centers or hospitals. Providing a Zero emission alternative power source for such special needs.

What are the benefits of a containerized hydrogen fuel cell power plant?

Probably the most noticeable benefit of having the plant inside a standard container is easy transportation and its quick installation. And this provides important flexibility. Containerized Hydrogen Fuel Cell Power Plants can be used in remote locations such as islands, mines, temporary buildings, encampments

What is a hydrogen port cluster (H2Pc)?

Hydrogen Port Clusters (H2PC) will typically be part of a broader urban environment. Include stakeholders from the urban cluster to broaden hydrogen demand roadmap ► Stakeholders could include nearby airport(s) authorities, commuter rail supporting the urban environment, mass transit bus authorities, and advanced mobility vehicle (AMV) developers

Update Information

- Is the fuel cell electric an energy storage device

- Photovoltaic energy storage fuel cell

- Nassau Energy Storage Container Distribution Box Factory

- Vilnius Heneng Energy Storage Fuel Cell

- Kinshasa Energy Storage Container

- Belgrade photovoltaic energy storage container

- How big is a 5mwh energy storage container

- Austrian Liquid Cooling Energy Storage Container Company

- Energy storage battery container parameters base station

- Energy storage container automated production line

- Castrie container energy storage cabinet quotation

- How long does it take to install an energy storage container

- Solomon Islands Energy Storage Container Distribution Box

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.