PWM Inverter Output Voltage Calculation calculation for

Jan 25, 2024 · Popularity: ⭐⭐⭐ PWM Inverter Output Voltage Calculation This calculator provides the calculation of the output voltage of a PWM inverter. Explanation Calculation

Pulse Width Modulated (PWM) Drives

Jun 14, 2016 · Triangle Generator Modulation Generator PWM The triangular signal is the carrier or switching frequency of the inverter. The modulation generator produces a sine wave signal

PWM Inverter – Definition, Circuit Diagram & Advantages

Jul 10, 2021 · In this topic, you study PWM Inverter – Definition, Circuit Diagram & Advantages. PWM Inverter uses PWM (Pulse Width Modulation) technique to control the output voltage of

Theoretical harmonic spectra of PWM waveforms

Dec 4, 2021 · Abstract- This paper develops a new closed-form analytical solution to the harmonic spectrum of the Pulse Width Modulated (PWM) output voltage of the single-phase inverter

Harmonic Analysis of Output Voltage in PWM Inverters

Nov 7, 2018 · This paper presents a switching angle generation mechanism and calculation method of sinusoidal pulse width modulation (SPWM). Combining the calculated switching

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · Inverter Voltage Formula: Inverter voltage (VI) is an essential concept in electrical engineering, particularly in the design and operation of power electronics systems. It describes

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

Three-Phase Voltage Source Inverter

Feb 13, 2024 · 1 Overview This model shows a three-phase voltage source inverter (VSI). The VSI is an inverter circuit which cre-ates AC current and voltage from a DC voltage source.

Harmonic Analysis of Output Voltage in PWM Inverters

Nov 7, 2018 · Harmonic Analysis of Output Voltage in PWM Inverters Three-phase two-level pulse width modulation (PWM) inverters have recently been increasing applied due to better

Unipolar PWM Single Phase Inverter with RL Load

Oct 27, 2024 · Although unipolar PWM can reduce harmonic distortion compared to other modulation techniques, it may still result in higher total harmonic distortion in the output

Lecture 23: Three-Phase Inverters

Feb 24, 2025 · This inverter operation mode is sometimes aptly called "six-step" mode - cycles sequentially through six of the 8 states defned above. The other two states are "zero states"

Compensation method of PWM inverter output voltage

Apr 17, 2023 · This paper proposed a compensation method for the output voltage errors of a PWM inverter. Output voltage errors occur under low sampling-to-fundamental frequency ratio

TELKOMNIKA

Aug 10, 2021 · When the rotating voltage vector falls into a certain sector in a three-phase three-level inverter, adjacent voltage vectors are selected to synthesize the desired rotating voltage

Sinusoidal Pulse Width Modulation

The carrier-based PWM technique fulfills such a requirement as it defines the on and off states of the switches of the inverter legs by comparing a modulating signal vc (desired ac output

PWM Inverter Output Voltage Calculation calculation for

Jan 25, 2024 · This calculator provides the calculation of the output voltage of a PWM inverter. Calculation Example: The output voltage of a PWM inverter is given by Vout = Vin * D, where

Unipolar and Bipolar PWM Inverter

Dec 29, 2014 · The inverter terminal voltages are obtained denoted by VAN and VBN and the inverter output voltage VAB = VAN-VBN. Since the waveform of VAB switches between

Reduction of Harmonics in Output Voltage of Inverter

Mar 7, 2022 · PWM Techniques: The output voltage of an inverter can also be controlled by providing a control within the inverter itself. The most efficient methods of doing this is by pulse

6 FAQs about [Pwm inverter output voltage]

What is a PWM inverter?

An inverter whose functionality depends upon the pulse width modulation technology is referred to as PWM inverters. These are capable of maintaining the output voltages as the rated voltages depending on the country irrespective of the type of load connected. This can be achieved by changing the switching frequency width at the oscillator.

What is pulse width modulation (PWM) for inverters?

The concept of Pulse Width Modulation (PWM) for inverters is described with analyses extended to different kinds of PWM strategies. Finally the presented. battery or rectifier provides the dc supply to the inverter. The inverter is used to voltage. AC loads may require constant or adjustable voltage at their input terminals,

What is frequency regulation of a PWM inverter?

Frequency regulation of in this category of PWM of this inverter is done through varying the frequency of input control voltage. The PWM inverter changes condition numerous times through one cycle of the resultant output voltage.

Can a PWM inverter change the output voltage and frequency simultaneously?

The output voltage is directly proportional to the modulation index and input dc voltage, RMS voltage can be varied by varying modulation index and the instantaneous voltage can be varied by changing DC input voltage. Thus, the PWM inverter can vary the output voltage and frequency simultaneously.

How to reduce harmonic content in a PWM inverter?

The harmonic of lower order can be eliminated (removed) along with controlling the output voltage. Use of PWM Techniques reduces the harmonic content in the output (load) AC voltage. PWM inverter have less harmonic content compared to square wave inverter for same fundamental voltage.

What is the difference between two-level and three-level PWM inverters?

While the output voltage of a two-level PWM inverter takes either the zero or High level, three-level and multilevel PWM inverters provide the output voltage at multiple levels by dividing the input DC voltage. 7.1.1. Three-level PWM Table 7.1 compares two- and three-level inverters.

Update Information

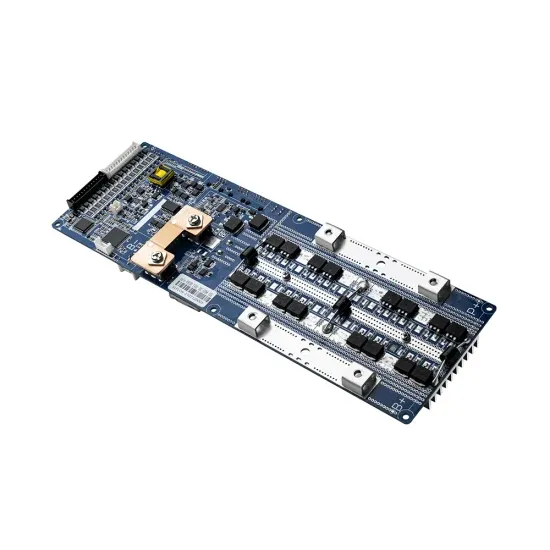

- Three-phase voltage type pwm inverter design

- String inverter output voltage

- Inverter can output voltage

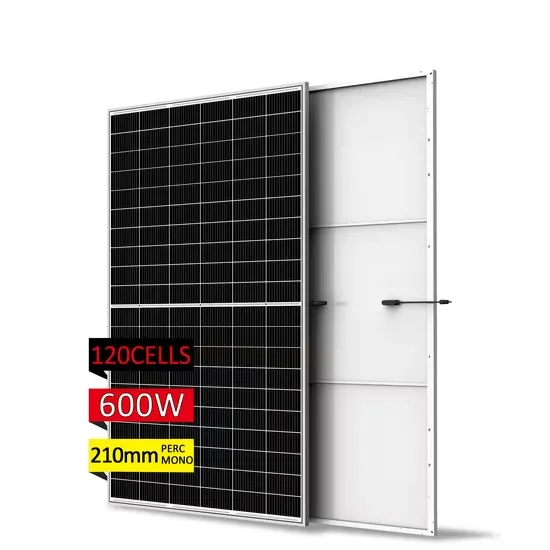

- Photovoltaic inverter and output voltage

- Inverter output voltage is slow

- Is the inverter output voltage 187V normal

- The output voltage of the inverter is symmetrical

- Wind power inverter output voltage

- Pwm voltage inverter

- What is a voltage tracking PWM inverter

- Inverter DC voltage measurement exceeds range

- What voltage should I buy for a 1000w inverter

- Is the higher the voltage of the inverter the better

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.