Europe''s largest flow battery project launched to boost

Jun 18, 2025 · To mark the start of the construction phase, leaders from Flow Batteries Europe (FBE) and the FlexBase Group met in Laufenburg, Switzerland to solidify cooperation on

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · Finally, the scientific challenges and prospects of electrospun carbon fiber electrodes with maximized specific surface areas and hydraulic permeability are presented.

What you need to know about flow batteries

May 8, 2024 · What is unique about a flow battery? Flow batteries have a chemical battery foundation. In most flow batteries we find two liquified electrolytes (solutions) which flow and

Swiss developer breaks ground on 1.6 GWh redox flow

May 23, 2025 · Flexbase Group has begun construction on what could become one of Europe''s largest flow battery storage installations, breaking ground on an 800 MW/1.6 GWh redox flow

Construction of High-Performance Membranes for Vanadium Redox Flow

May 19, 2025 · Critically analyses the ion transport mechanisms of various membranes and compares them and highlights the challenges of membranes for vanadium redox flow battery

Flexbase Begins Construction on 800 MW Flow Battery in

Jun 18, 2025 · In a major stride for energy storage in Europe, Flexbase Group has commenced construction of an 800 MW / 1.6 GWh redox flow battery system in Laufenburg, Switzerland,

100MW/600MWh Vanadium Flow Battery Energy Storage

Jan 16, 2025 · Construction of a centralized control center and a multi-story steel-structured office and living area, covering 5,000 square meters. The Linzhou Fengyuan 300MW/1000MWh

Improvement of the Battery Performance of Vanadium Flow Battery

Mar 30, 2021 · Abstract Aiming at the shortcoming of low specific surface area of the most commonly used carbon felt (CF) electrodes in vanadium flow battery (VFB), there are mainly

A flow battery cell testing facility for versatile active material

Jan 1, 2025 · This includes valuable construction details for researchers interested in designing a testing facility for FB single cell or small stack, with a focus on hydraulic system, power

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

Construction approval for 1.6GWh flow battery in Switzerland

Jul 20, 2025 · Approval was announced in early April with official groundbreaking said then to to take place in the next few weeks, while commissioning is scheduled for 2028. It will be built at

Flexbase Begins Construction on 800 MW Flow Battery in

Jun 18, 2025 · Construction work on what Flow Batteries Europe (FBE) is calling the world''s largest flow battery started this month at the strategic critical electrical grid interconnection

Electrolyte tank costs are an overlooked factor in flow battery

Jan 3, 2025 · Electrolyte tank costs are often assumed insignificant in flow battery research. This work argues that these tanks can account for up to 40% of energy costs in large systems,

Europe''s Largest Flow Battery Project Launched to Boost

Jun 18, 2025 · Construction work for the world''s largest flow battery started last month at the strategic critical electrical grid interconnection point on the borders of Germany, France, and

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium''s ability to exist in several states. By using one

Vanadium Redox Flow Battery

3 days ago · The battery operates at ambient temperatures. Flow batteries are different from other batteries by having physically separated storage and power units. The volume of liquid

Vanadium redox flow batteries: A comprehensive review

Oct 1, 2019 · The simple design nature also includes ease and possibility for modular construction [35]. The simplicity of the redox flow battery and the reversible redox reaction along with the

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless

Sumitomo Electric''s Redox Flow Battery Selected

Mar 28, 2025 · Sumitomo Electric Industries, Ltd. is pleased to announce that its redox flow battery (hereinafter "RF battery") has been selected as a grid-scale

6 FAQs about [Flow battery construction area]

What is flow battery systems manufacturing?

The manufacturing of flow battery systems is the focus of the "$24.5 Million for Manufacturing Innovation" funding opportunity. Flow batteries are electrochemical batteries that use externally stored electrolytes, making them cost less, safer, and more flexible and adaptable. The funding opportunity will award up to $20 million for R&D projects in this area.

Where is Rongke Power completing a redox flow battery project?

The project in Ushi, China, taken from a video the company posted on LinkedIn. Image: Rongke Power via LinkedIn. Technology provider Rongke Power has completed a 175MW/700MWh vanadium redox flow battery project in China, the largest of its type in the world.

What is a flow battery?

Flow batteries are a type of electrochemical batteries that use externally stored electrolytes, making them cost less, safer, and more flexible and adaptable. They are particularly well-suited for grid storage needs. Flow batteries are not the same as lithium-ion batteries, which are commonly used in electric vehicles and portable devices for various applications.

Why is a flow battery important to China's Energy Future?

It also plays an important role in regulating energy supply and frequency, making it a key component of China’s sustainable energy future. Rongke Power, a pioneer in flow battery technology, previously developed the 100 MW/400 MWh Dalian system in 2022, the largest of its kind at the time.

What is the cost of a flow battery?

Flow batteries like the one developed by ESS could cost $200 per kWh or less by 2025. Importantly, adding more storage capacity to cover longer interruptions at a solar or wind plant may not require purchasing an entirely new battery. Flow batteries only require additional electrolyte, which in ESS’s case can cost as little as $20 per kilowatt hour.

Are flow batteries a viable alternative to pumped hydro energy storage?

Flow batteries are one of the most commercially mature LDES technologies, alongside pumped hydro energy storage (PHES), but still have a much higher capex requirement than lithium-ion batteries, which dominate the energy storage market today.

Update Information

- Ministry of Industry and Information Technology s communication base station flow battery construction specifications

- Spanish communication base station flow battery construction company

- Vientiane Electric Power Construction Zinc-Iron Liquid Flow Battery

- Brussels communication base station flow battery construction company

- Cambodia Communication Base Station Flow Battery Construction Regulations

- Osmotic flow battery

- Gigawatt-scale liquid flow battery smart factory

- South Korea communication base station flow battery lightning protection

- Namibia Flow Battery Wholesale

- Vanadium liquid flow battery effect

- Liquid Flow Battery for Panama Offshore Communication Base Station

- El Salvador s new all-vanadium flow battery electrolyte pump

- What does the flow battery for communication base stations do

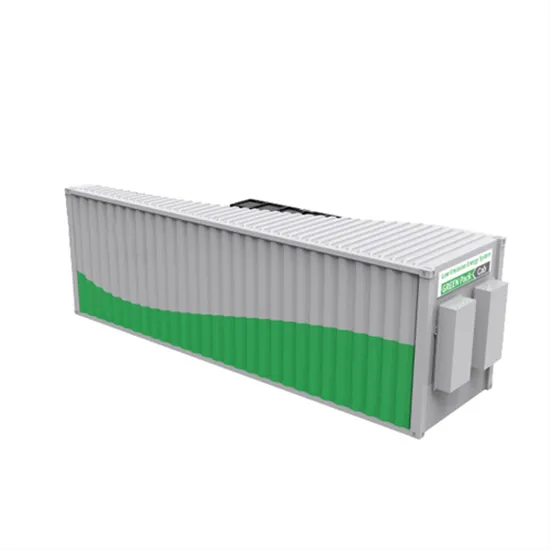

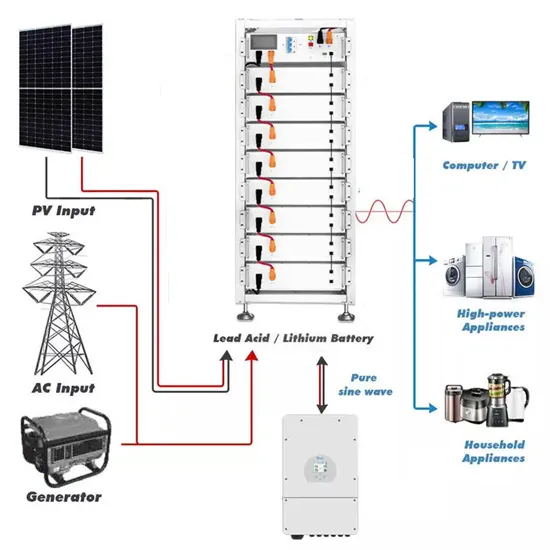

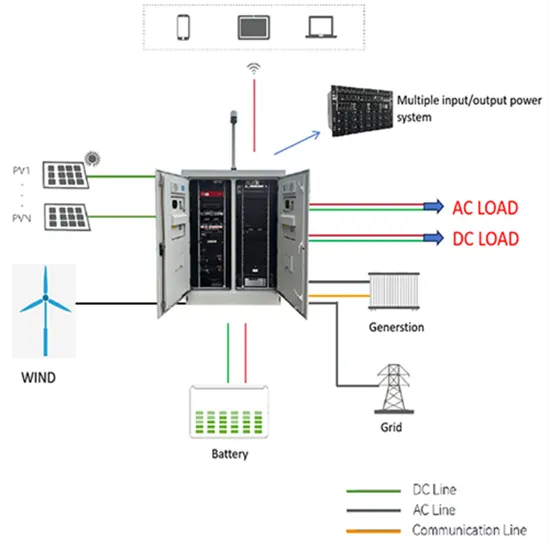

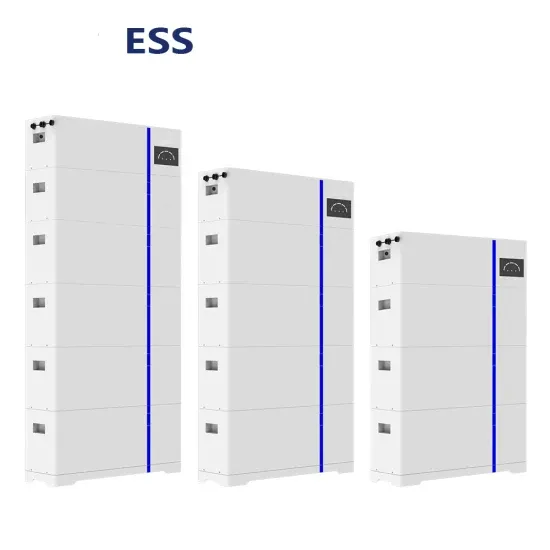

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.